Contents

Micro Mill

Page

Contents

Maintenance

Specifications

Introduction

Woodstock Technical Support

About Your New Micro Mill

Controls and Features

M1036 Controls and features

Safety

Standard Safety Instructions

Safety

Additional Safety Instructions for Micro Mills

Electrical

110V Operation

Extension Cords

Grounding

SET UP

Items Needed for Set Up

Unpacking

Bench Mounting Hardware Optional

Box 1 Contents Figure Qty

Box 2 Contents Figure Qty

Inventory

Box 1 Tools and Hardware Not Shown Qty

Machine Placement

Cleaning Machine

To install the headstock on the column, do these steps

Mounting to Workbench

Mounting Headstock to Column

To mount the mill to the workbench, do these steps

To install the compound slide table, do these steps

To install the vise, do these steps

Compound Slide Table

Vise

Test Run and Spindle Break-in

Operations

General

Table Travel

Graduated Dials

Backlash

Headstock Height

Downfeed Controls

Digital Height Gauge

To use the downfeed lever, do this step

To use the micro downfeed handwheel, do these steps

Depth Stop

Changing RPM

To set the depth stop, do these steps

To change the RPM, do these steps

To install a drill bit, do these steps

Drill Chuck

Drill Chuck Removal

To remove a drill bit, do these steps

To install the collet chuck, do these steps

To install the collet in the collet chuck, do these steps

Collets

Maintenance

Cleaning

Table & Base

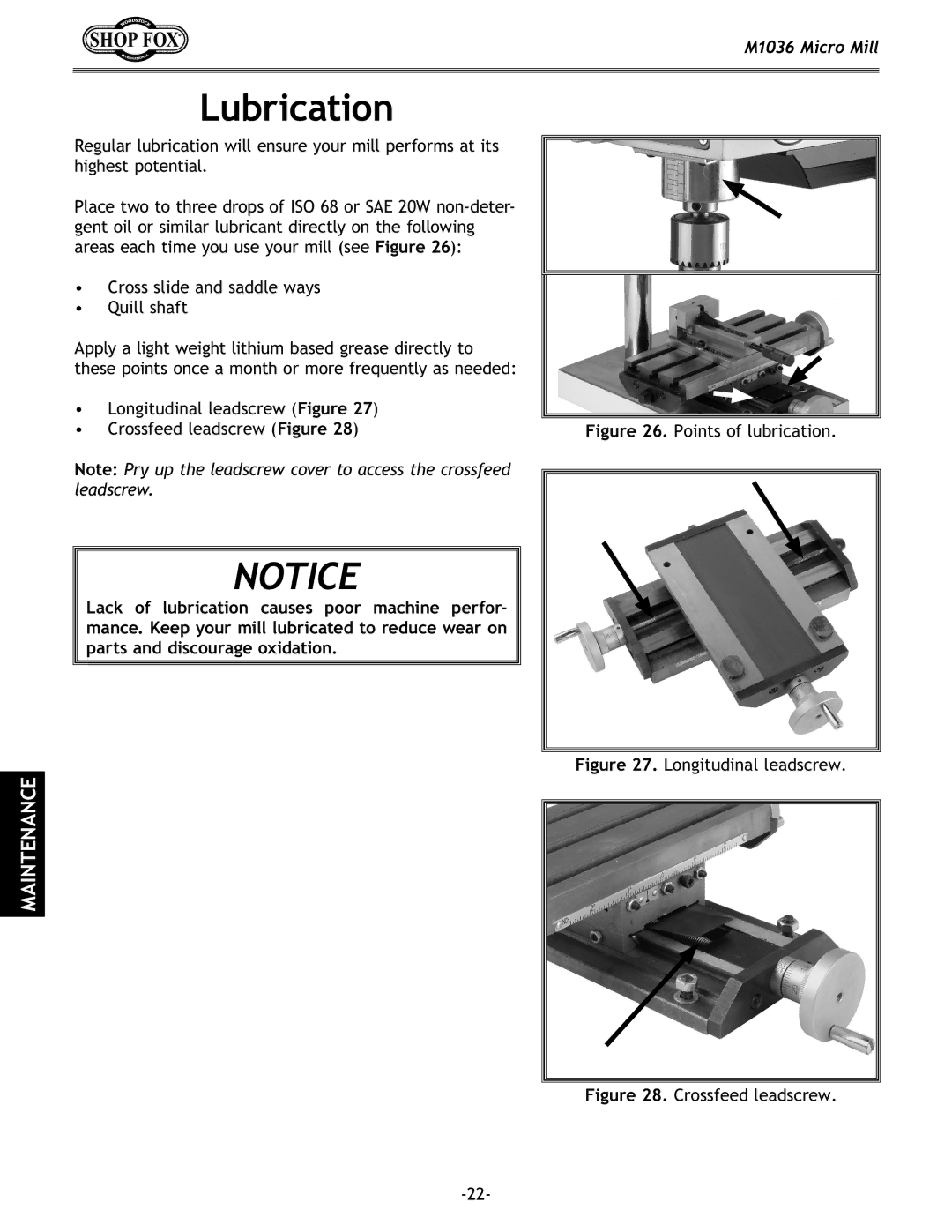

Lubrication

Cross slide and saddle ways Quill shaft

Service

To adjust the gibs, do these steps

Gibs

Fuse Replacement

Unscrew the cap from the motor housing see Figure

Replacing Motor Brushes

To replace the motor brushes, do these steps

Electrical Components

Troubleshooting

Symptom Possible Cause Corrective Action

Parts

Parts List

PART# Description

FLATWASHER24MM

Warranty

Warranty Registration

Comments

BOX BELLINGHAM, WA