Blade Guides Cont.

The upper and lower guide blocks reduce

To adjust the guide blocks:

1.Find the thumbscrews that allow the guide- block pair to slide back and forth.

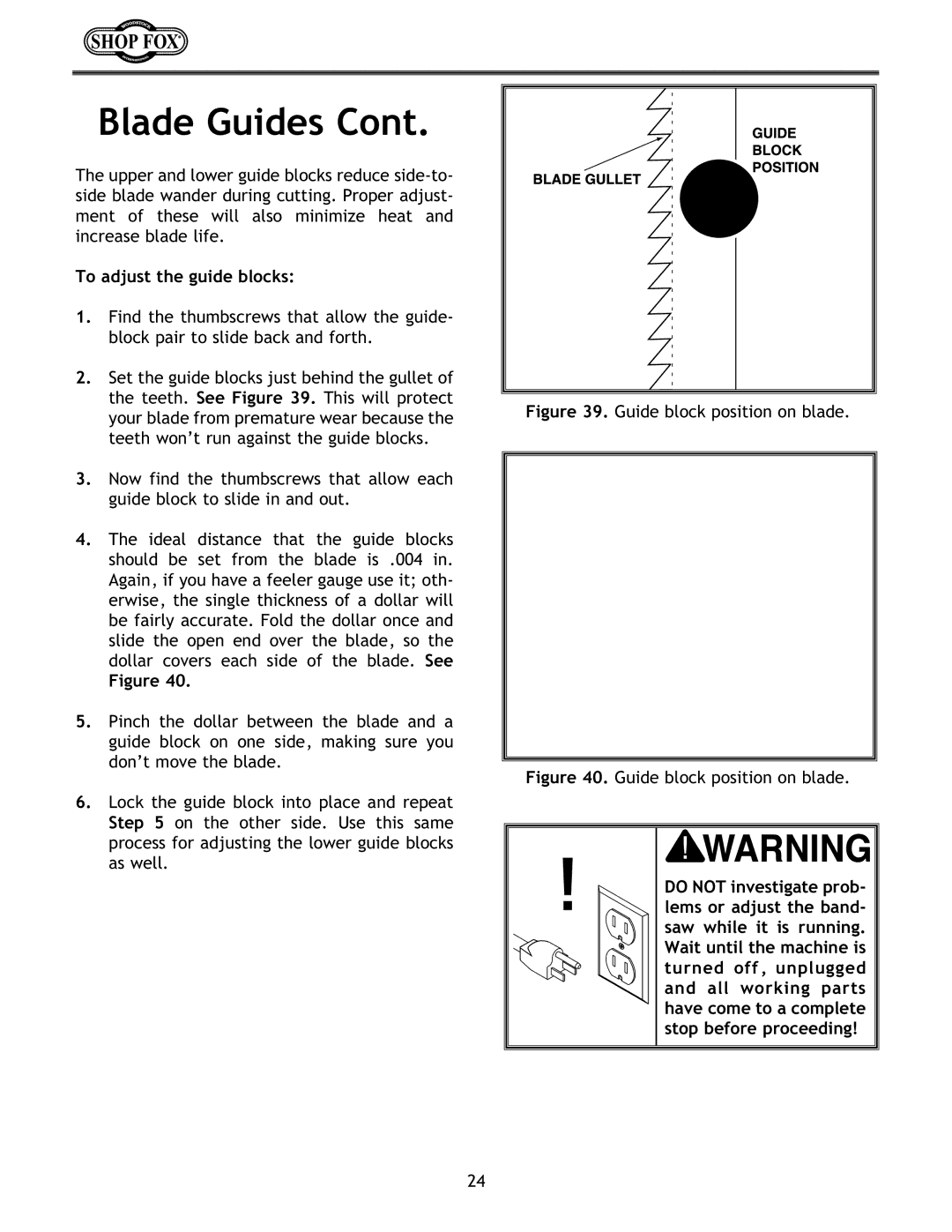

2.Set the guide blocks just behind the gullet of the teeth. See Figure 39. This will protect your blade from premature wear because the teeth won’t run against the guide blocks.

3.Now find the thumbscrews that allow each guide block to slide in and out.

4.The ideal distance that the guide blocks should be set from the blade is .004 in. Again, if you have a feeler gauge use it; oth- erwise, the single thickness of a dollar will be fairly accurate. Fold the dollar once and slide the open end over the blade, so the dollar covers each side of the blade. See

Figure 40.

5.Pinch the dollar between the blade and a guide block on one side, making sure you don’t move the blade.

6.Lock the guide block into place and repeat Step 5 on the other side. Use this same process for adjusting the lower guide blocks as well.

Figure 39. Guide block position on blade.

Figure 40. Guide block position on blade.

DO NOT investigate prob- lems or adjust the band- saw while it is running. Wait until the machine is turned off, unplugged and all working parts have come to a complete stop before proceeding!

24