SERVICE

|

| M1113 18" Wood/Metal Bandsaw | |

Wheel Alignment |

|

|

|

When wheels are aligned, or coplanar, the bandsaw cuts |

|

| Parallel, Not |

straighter, with much less vibration, heat, and blade wear |

| Coplanar | |

| Coplanar | ||

because the blade is automatically balanced on the wheel. |

|

| |

|

|

| |

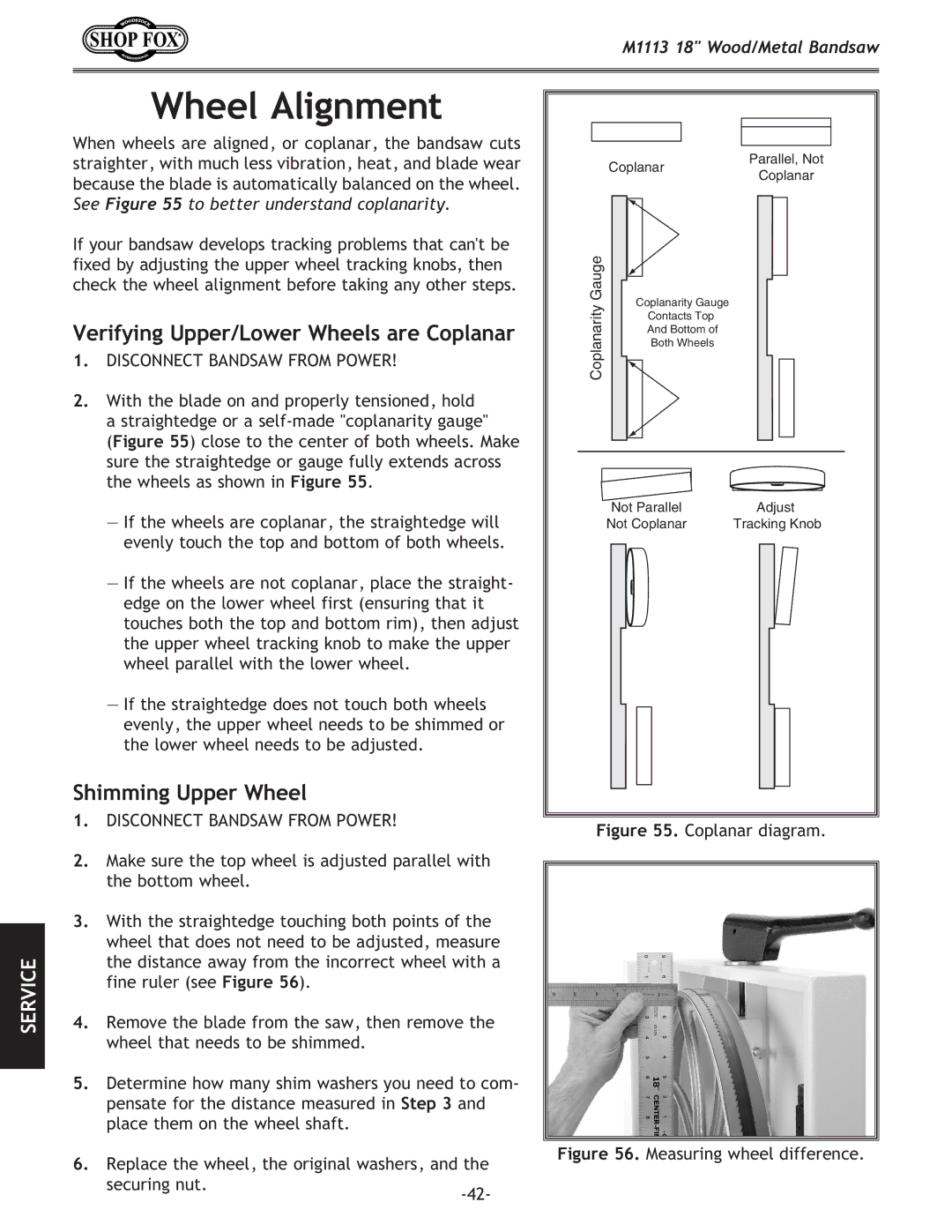

See Figure 55 to better understand coplanarity. |

|

|

|

If your bandsaw develops tracking problems that can't be | Gauge |

|

|

fixed by adjusting the upper wheel tracking knobs, then |

|

| |

check the wheel alignment before taking any other steps. |

|

| |

|

|

| |

| Coplanarity | Coplanarity Gauge |

|

Verifying Upper/Lower Wheels are Coplanar | Contacts Top |

| |

|

| ||

| Both Wheels |

| |

|

| And Bottom of |

|

1. DISCONNECT BANDSAW FROM POWER! |

|

|

|

2. With the blade on and properly tensioned, hold |

|

|

|

a straightedge or a |

|

|

|

(Figure 55) close to the center of both wheels. Make |

|

|

|

sure the straightedge or gauge fully extends across |

|

|

|

the wheels as shown in Figure 55. |

|

|

|

— If the wheels are coplanar, the straightedge will |

| Not Parallel | Adjust |

| Not Coplanar | Tracking Knob | |

evenly touch the top and bottom of both wheels. |

|

|

|

— If the wheels are not coplanar, place the straight- |

|

|

|

edge on the lower wheel first (ensuring that it |

|

|

|

touches both the top and bottom rim), then adjust |

|

|

|

the upper wheel tracking knob to make the upper |

|

|

|

wheel parallel with the lower wheel. |

|

|

|

— If the straightedge does not touch both wheels |

|

|

|

evenly, the upper wheel needs to be shimmed or |

|

|

|

the lower wheel needs to be adjusted. |

|

|

|

Shimming Upper Wheel |

|

|

|

1. DISCONNECT BANDSAW FROM POWER! | Figure 55. Coplanar diagram. | ||

| |||

2. Make sure the top wheel is adjusted parallel with |

|

|

|

the bottom wheel. |

|

|

|

3.With the straightedge touching both points of the wheel that does not need to be adjusted, measure the distance away from the incorrect wheel with a fine ruler (see Figure 56).

4.Remove the blade from the saw, then remove the wheel that needs to be shimmed.

5.Determine how many shim washers you need to com- pensate for the distance measured in Step 3 and place them on the wheel shaft.

6. | Replace the wheel, the original washers, and the | Figure 56. Measuring wheel difference. |

|

securing nut.