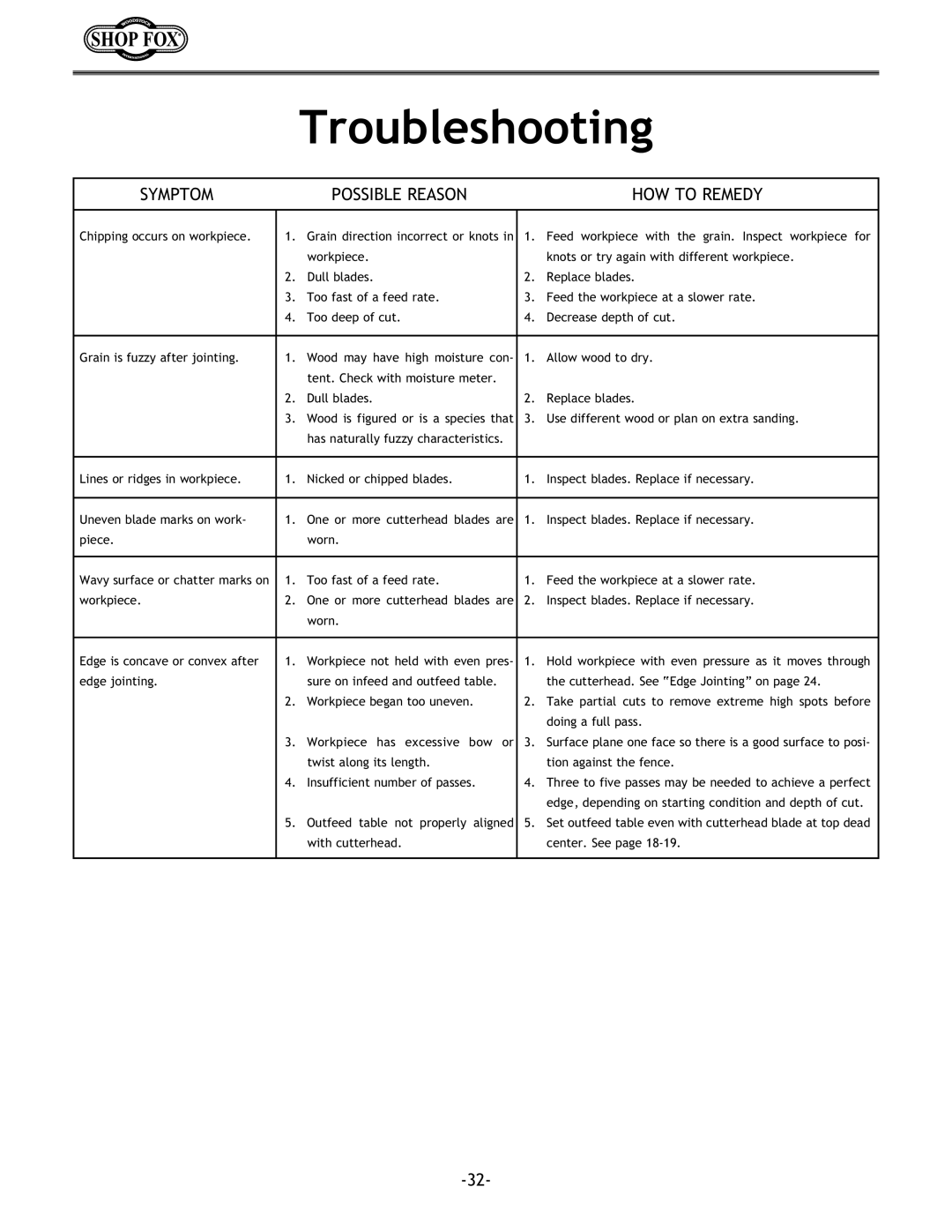

Troubleshooting

|

|

|

|

|

|

|

|

|

| SYMPTOM |

|

| POSSIBLE REASON |

|

| HOW TO REMEDY |

|

|

|

|

|

|

|

|

|

|

| Chipping occurs on workpiece. |

| 1. | Grain direction incorrect or knots in |

| 1. | Feed workpiece with the grain. Inspect workpiece for |

|

|

|

|

| workpiece. |

|

| knots or try again with different workpiece. |

|

|

|

| 2. | Dull blades. |

| 2. | Replace blades. |

|

|

|

| 3. | Too fast of a feed rate. |

| 3. | Feed the workpiece at a slower rate. |

|

|

|

| 4. | Too deep of cut. |

| 4. | Decrease depth of cut. |

|

|

|

|

|

|

|

|

|

|

| Grain is fuzzy after jointing. |

| 1. | Wood may have high moisture con- |

| 1. | Allow wood to dry. |

|

|

|

|

| tent. Check with moisture meter. |

|

|

|

|

|

|

| 2. | Dull blades. |

| 2. | Replace blades. |

|

|

|

| 3. | Wood is figured or is a species that |

| 3. | Use different wood or plan on extra sanding. |

|

|

|

|

| has naturally fuzzy characteristics. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Lines or ridges in workpiece. |

| 1. | Nicked or chipped blades. |

| 1. | Inspect blades. Replace if necessary. |

|

|

|

|

|

|

|

|

|

|

| Uneven blade marks on work- |

| 1. | One or more cutterhead blades are |

| 1. | Inspect blades. Replace if necessary. |

|

| piece. |

|

| worn. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Wavy surface or chatter marks on |

| 1. | Too fast of a feed rate. |

| 1. | Feed the workpiece at a slower rate. |

|

| workpiece. |

| 2. | One or more cutterhead blades are |

| 2. | Inspect blades. Replace if necessary. |

|

|

|

|

| worn. |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Edge is concave or convex after |

| 1. | Workpiece not held with even pres- |

| 1. | Hold workpiece with even pressure as it moves through |

|

| edge jointing. |

|

| sure on infeed and outfeed table. |

|

| the cutterhead. See “Edge Jointing” on page 24. |

|

|

|

| 2. | Workpiece began too uneven. |

| 2. | Take partial cuts to remove extreme high spots before |

|

|

|

|

|

|

|

| doing a full pass. |

|

|

|

| 3. | Workpiece has excessive bow or |

| 3. | Surface plane one face so there is a good surface to posi- |

|

|

|

|

| twist along its length. |

|

| tion against the fence. |

|

|

|

| 4. | Insufficient number of passes. |

| 4. | Three to five passes may be needed to achieve a perfect |

|

|

|

|

|

|

|

| edge, depending on starting condition and depth of cut. |

|

|

|

| 5. | Outfeed table not properly aligned |

| 5. | Set outfeed table even with cutterhead blade at top dead |

|

|

|

|

| with cutterhead. |

|

| center. See page |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|