M1001 6" x 26" Vertical Mill

Installing Tools

To load a tool in the spindle, do these steps:

1.UNPLUG THE MILL!

2.Turn the mill OFF, allow it to come to a complete stop and unplug the mill.

3.Clean any debris from the spindle opening.

4.Insert the tool holder or a collet into the spindle.

5.Rotate the holder until the groove lines up with the key and the holder slides into the spindle.

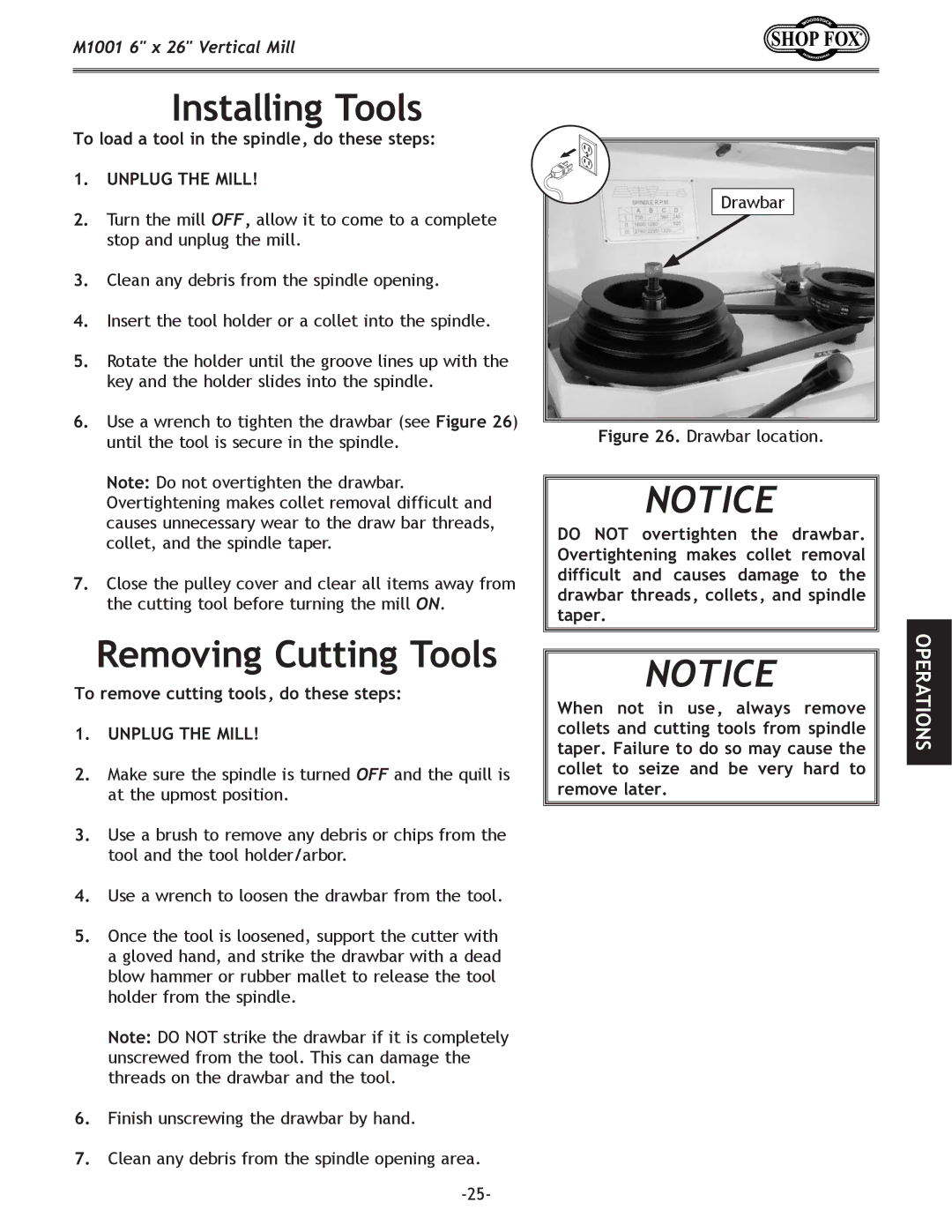

6.Use a wrench to tighten the drawbar (see Figure 26) until the tool is secure in the spindle.

Note: Do not overtighten the drawbar. Overtightening makes collet removal difficult and causes unnecessary wear to the draw bar threads, collet, and the spindle taper.

7.Close the pulley cover and clear all items away from the cutting tool before turning the mill ON.

Removing Cutting Tools

To remove cutting tools, do these steps:

1.UNPLUG THE MILL!

2.Make sure the spindle is turned OFF and the quill is at the upmost position.

3.Use a brush to remove any debris or chips from the tool and the tool holder/arbor.

4.Use a wrench to loosen the drawbar from the tool.

5.Once the tool is loosened, support the cutter with a gloved hand, and strike the drawbar with a dead blow hammer or rubber mallet to release the tool holder from the spindle.

Note: DO NOT strike the drawbar if it is completely unscrewed from the tool. This can damage the threads on the drawbar and the tool.

6.Finish unscrewing the drawbar by hand.

7.Clean any debris from the spindle opening area.

Drawbar

Figure 26. Drawbar location.

NOTICE

DO NOT overtighten the drawbar. Overtightening makes collet removal difficult and causes damage to the drawbar threads, collets, and spindle taper.

NOTICE

When not in use, always remove collets and cutting tools from spindle taper. Failure to do so may cause the collet to seize and be very hard to remove later.

OPERATIONS