M1001 6" x 26" Vertical Mill

Assembly

SET UP

The Model M1001 comes fully assembled from the factory with the exception of one of the longitudinal handwheels and the cross handwheel. The head has been rotated to reduce the overall dimension of the shipping crate.

Headstock Adjustment

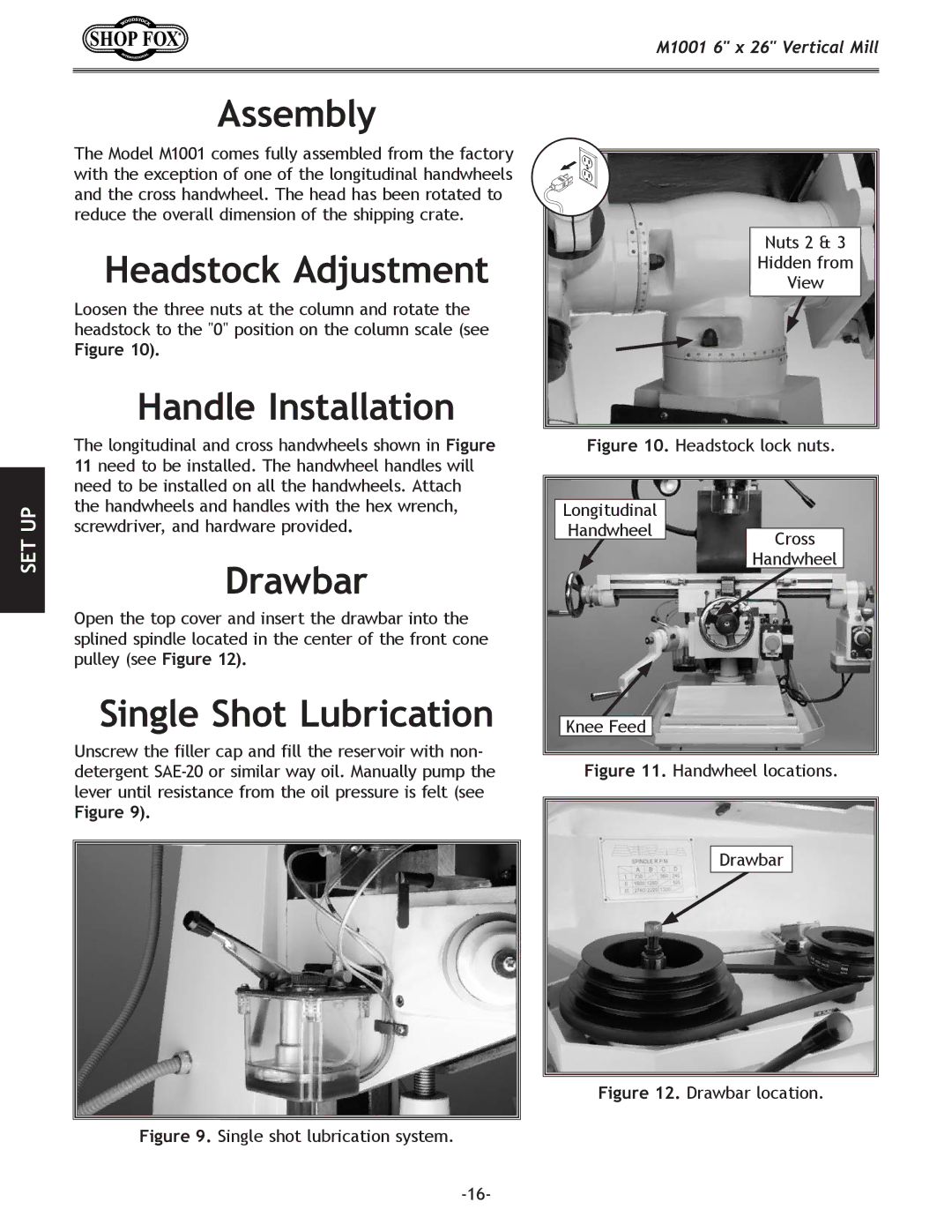

Loosen the three nuts at the column and rotate the headstock to the "0" position on the column scale (see

Figure 10).

Handle Installation

The longitudinal and cross handwheels shown in Figure 11 need to be installed. The handwheel handles will need to be installed on all the handwheels. Attach the handwheels and handles with the hex wrench, screwdriver, and hardware provided.

Drawbar

Open the top cover and insert the drawbar into the splined spindle located in the center of the front cone pulley (see Figure 12).

Single Shot Lubrication

Unscrew the filler cap and fill the reservoir with non- detergent

Figure 9).

Nuts 2 & 3

Hidden from

View

Figure 10. Headstock lock nuts.

Longitudinal

HandwheelCross

Handwheel