Operation

Requirements

•Never allow hands or push blocks to come within 4" of the cutterhead while it is mov- ing.

•Carefully inspect boards before jointing. Defects such as twisting, knots, or cracks could cause the workpiece to break apart.

•Only use clean boards. Remove all dirt, nails, staples, imbedded gravel, etc. from boards before jointing. Dirt and debris can damage the cutting edge of the cutterhead blades, resulting in unsatisfactory results.

•DO NOT joint

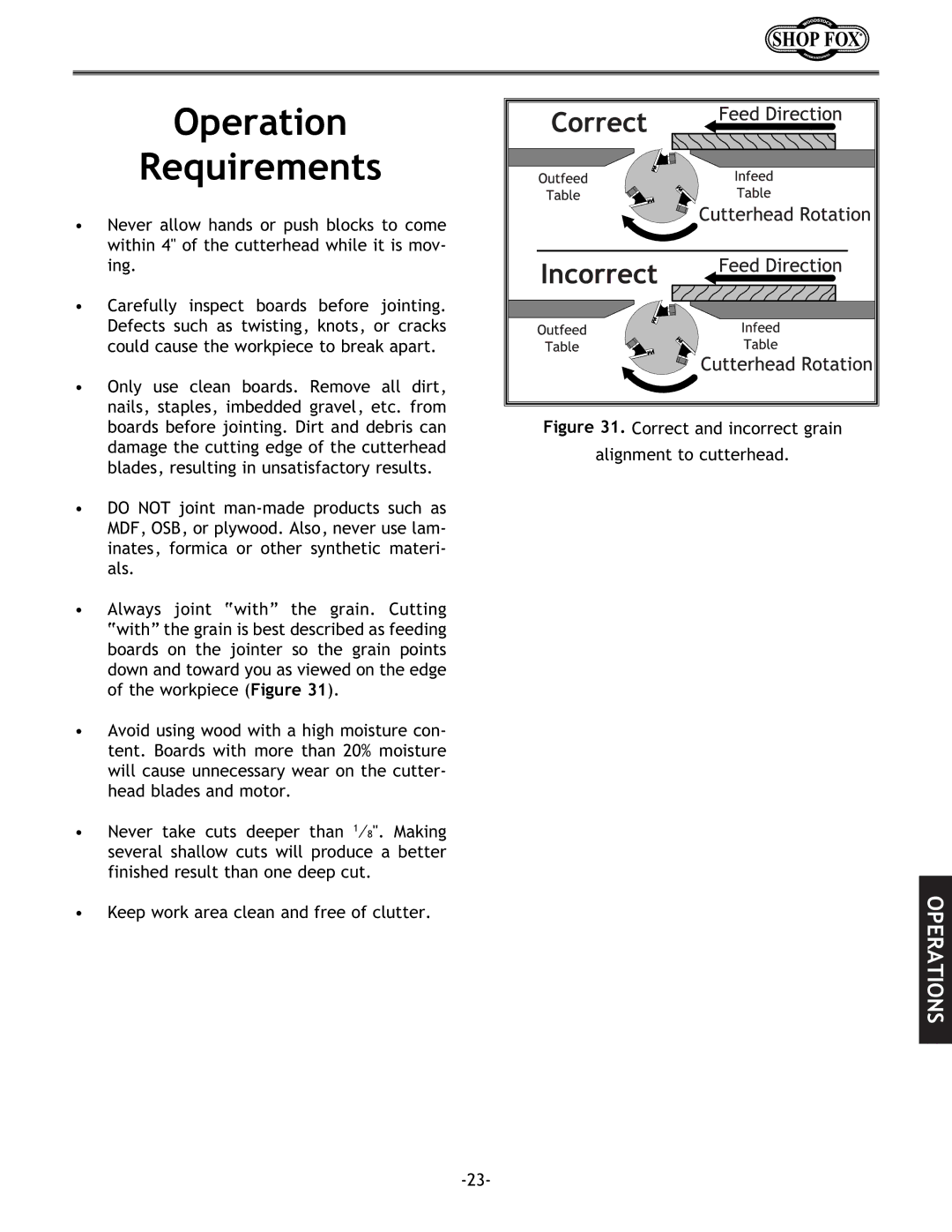

•Always joint “with” the grain. Cutting “with” the grain is best described as feeding boards on the jointer so the grain points down and toward you as viewed on the edge of the workpiece (Figure 31).

•Avoid using wood with a high moisture con- tent. Boards with more than 20% moisture will cause unnecessary wear on the cutter- head blades and motor.

•Never take cuts deeper than 1⁄8". Making several shallow cuts will produce a better finished result than one deep cut.

•Keep work area clean and free of clutter.