65 Series Rotary Tiller

SERVICE AND MAINTENANCE

SERVICE

Follow Maintenance Safety Instructions as outlined in Maintenance Safety.

FLUIDS AND LUBRICANTS

1.Hydraulic Oil:

Use standard hydraulic oil for all operating conditions.

2.Gear Box Oil:

Use an SAE 85W90 gear oil for all operating conditions. Gear Box Capacity: 1 U.S. quart (0.85 liter)

3.Chain Case Grease:

Use a multi purpose grease for all operating conditions. If chain case is removed, refill with 800 grams of grease.

4.Storing Lubricants:

Your machine can operate at top efficiency only if clean lubricants are used. Use clean containers to handle all lubricants. Store them in an area protected from dust, moisture and other contaminants.

GREASING

Use a Maintenance Checklist to keep a record of all scheduled maintenance.

1.Use a

2.Wipe grease fitting with a clean cloth before greasing, to avoid injecting dirt and grit.

3.Replace and repair broken fittings immediately.

4.If fittings will not take grease, remove and clean thoroughly. Also clean lubricant passageway. Replace fitting if necessary.

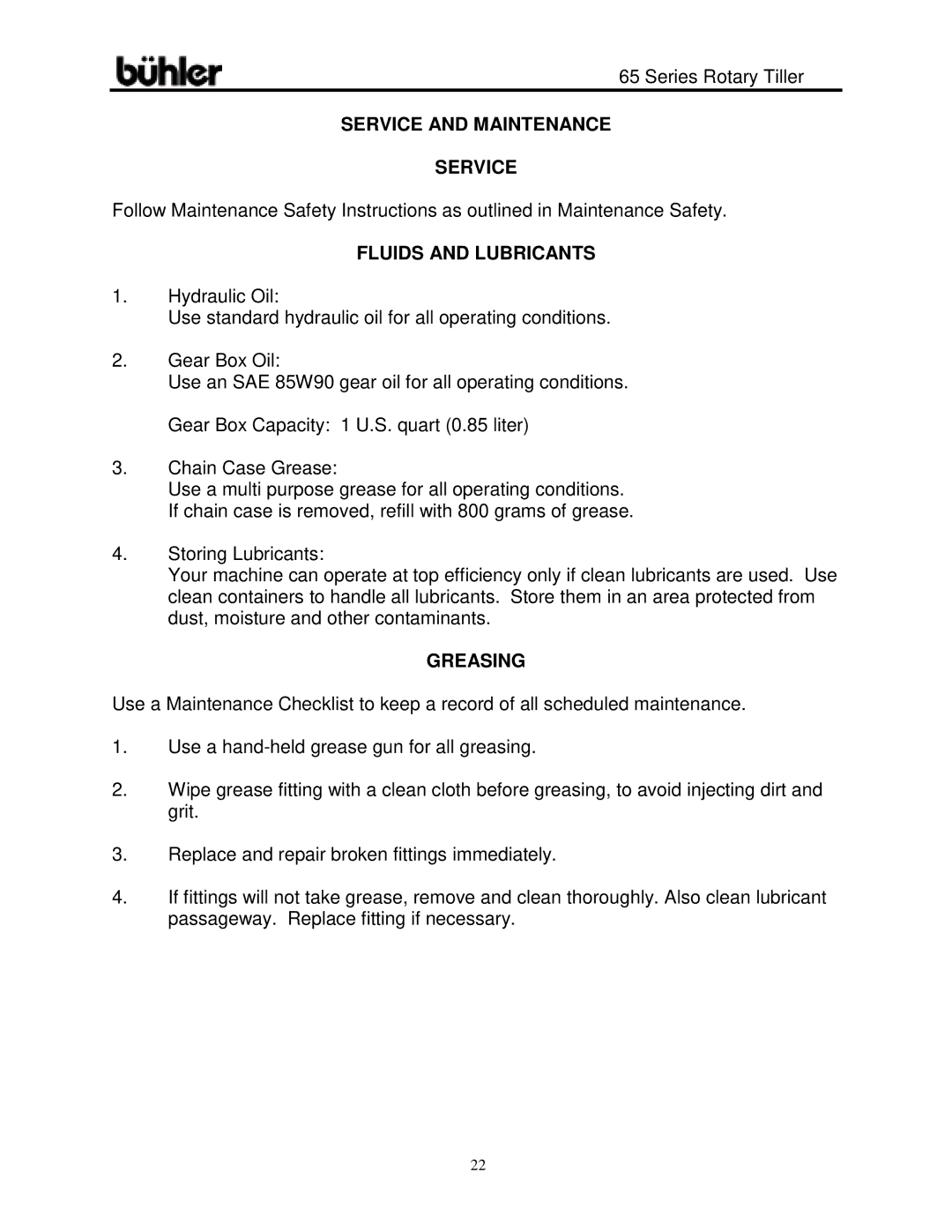

22