C. Vertical Work | D. Angled Work |

You can locate your workpiece in many positions on the face plate depending upon your requirements. When holding the stock vertically on the face plate, use the 90° angle bracket to support the work on the exit side. If you change cutter rotation, the 90° angle bracket must be moved to the opposite side of the face plate in order to support the work on the exit side. We also recommend placing a backing block between the angle bracket and the workpiece to back up the workpiece and reduce the risk of tear out. Always use a minimum of two clamps for vertical work.

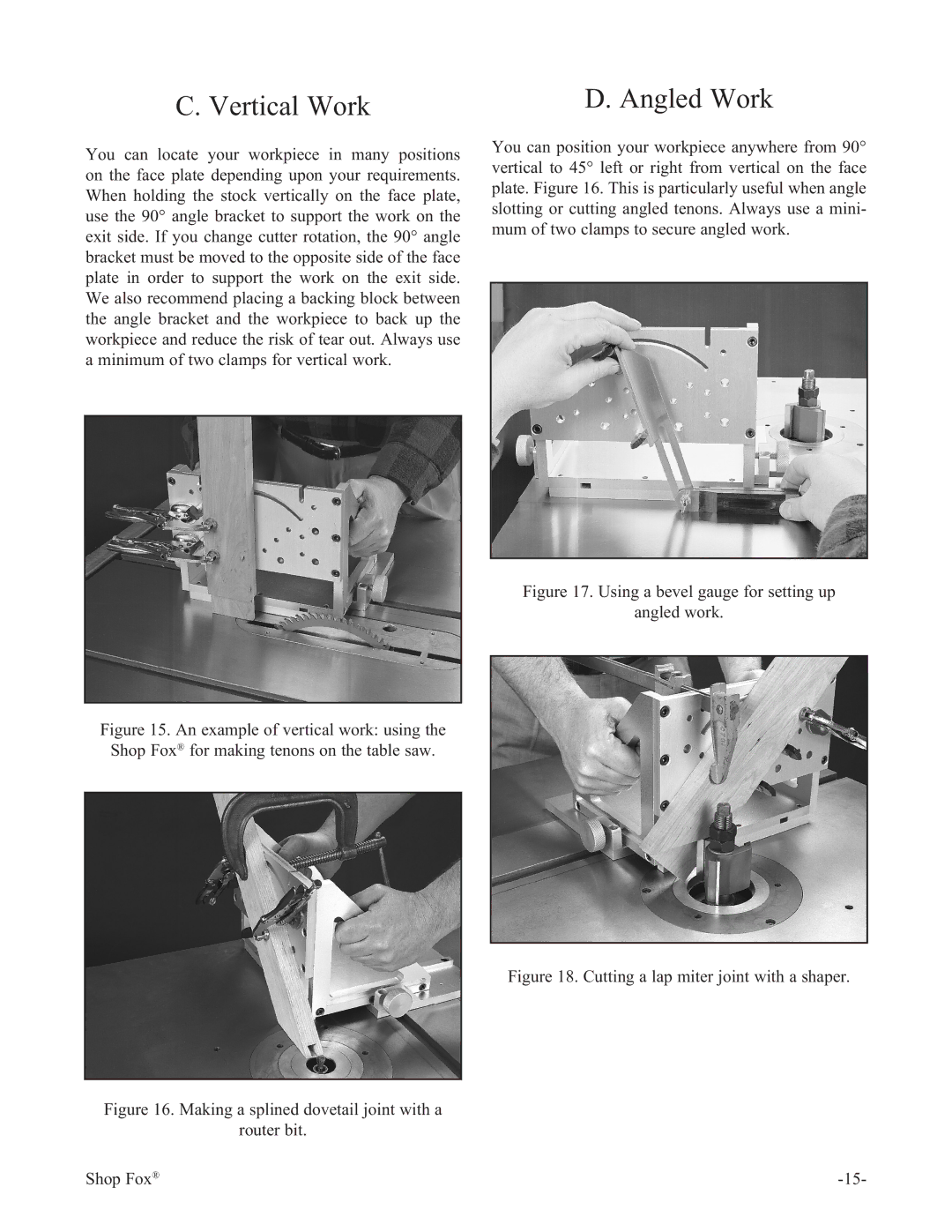

You can position your workpiece anywhere from 90° vertical to 45° left or right from vertical on the face plate. Figure 16. This is particularly useful when angle slotting or cutting angled tenons. Always use a mini- mum of two clamps to secure angled work.

Figure 15. An example of vertical work: using the Shop Fox® for making tenons on the table saw.

Figure 17. Using a bevel gauge for setting up

angled work.

Figure 18. Cutting a lap miter joint with a shaper.

Figure 16. Making a splined dovetail joint with a

router bit.

Shop Fox® |