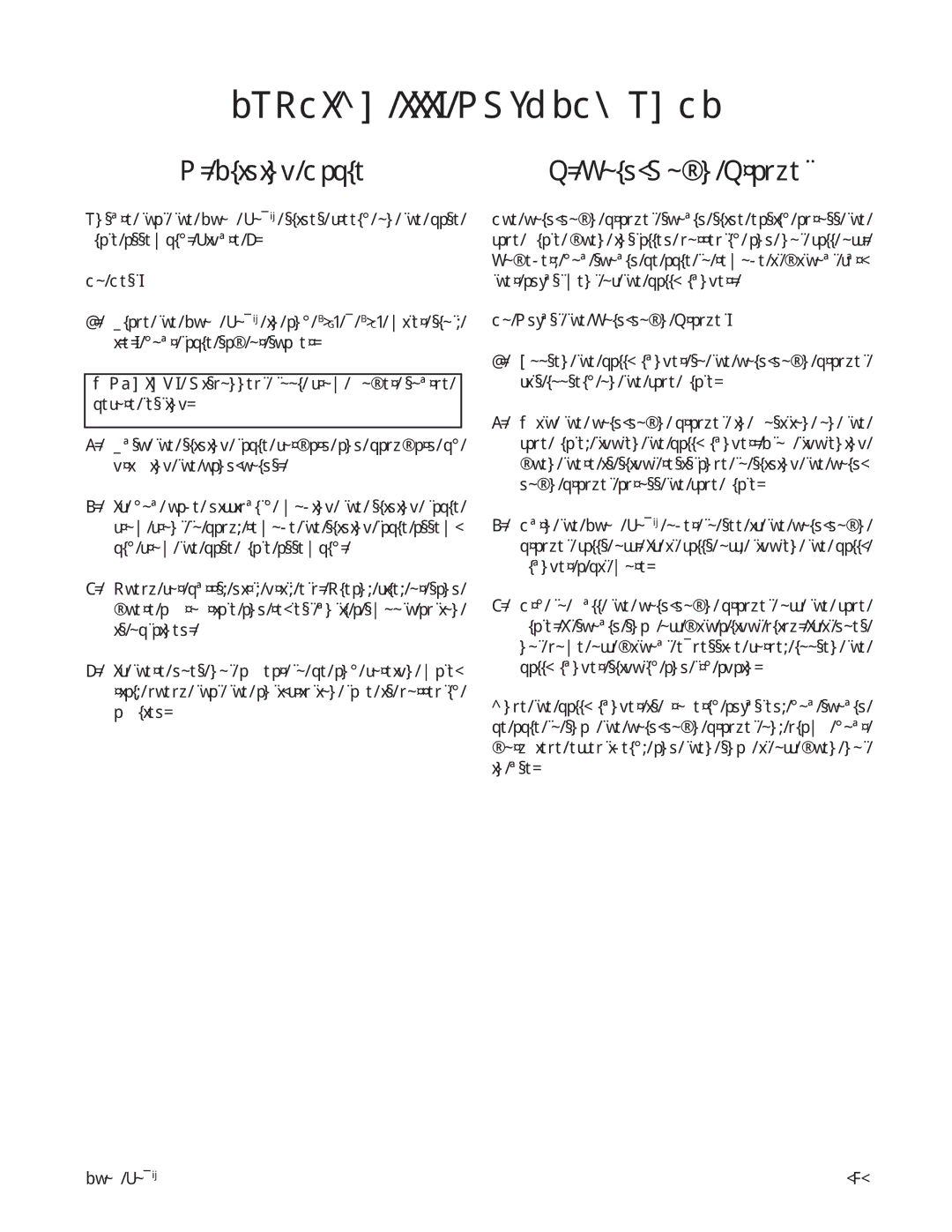

A. Sliding Table

Ensure that the Shop Fox® slides freely on the base plate assembly. Figure 5.

To Test:

1.Place the Shop Fox® in any 3/8" x 3/4" miter slot, i.e.: your table saw or shaper.

WARNING: Disconnect tool from power source before testing.

2.Push the sliding table forward and backward by gripping the hand-holds.

3.If you have difficulty moving the sliding table from front to back, remove the sliding table assem- bly from the base plate assembly.

4.Check for burrs, dirt, grit, etc. Clean, file, or sand where appropriate and re-test until a smooth action is obtained.

5.If there does not appear to be any foreign mate- rial, check that the anti-friction tape is correctly applied.

B. Hold-Down Bracket

The hold-down bracket should slide easily across the face plate when installed correctly and not fall off. However, you should be able to remove it without fur- ther adjustment of the ball-plunger.

To Adjust the Hold-down Bracket:

1.Loosen the ball-plunger so the hold-down bracket fits loosely on the face plate.

2.With the hold-down bracket in position on the face plate, tighten the ball-plunger. Stop tightening when there is slight resistance to sliding the hold- down bracket across the face plate.

3.Turn the Shop Fox® over to see if the hold-down bracket falls off. If it falls off, tighten the ball- plunger a bit more.

4.Try to pull the hold-down bracket off the face plate. It should snap off with a light click. If it does not come off without excessive force, loosen the ball-plunger slightly and try again.

Once the ball-plunger is properly adjusted, you should be able to snap the hold-down bracket on, clamp your workpiece effectively, and then snap it off when not in use.