E. Parallelism

Alignment of the miter bar parallel to the front edge of the base plate is important for optimum performance. Two methods of adjustment are described here.

Method 1:

1.Loosen the two (2) mounting screws that secure the miter bar to the base plate.

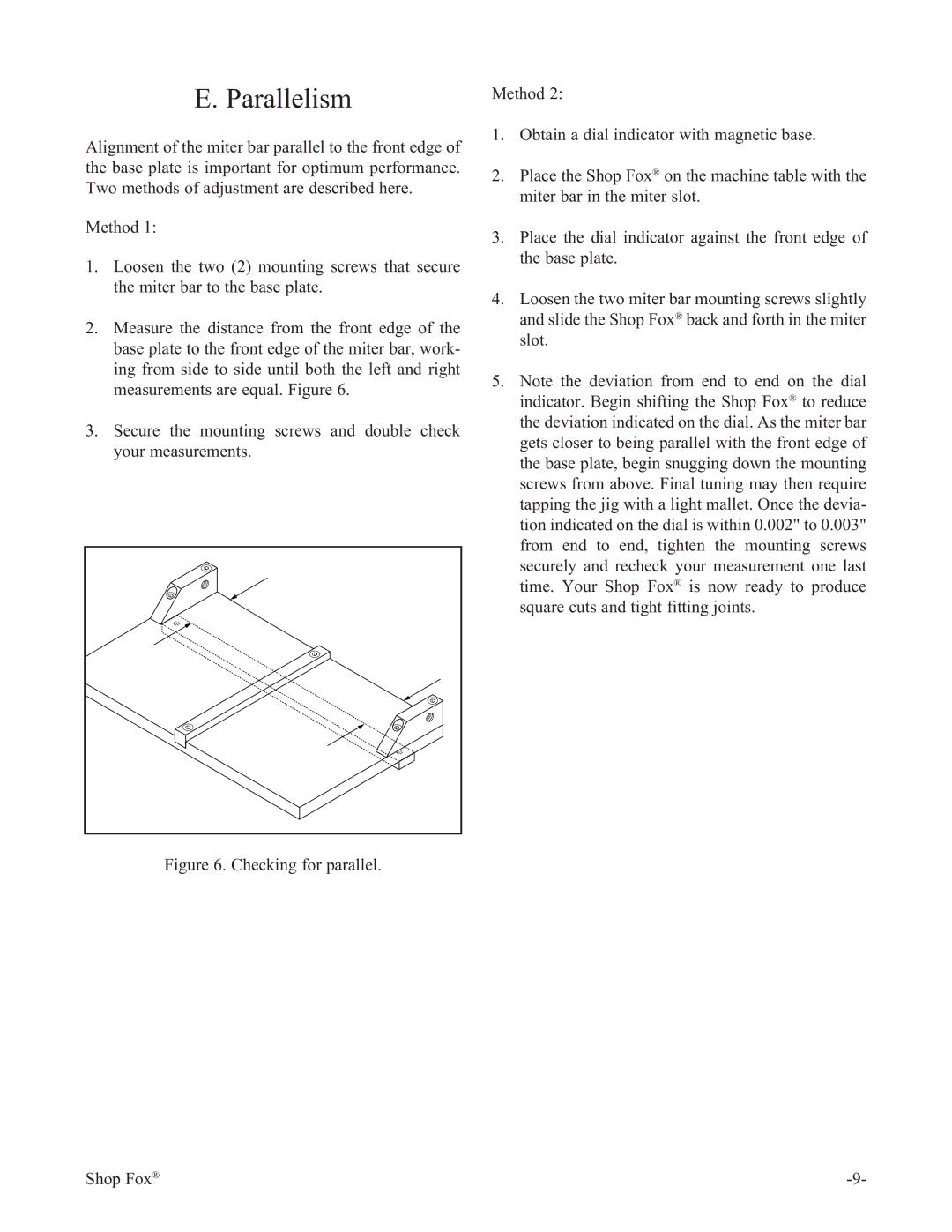

2.Measure the distance from the front edge of the base plate to the front edge of the miter bar, work- ing from side to side until both the left and right measurements are equal. Figure 6.

3.Secure the mounting screws and double check your measurements.

Figure 6. Checking for parallel.

Method 2:

1.Obtain a dial indicator with magnetic base.

2.Place the Shop Fox® on the machine table with the miter bar in the miter slot.

3.Place the dial indicator against the front edge of the base plate.

4.Loosen the two miter bar mounting screws slightly and slide the Shop Fox® back and forth in the miter slot.

5.Note the deviation from end to end on the dial indicator. Begin shifting the Shop Fox® to reduce the deviation indicated on the dial. As the miter bar gets closer to being parallel with the front edge of the base plate, begin snugging down the mounting screws from above. Final tuning may then require tapping the jig with a light mallet. Once the devia- tion indicated on the dial is within 0.002" to 0.003" from end to end, tighten the mounting screws securely and recheck your measurement one last time. Your Shop Fox® is now ready to produce square cuts and tight fitting joints.

Shop Fox® |