M1001 6" x 26" Vertical Mill

Graduated Dials

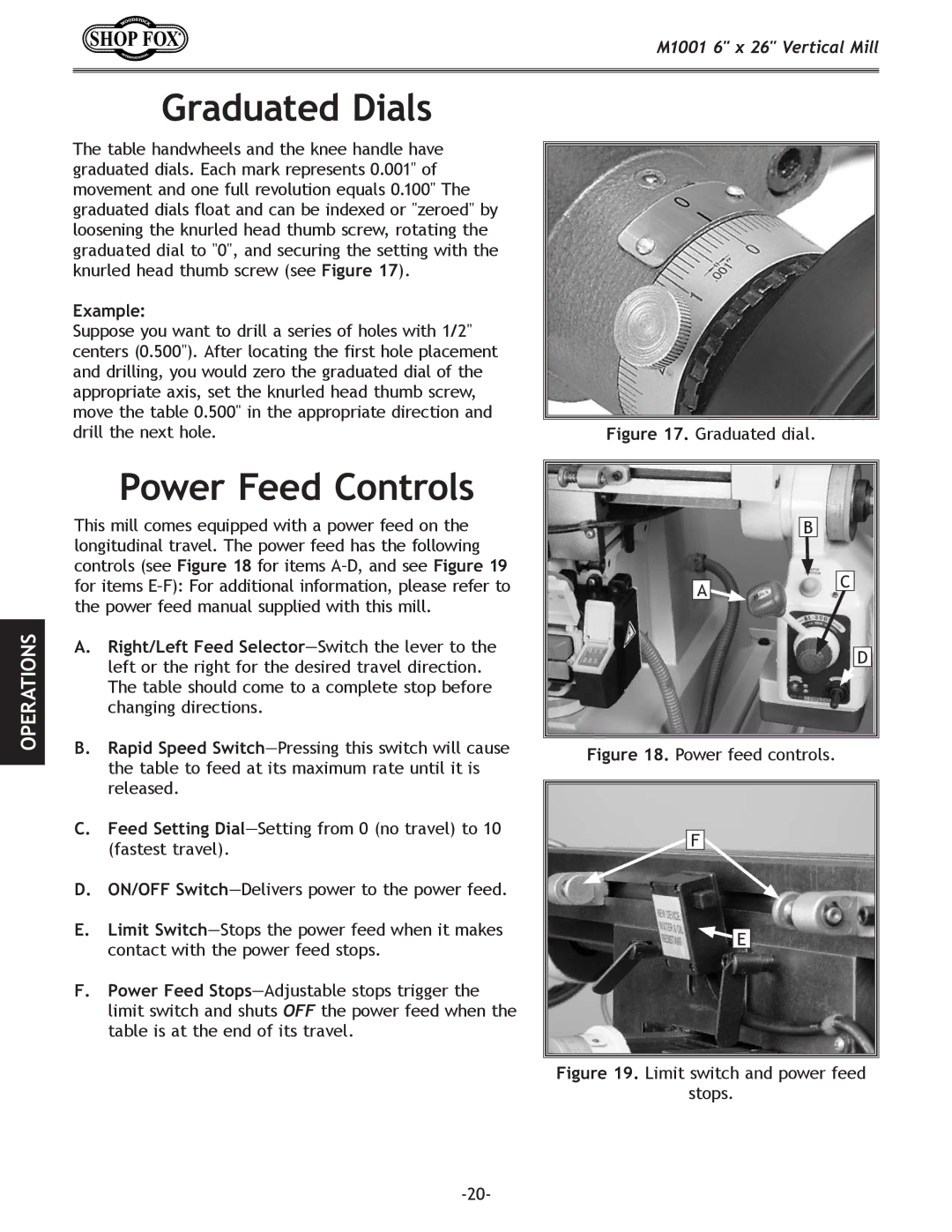

The table handwheels and the knee handle have graduated dials. Each mark represents 0.001" of movement and one full revolution equals 0.100" The graduated dials float and can be indexed or "zeroed" by loosening the knurled head thumb screw, rotating the graduated dial to "0", and securing the setting with the knurled head thumb screw (see Figure 17).

Example:

Suppose you want to drill a series of holes with 1/2" centers (0.500"). After locating the first hole placement and drilling, you would zero the graduated dial of the appropriate axis, set the knurled head thumb screw, move the table 0.500" in the appropriate direction and drill the next hole.

Figure 17. Graduated dial.

OPERATIONS

Power Feed Controls

This mill comes equipped with a power feed on the longitudinal travel. The power feed has the following controls (see Figure 18 for items

A.Right/Left Feed

B.Rapid Speed

C.Feed Setting

D.ON/OFF

E.Limit

F.Power Feed

B

A![]() C

C

D

Figure 18. Power feed controls.

F

![]()

![]() E

E