M1036 Micro Mill

SERVICE

General

This section covers the most common service adjustments or procedures that may need to be made during the life of your machine.

If you require additional machine service not included in this section, please contact Woodstock International Technical Support at (360)

Gibs

The gibs are

When adjusting the gibs, the goal is to take out unneces- sary play in the table without causing the slides to bind. Loose gibs may cause poor finishes on the workpiece and may cause undue wear on the slide.

Each gib has multiple lock nuts and set screws that need to be adjusted. Make your adjustments equally and in small increments.

To adjust the gibs, do these steps:

1.UNPLUG THE MICRO MILL!

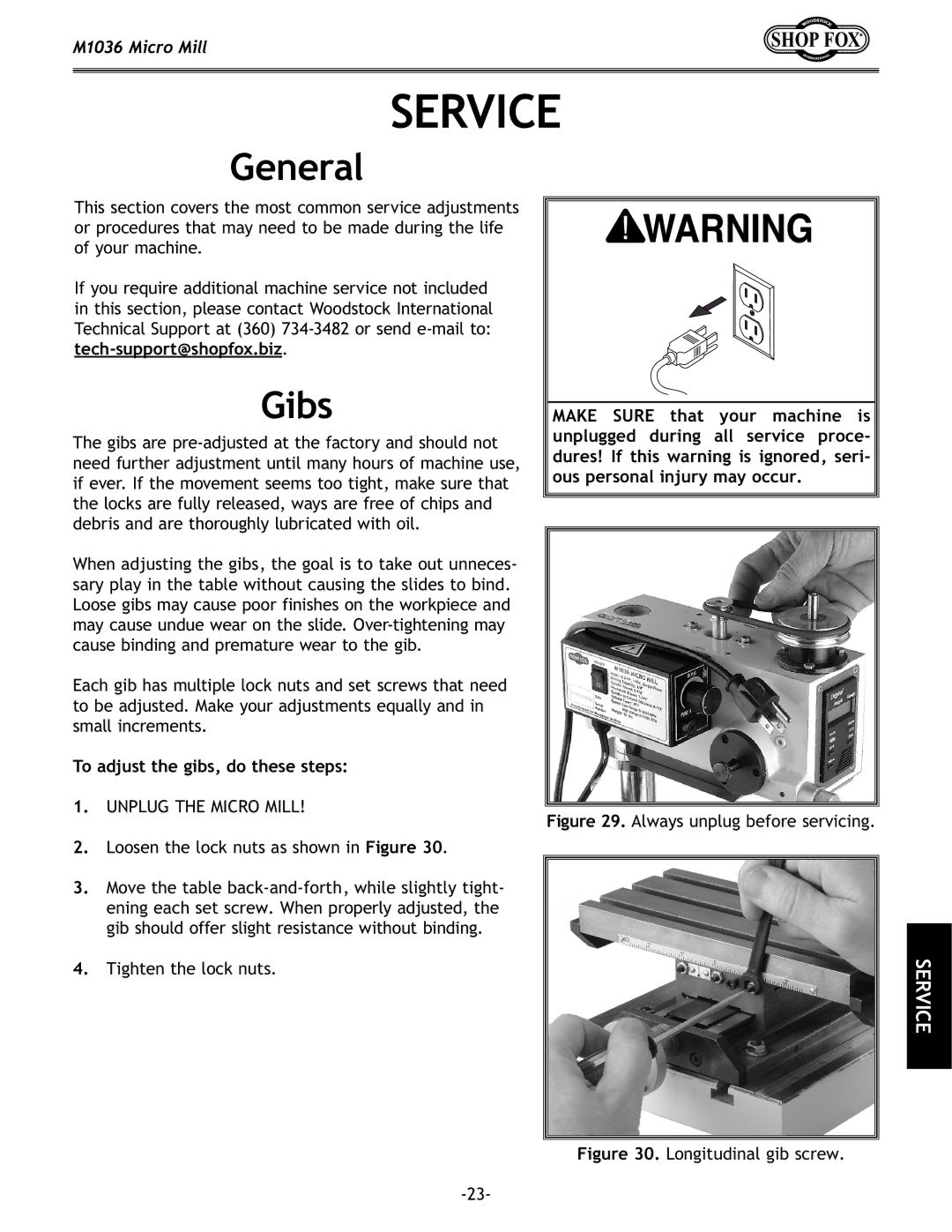

2.Loosen the lock nuts as shown in Figure 30.

3.Move the table

4.Tighten the lock nuts.

MAKE SURE that your machine is unplugged during all service proce- dures! If this warning is ignored, seri- ous personal injury may occur.

Figure 29. Always unplug before servicing.

SERVICE