ADJUSTMENTS

V-Belt Tension

The sanding motor

KEEP the sanding drum drive belts correctly adjusted. If the belts are loose, and the emergency stop is engaged, the sanding drum pulley will slip and not immediately stop in the event of an emergency!

To tension the V-belts, do these steps:

1.

2.Remove the lower cover(s) on the sander (right cover for sanding belt motor, left cover for the conveyor height motor).

3.Turn both nuts clockwise to tighten the V- belts, or turn both nuts counterclockwise to loosen the

4.The

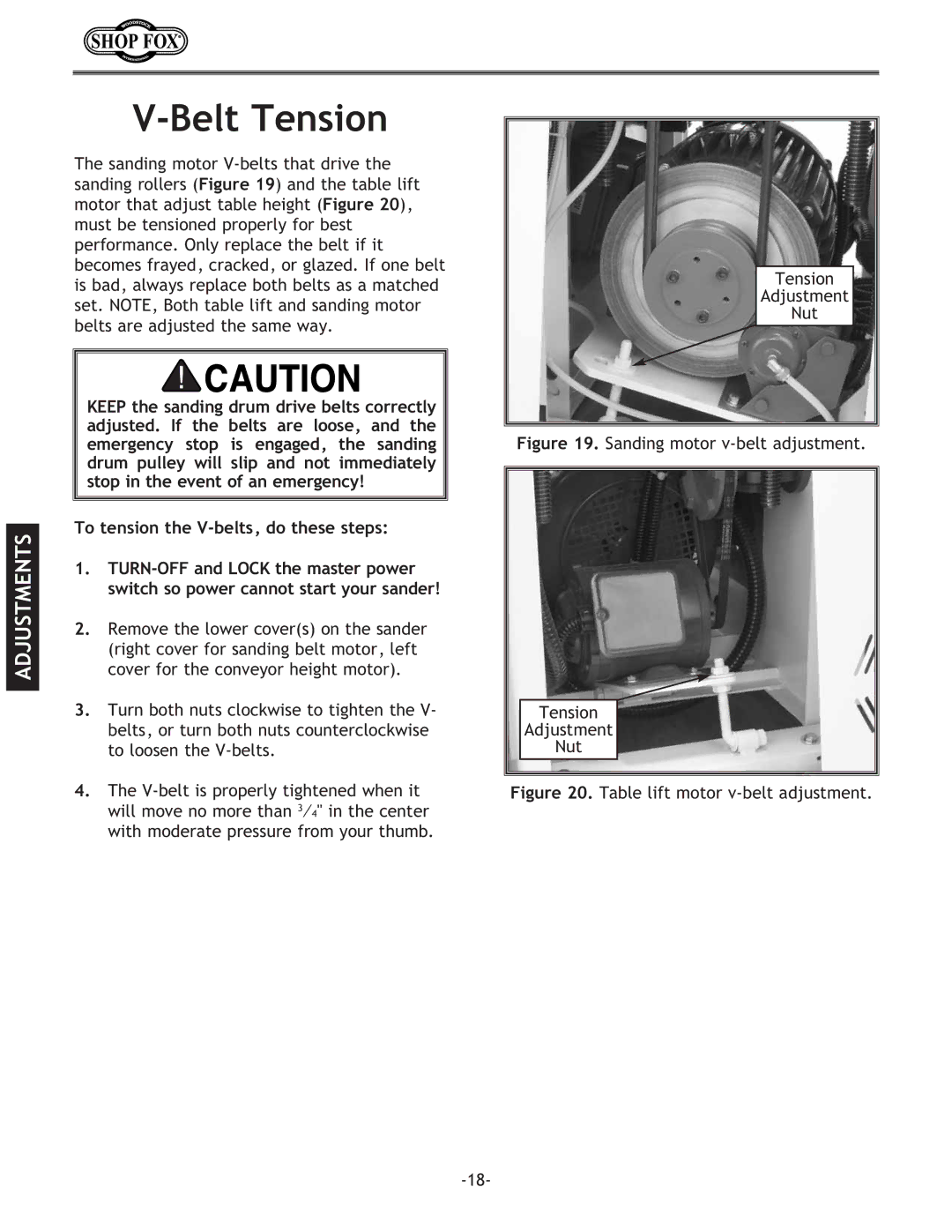

Tension

Adjustment

Nut