D2057A, D2058A, D2260A Mobile Base Instructions

Preparation for Assembly

There is more than one way to assemble the mobile base. Each method has advantages and disadvantages, depending on the size and weight of the machine that you plan to put on the mobile base. The purpose of this section is to help you decide which method will work best for your situation.

If the machine can be lifted, the easiest method is to assemble the mobile base according to the dimensions of your machine, and then lift and place the machine on the corner bracket pads of the mobile base (see Page 5).

If the machine is top heavy or has a narrow base (such as a drill press), there is an increased risk when moving it around on a mobile base. To reduce the risk, a mounting base plate should be used between the mobile base and machine (see Page 12).

If the machine is too heavy to lift into position on the mobile base, then the base can be built around the machine. For instructions on how to build the base around the machine, refer to Page 8.

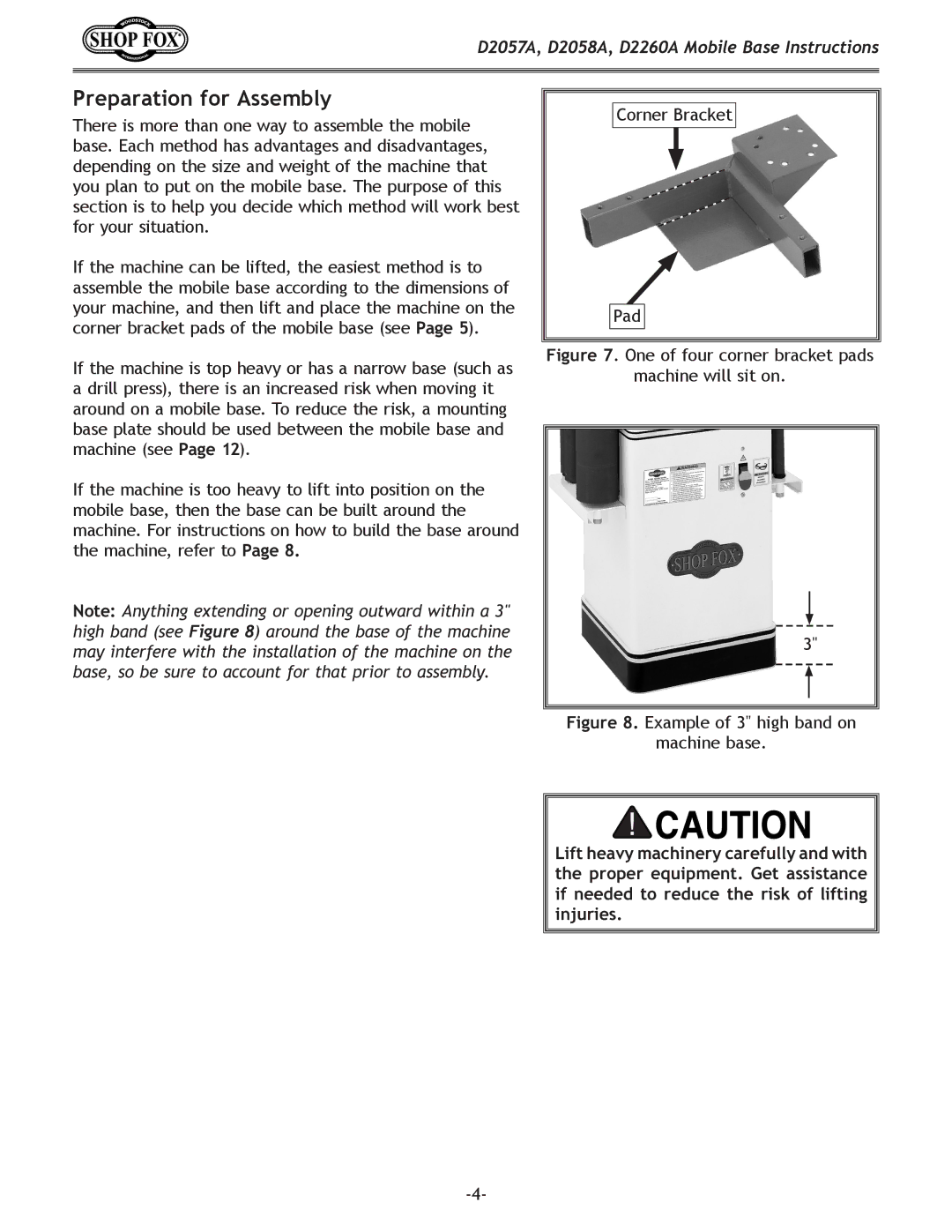

Note: Anything extending or opening outward within a 3" high band (see Figure 8) around the base of the machine may interfere with the installation of the machine on the base, so be sure to account for that prior to assembly.

Corner Bracket

Pad

Figure 7. One of four corner bracket pads

machine will sit on.

3"

Figure 8. Example of 3" high band on

machine base.

Lift heavy machinery carefully and with the proper equipment. Get assistance if needed to reduce the risk of lifting injuries.