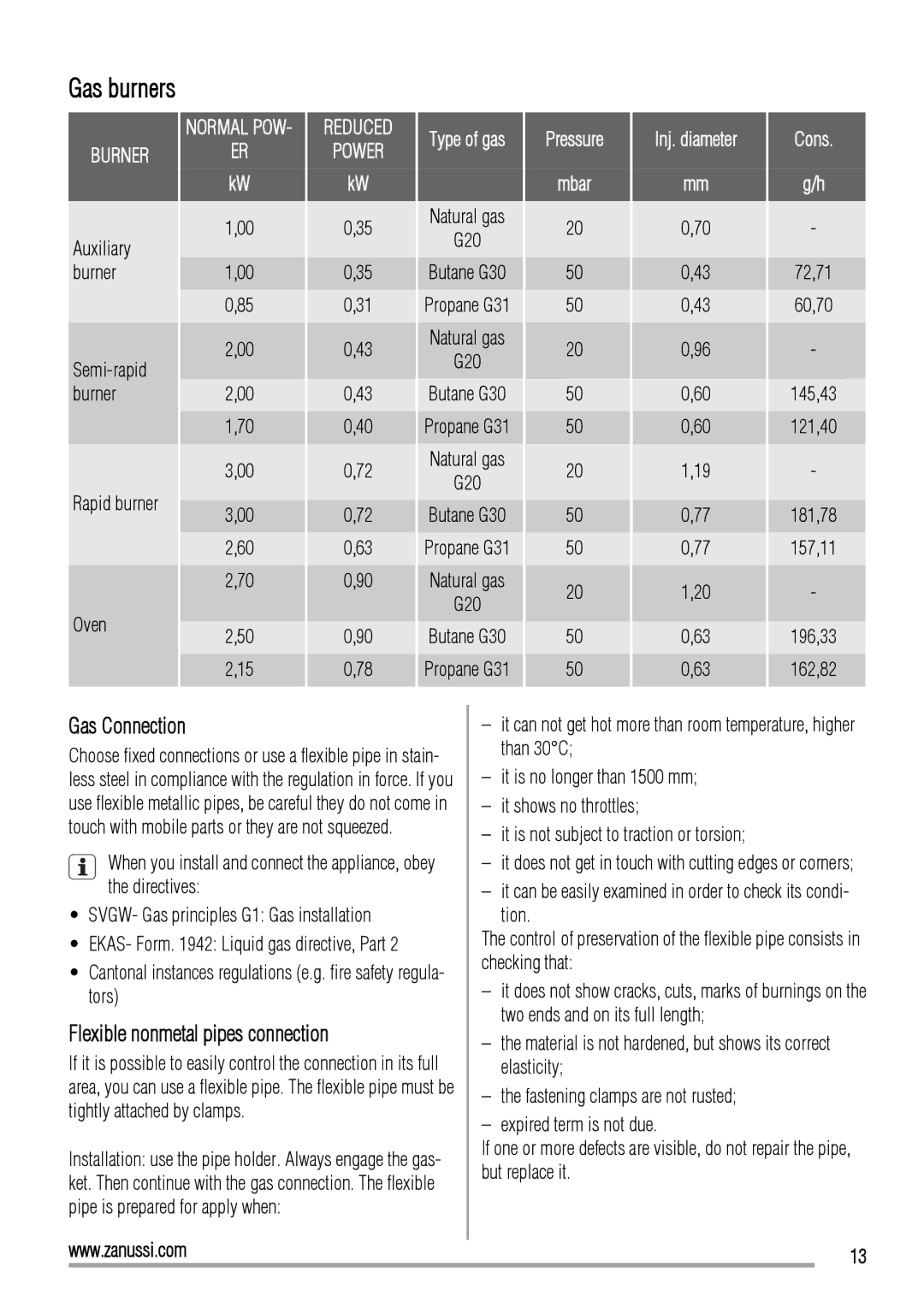

Gas burners

BURNER

Auxiliary burner

Rapid burner

Oven

NORMAL POW-

ER

kW

1,00

1,00

0,85

2,00

2,00

1,70

3,00

3,00

2,60

2,70

2,50

2,15

REDUCED

POWER

kW

0,35

0,35

0,31

0,43

0,43

0,40

0,72

0,72

0,63

0,90

0,90

0,78

Type of gas

Natural gas

G20

Butane G30

Propane G31

Natural gas

G20

Butane G30

Propane G31

Natural gas

G20

Butane G30

Propane G31

Natural gas

G20

Butane G30

Propane G31

Pressure

mbar

20

50

50

20

50

50

20

50

50

20

50

50

Inj. diameter

mm

0,70

0,43

0,43

0,96

0,60

0,60

1,19

0,77

0,77

1,20

0,63

0,63

Cons.

g/h

-

72,71

60,70

-

145,43

121,40

-

181,78

157,11

-

196,33

162,82

Gas Connection

Choose fixed connections or use a flexible pipe in stain- less steel in compliance with the regulation in force. If you use flexible metallic pipes, be careful they do not come in touch with mobile parts or they are not squeezed.

When you install and connect the appliance, obey the directives:

•SVGW- Gas principles G1: Gas installation

•EKAS- Form. 1942: Liquid gas directive, Part 2

•Cantonal instances regulations (e.g. fire safety regula- tors)

Flexible nonmetal pipes connection

If it is possible to easily control the connection in its full area, you can use a flexible pipe. The flexible pipe must be tightly attached by clamps.

Installation: use the pipe holder. Always engage the gas- ket. Then continue with the gas connection. The flexible pipe is prepared for apply when:

www.zanussi.com

–it can not get hot more than room temperature, higher than 30°C;

–it is no longer than 1500 mm;

–it shows no throttles;

–it is not subject to traction or torsion;

–it does not get in touch with cutting edges or corners;

–it can be easily examined in order to check its condi- tion.

The control of preservation of the flexible pipe consists in checking that:

–it does not show cracks, cuts, marks of burnings on the two ends and on its full length;

–the material is not hardened, but shows its correct elasticity;

–the fastening clamps are not rusted;

–expired term is not due.

If one or more defects are visible, do not repair the pipe, but replace it.

13