SECTION IV: SET-UP

A. Planning | C. Horizontal Clamping |

Enough cannot be said about proper planning during any project. A job thoroughly planned is a job almost done. Go through the operational steps necessary to complete your project and determine which steps may benefit by using the Shop Fox®. It helps to number all your parts and pieces. We also recommend that you have plenty of scrap material on hand so that you can make periodic tests before cutting, machining, or sand- ing your actual workpiece.

Planning also includes making sure your shop is clean, that you have the necessary clearance for the stock you are processing, that there is enough lighting to see what you are doing, and that you have reviewed all of the safety rules concerning your project and the machines that will be put to use.

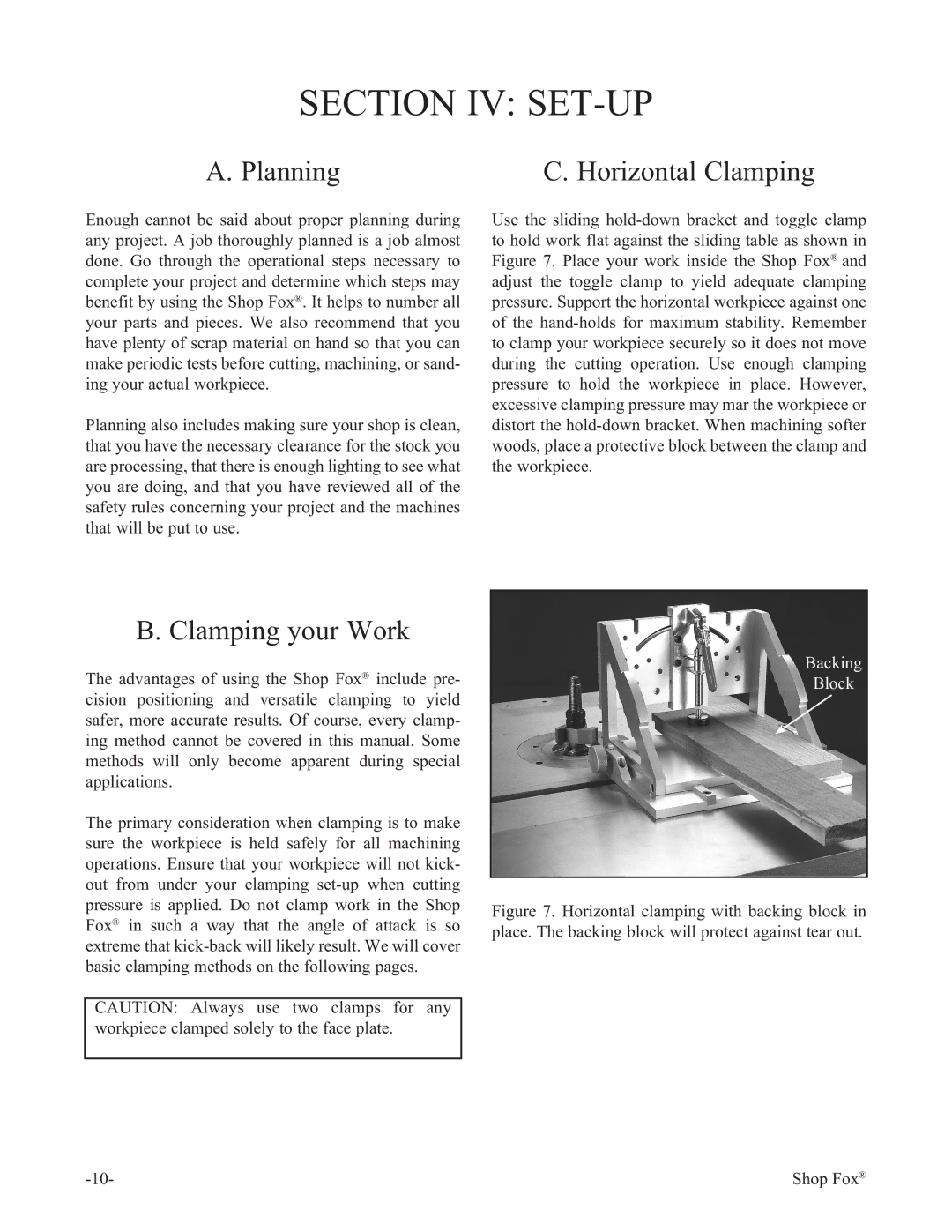

Use the sliding

B. Clamping your Work

The advantages of using the Shop Fox® include pre- cision positioning and versatile clamping to yield safer, more accurate results. Of course, every clamp- ing method cannot be covered in this manual. Some methods will only become apparent during special applications.

The primary consideration when clamping is to make sure the workpiece is held safely for all machining operations. Ensure that your workpiece will not kick- out from under your clamping

CAUTION: Always use two clamps for any workpiece clamped solely to the face plate.

Backing

Block

Figure 7. Horizontal clamping with backing block in place. The backing block will protect against tear out.

Shop Fox® |