D. Vertical Clamping | E. Other Clamping Methods |

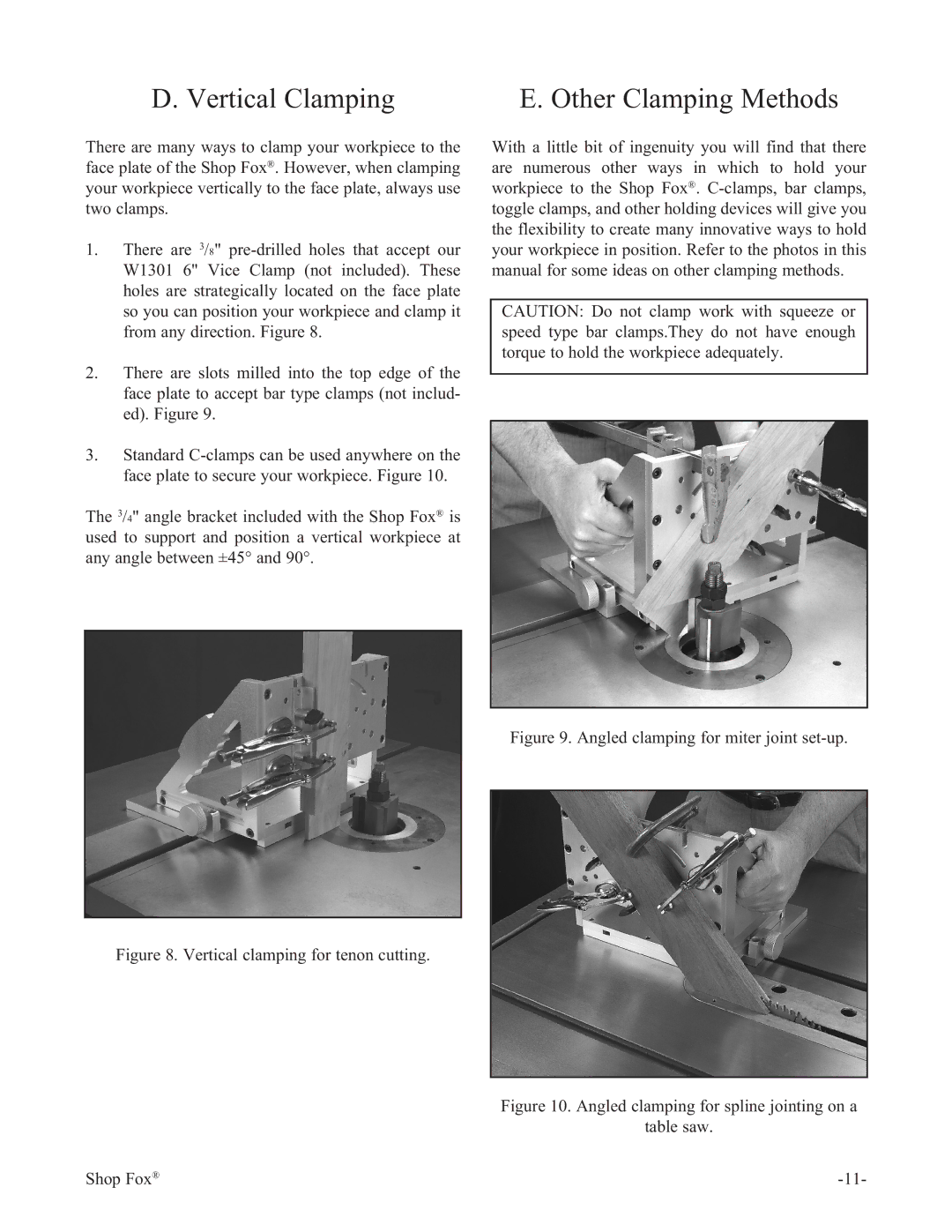

There are many ways to clamp your workpiece to the face plate of the Shop Fox®. However, when clamping your workpiece vertically to the face plate, always use two clamps.

1.There are 3/8"

2.There are slots milled into the top edge of the face plate to accept bar type clamps (not includ- ed). Figure 9.

3.Standard

The 3/4" angle bracket included with the Shop Fox® is used to support and position a vertical workpiece at any angle between ±45° and 90°.

Figure 8. Vertical clamping for tenon cutting.

With a little bit of ingenuity you will find that there are numerous other ways in which to hold your workpiece to the Shop Fox®. C-clamps, bar clamps, toggle clamps, and other holding devices will give you the flexibility to create many innovative ways to hold your workpiece in position. Refer to the photos in this manual for some ideas on other clamping methods.

CAUTION: Do not clamp work with squeeze or speed type bar clamps.They do not have enough torque to hold the workpiece adequately.

Figure 9. Angled clamping for miter joint set-up.

Figure 10. Angled clamping for spline jointing on a

table saw.

Shop Fox® |