M1036 Micro Mill

Depth Stop

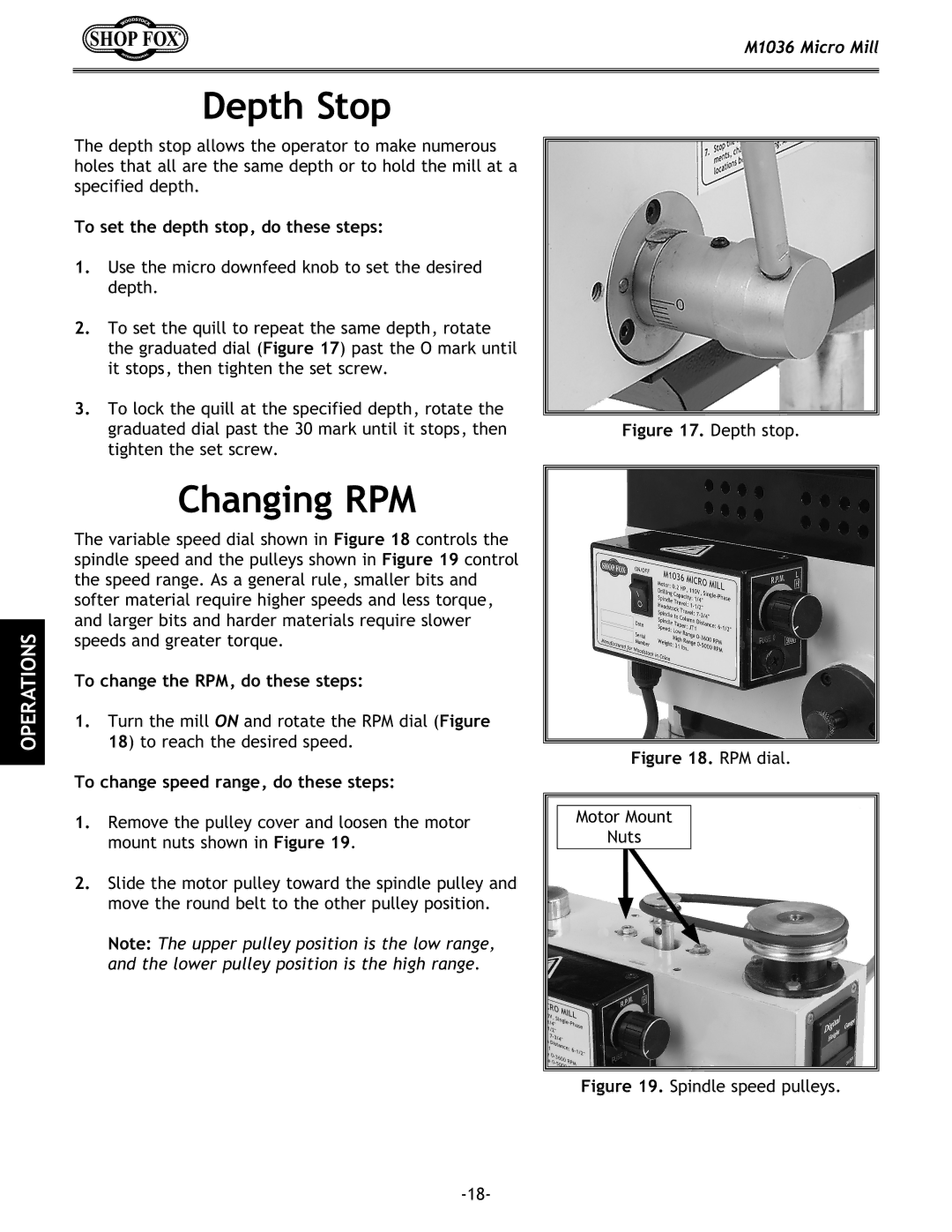

The depth stop allows the operator to make numerous holes that all are the same depth or to hold the mill at a specified depth.

To set the depth stop, do these steps:

1.Use the micro downfeed knob to set the desired depth.

2.To set the quill to repeat the same depth, rotate the graduated dial (Figure 17) past the O mark until it stops, then tighten the set screw.

3.To lock the quill at the specified depth, rotate the graduated dial past the 30 mark until it stops, then tighten the set screw.

Figure 17. Depth stop.

OPERATIONS

Changing RPM

The variable speed dial shown in Figure 18 controls the spindle speed and the pulleys shown in Figure 19 control the speed range. As a general rule, smaller bits and softer material require higher speeds and less torque, and larger bits and harder materials require slower speeds and greater torque.

To change the RPM, do these steps:

1.Turn the mill ON and rotate the RPM dial (Figure 18) to reach the desired speed.

To change speed range, do these steps:

1.Remove the pulley cover and loosen the motor mount nuts shown in Figure 19.

2.Slide the motor pulley toward the spindle pulley and move the round belt to the other pulley position.

Note: The upper pulley position is the low range, and the lower pulley position is the high range.

Figure 18. RPM dial.

Motor Mount

Nuts