ADJUSTMENTS

Table Stop Switches

The table stop switches prevent the table lift motor from running the table into the sanding drum and bottoming out the table lift mechanism at the end of the jack screws. Periodically adjust the table stop switches.

To adjust table stop switches, do these steps:

1.Apply air to the sander and tension the sanding belt.

2.Push the down arrow key and lower the table until you achieve 6 inches between the sanding drum and the conveyor table surface. See Figure 22.

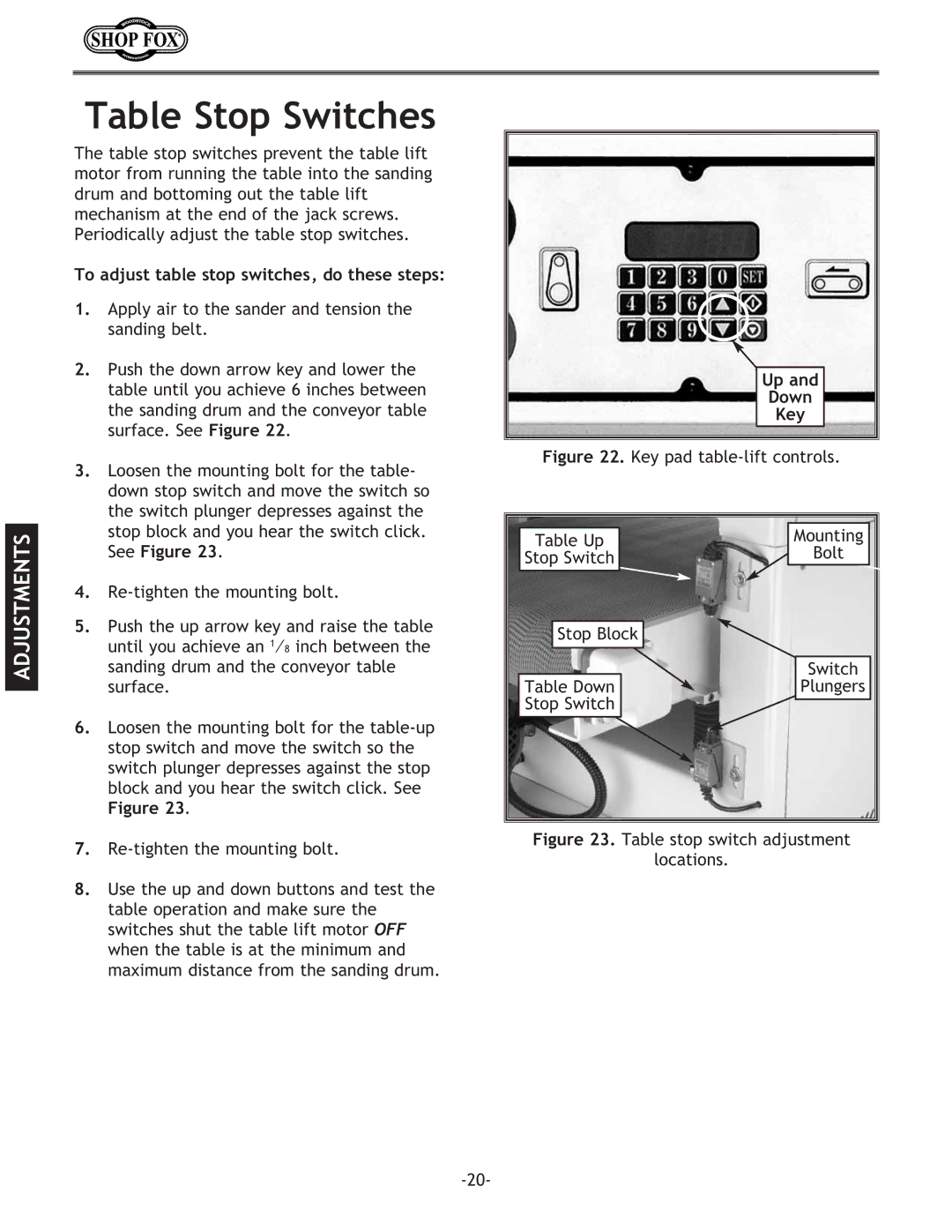

3.Loosen the mounting bolt for the table- down stop switch and move the switch so the switch plunger depresses against the stop block and you hear the switch click. See Figure 23.

4.

5.Push the up arrow key and raise the table until you achieve an 1⁄8 inch between the sanding drum and the conveyor table surface.

6.Loosen the mounting bolt for the

Figure 23.

7.

8.Use the up and down buttons and test the

table operation and make sure the switches shut the table lift motor OFF when the table is at the minimum and maximum distance from the sanding drum.

Up and

Down

Key

Figure 22. Key pad table-lift controls.

Table Up | Mounting |

Stop Switch | Bolt |

Stop Block |

|

| Switch |

Table Down | Plungers |

Stop Switch |

|