MA1

(1)

MA2

MA3

.025 in

0.655mm

MA4

English

9. Maintenance

![]()

![]() WARNING

WARNING

•Make sure that the engine has stopped and is cool before performing any service to the machine. Contact with moving cutting head or hot muffler may result in a personal injury.

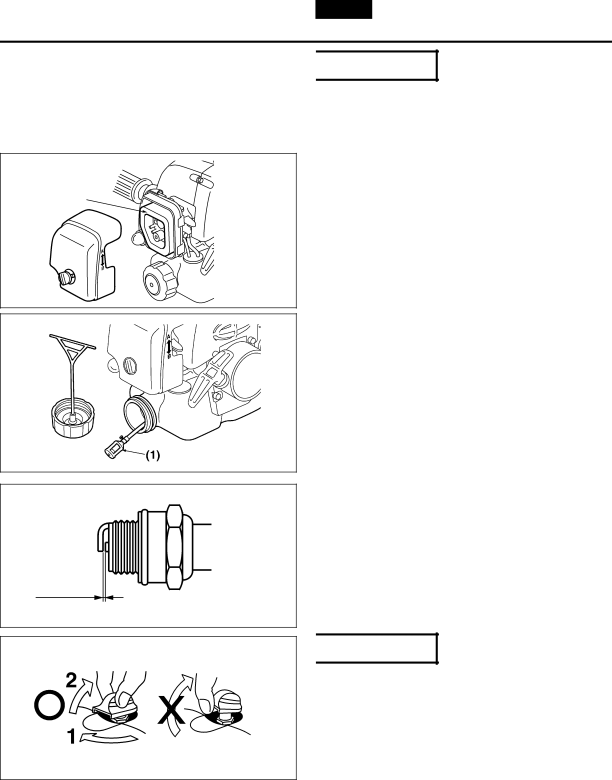

■AIR FILTER

•The air filter, if clogged, will reduce the engine performance. Check and clean the filter element in warm, soapy water as required. Dry completely before installing. If the element is broken or shrunk, replace with a new one. (MA1)

(1) air filter

■FUEL FILTER

•When the engine runs short of fuel supply, check the fuel cap and the fuel filter for blockage. (MA2)

(1) fuel filter

■SPARK PLUG

•Starting failure and

•When you take off the spark plug, twist (1) and pull off the cap (2). (MA4)

•REPLACEMENT PLUG IS A NGK BPMR7A.

![]()

![]() IMPORTANT

IMPORTANT

•Note that using any spark plug other than those designated may result in the engine failing to operate properly or in the engine becoming overheated and damaged.

•To install the spark plug, first turn the plug until it is finger tight, then tighten it a quarter turn more with a socket wrench.

TIGHTENING TORQUE:

87~104

(9.8~11.8 N.m.)

36