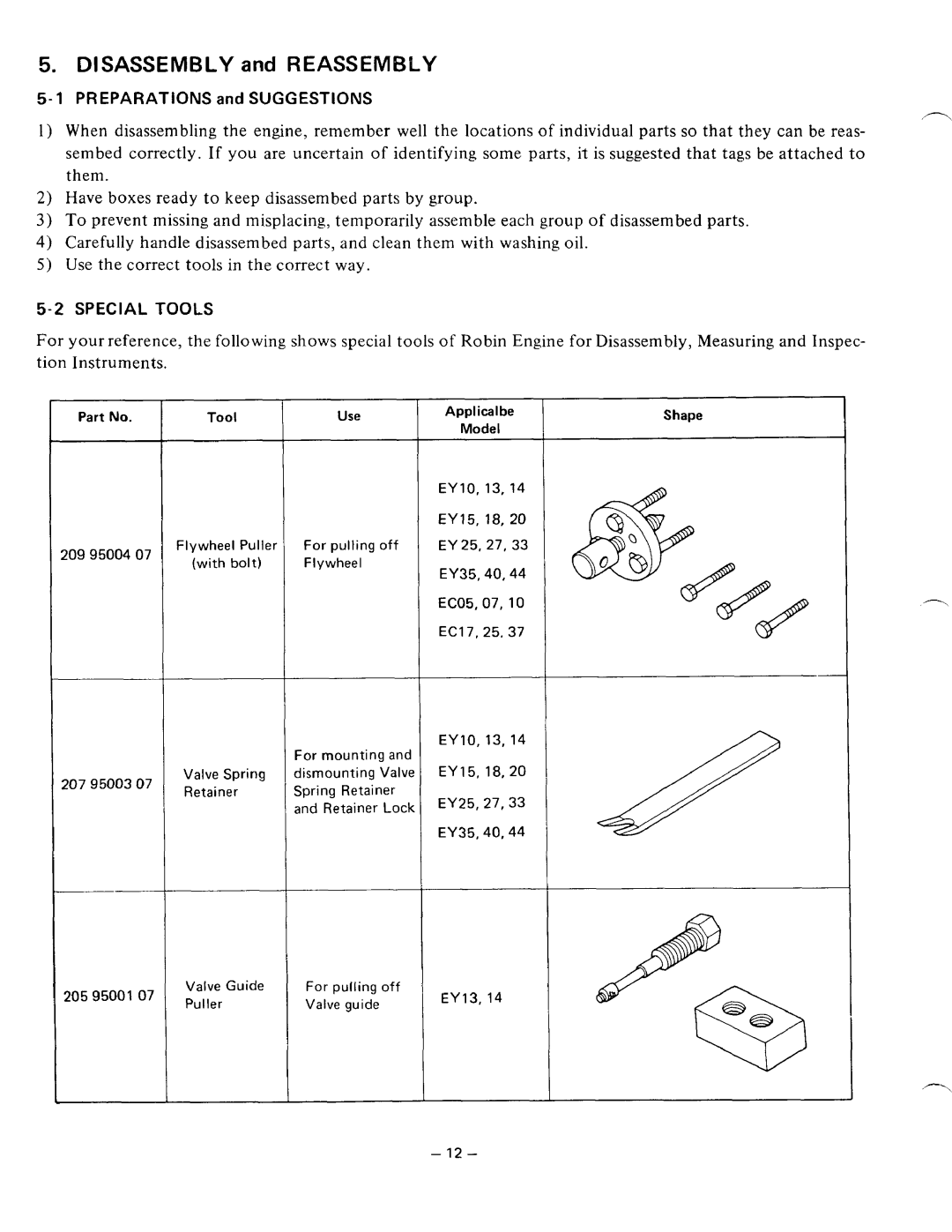

5-3 HOW TO DISASSEMBLE

|

|

| *Length of the bolt indicates the lengthfrom the bolt head bottom surfaceto the threaded end. |

| ||||||

Order |

| Item |

|

| Procedures |

| Remarks | Tool | ||

1 | Recoil starter | (1) | Removetherecoilstarter. |

|

| 10 mm box spanner |

| |||

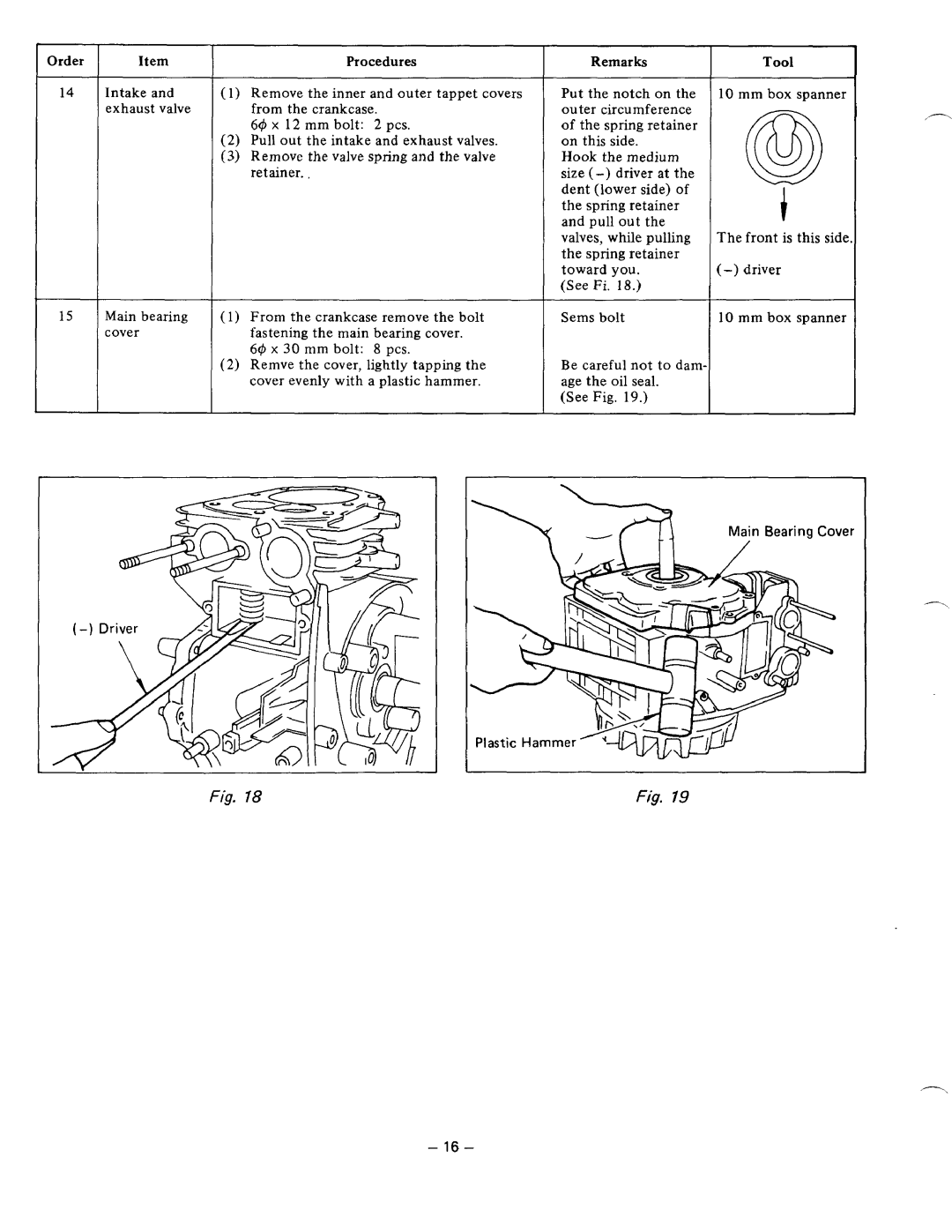

|

|

|

| 64 x 8 mm bolt: 4 pcs. |

|

|

|

| ||

2 | FueI tank | (1) | Close the fuel cock. |

|

| 10 mm box spanner |

| |||

|

|

| (2) From the carburetor disconnect the fuel |

| 10 mm box spanner |

| ||||

|

|

|

| pipe between the fuel strainer and carbu- |

|

|

| |||

|

|

|

| retor on the sideof the carburetor. |

|

|

| |||

|

|

| (3) Remove the tank band and fuel tank from |

|

|

| ||||

|

|

|

| the fuel tank bracket. |

|

|

|

| ||

|

|

|

| 6@x 12 mm bolt: 2 pcs. |

|

|

|

| ||

| ~ | ~~ | ~~ |

|

|

|

|

|

|

|

3 | Muffler and | (1) Remove the muffler and muffler cover from | Note that the EY20V | 12mmboxspanner |

| |||||

| muffler cover |

| the cylinder portionof the crankcase. | has 2 sheets of gasket | or 12 mm spanner |

| ||||

|

|

|

| 8@x 100 mm bolt: | 2 pcs. (EY 15V) | and 1 sheet of flange |

|

| ||

|

|

|

| 8@x 106 mm bolt: | 2 pcs.(EY2OV) | between the muffler |

|

| ||

|

|

|

|

|

|

|

| and cylinder. |

|

|

|

|

|

| ~~~ | ~~ | ~ | ~ |

|

|

|

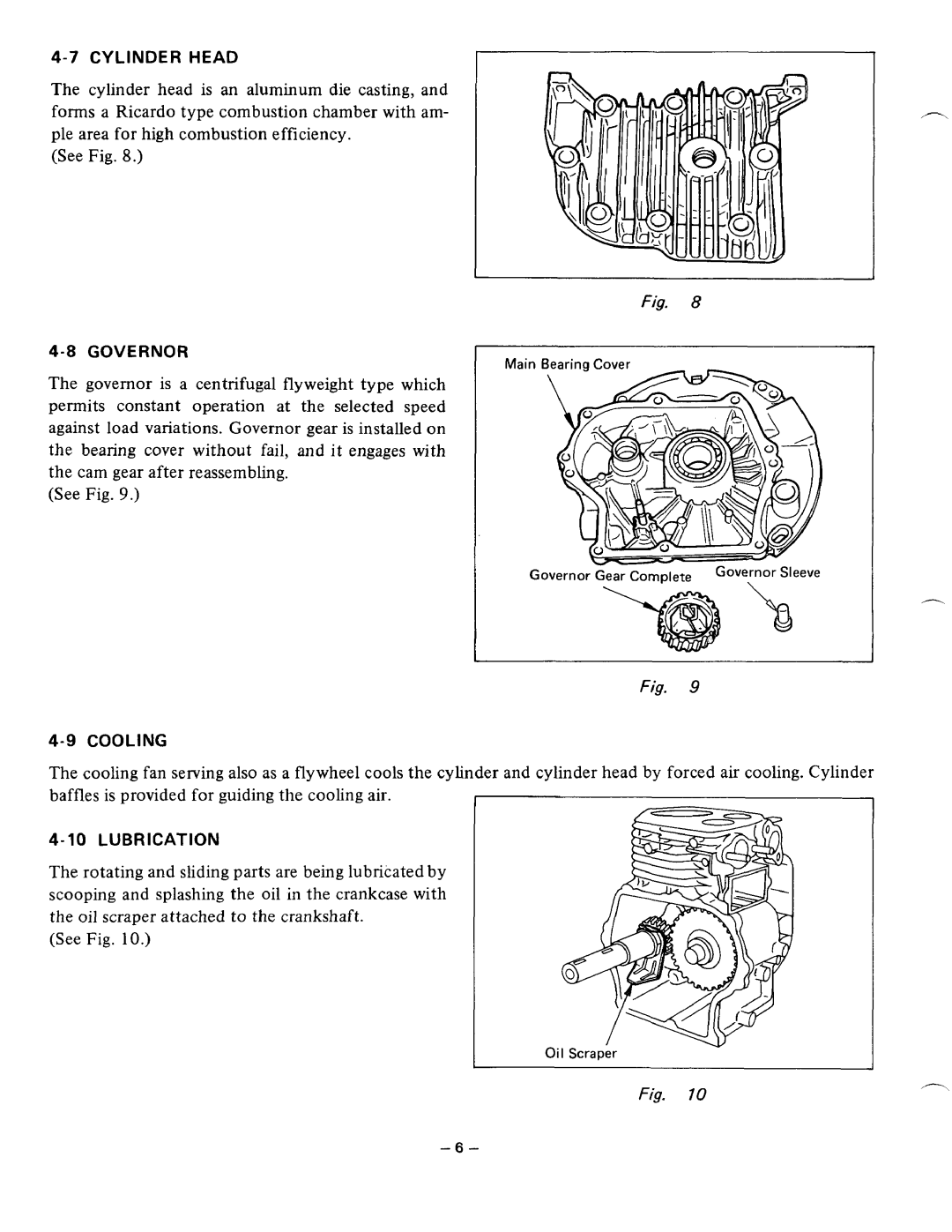

4 | Air cleaner | (1) Remove the air cleaner cover and element. | Air cleaner is fastened | 10 mm box spanner |

| |||||

|

|

| ( 2 ) Loosen the intake manifold mounting nut. | together with the car- |

|

| ||||

|

|

|

| 69 nut: 2 pcs. |

|

| buretor. |

|

| |

|

|

| (3) Remove the air cleaner case from the car- |

|

|

| ||||

|

|

|

| buretor and fuel tank bracket. |

|

|

| |||

|

|

|

| 6 9 n u t : 2 pcs. 6$ x 14 mm bolt: 1 pce. |

|

|

| |||

|

|

| (4) | Disconnectthebreatherpipe. |

|

|

|

| ||

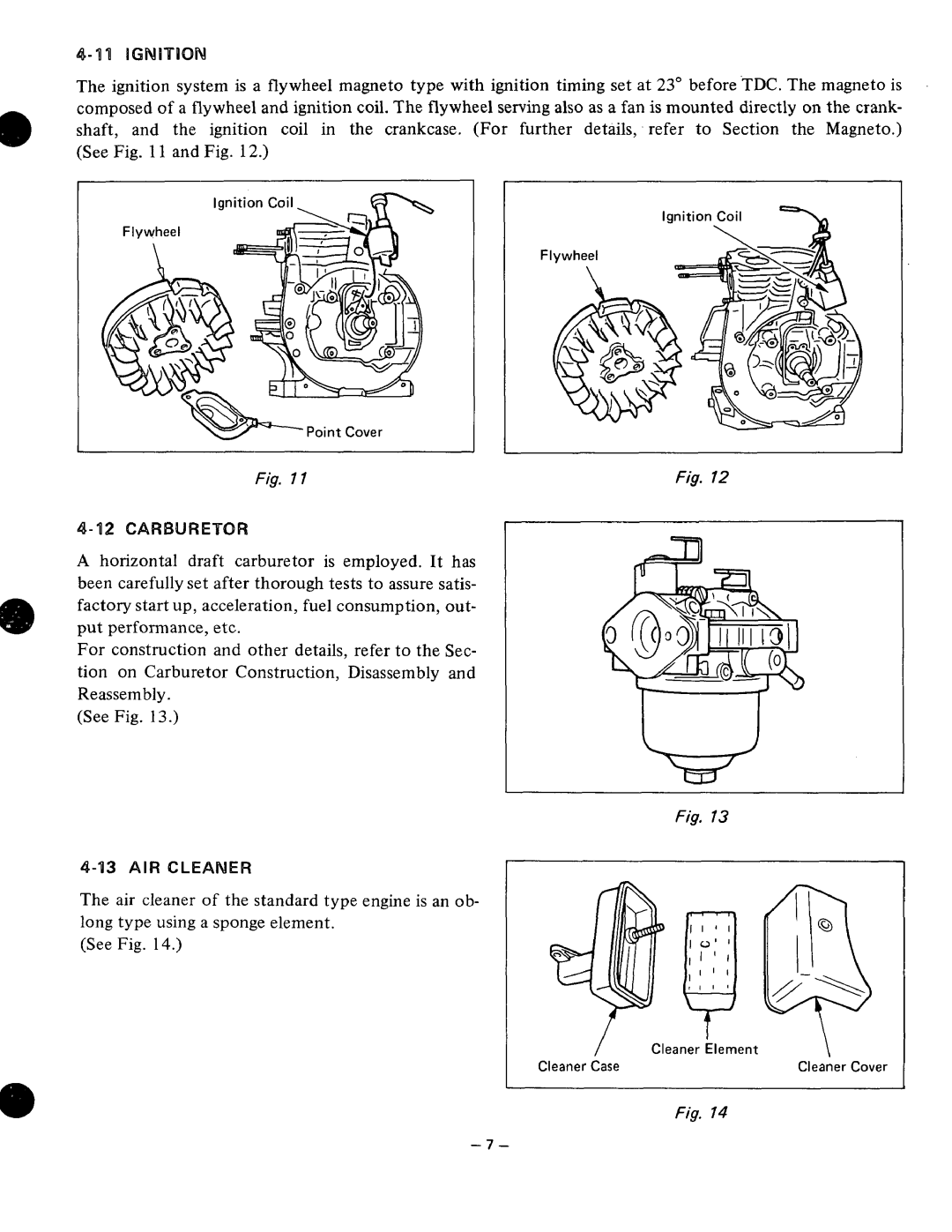

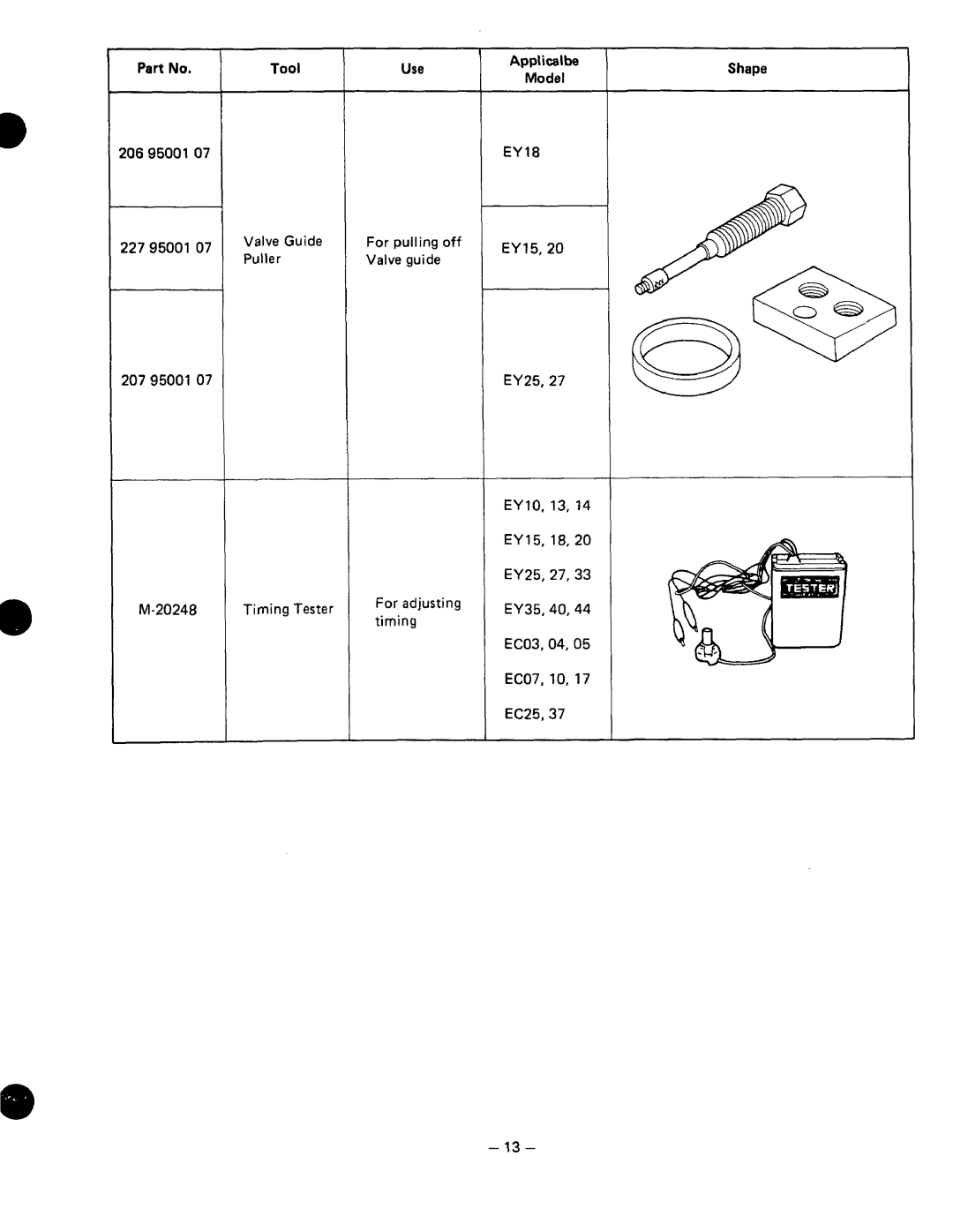

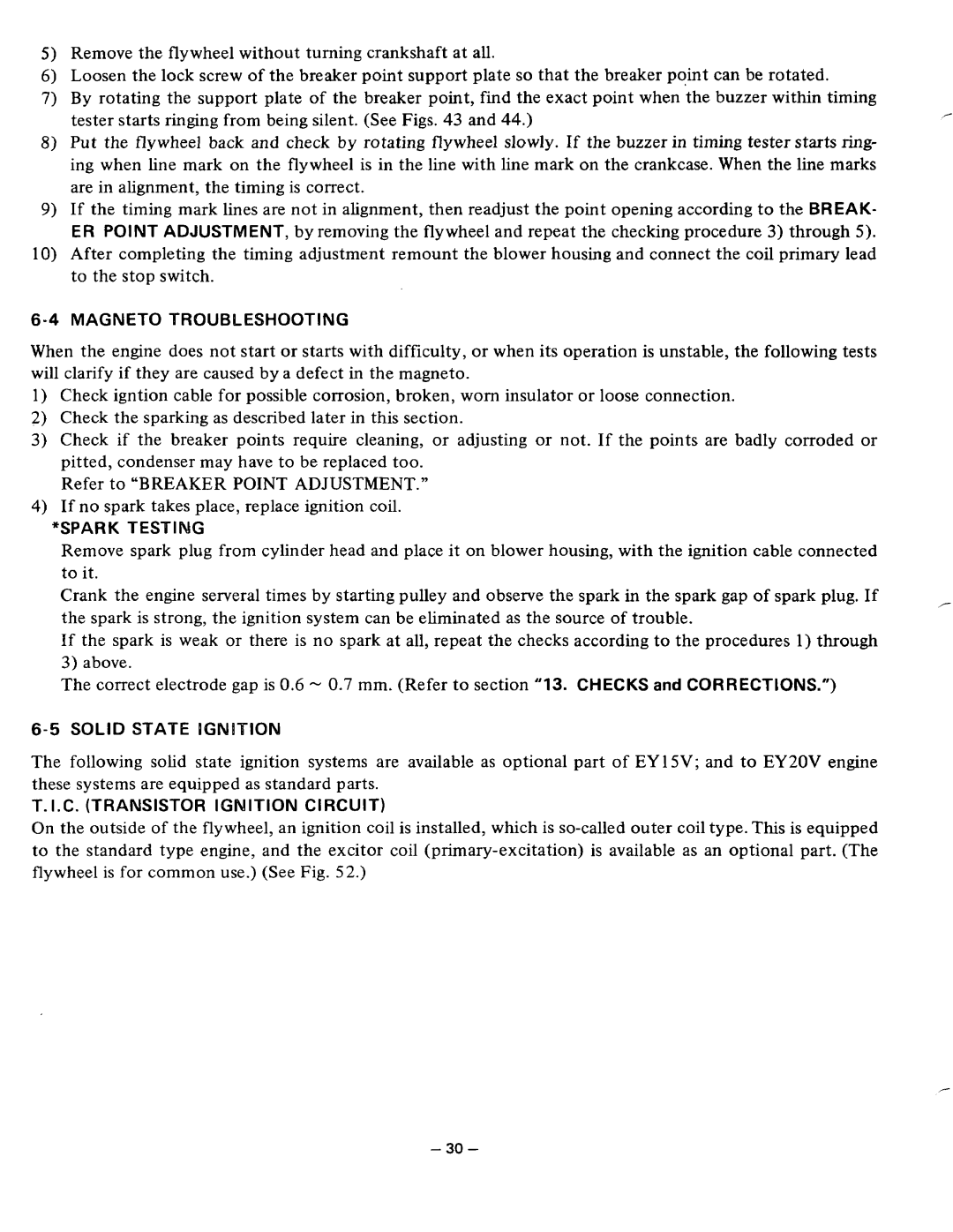

| Governor lever | (1) Remove the choke | lever from the fuel tank | Special bolt | 14 mm box spanner |

| ||||

| and the relative |

| bracket and remove the choke rod from |

| or 14 mm spanner |

| ||||

| parts |

|

| the carburetor, |

|

|

|

|

| |

|

|

|

| Specialbolt: | 1 pce. |

|

| Just loosen the bolt, | 10 mm box spanner |

|

|

|

| (2) Remove the governor lever from the |

| ||||||

|

|

|

| governor lever shaft. |

| unnecessary to the |

|

| ||

|

|

|

| 64 x 2 5 mmbolt:1pce. |

|

|

|

| ||

|

|

| (3) Remove the governor rod and rod spring |

|

|

| ||||

|

|

|

| from the carburetor. |

|

|

|

| ||

|

|

| (4) Remove the governor spring from the |

|

|

| ||||

|

|

|

| speed control lever. |

|

|

|

| ||

| Carburetor | (1) Remove the carburetor from the intake |

|

|

| |||||

|

|

|

| manifold. |

|

|

|

|

|

|

|

|

| ~ | ~~ |

|

|

|

|

|

|

7 | Intake manifold | (1) Remove the intake manifold from the |

| 10 mm box spanner |

| |||||

|

|

|

| cylinder portion of the crankcase. |

|

|

| |||

|

|

|

| 6q5 nut: 2 pcs. |

|

|

|

|

| |

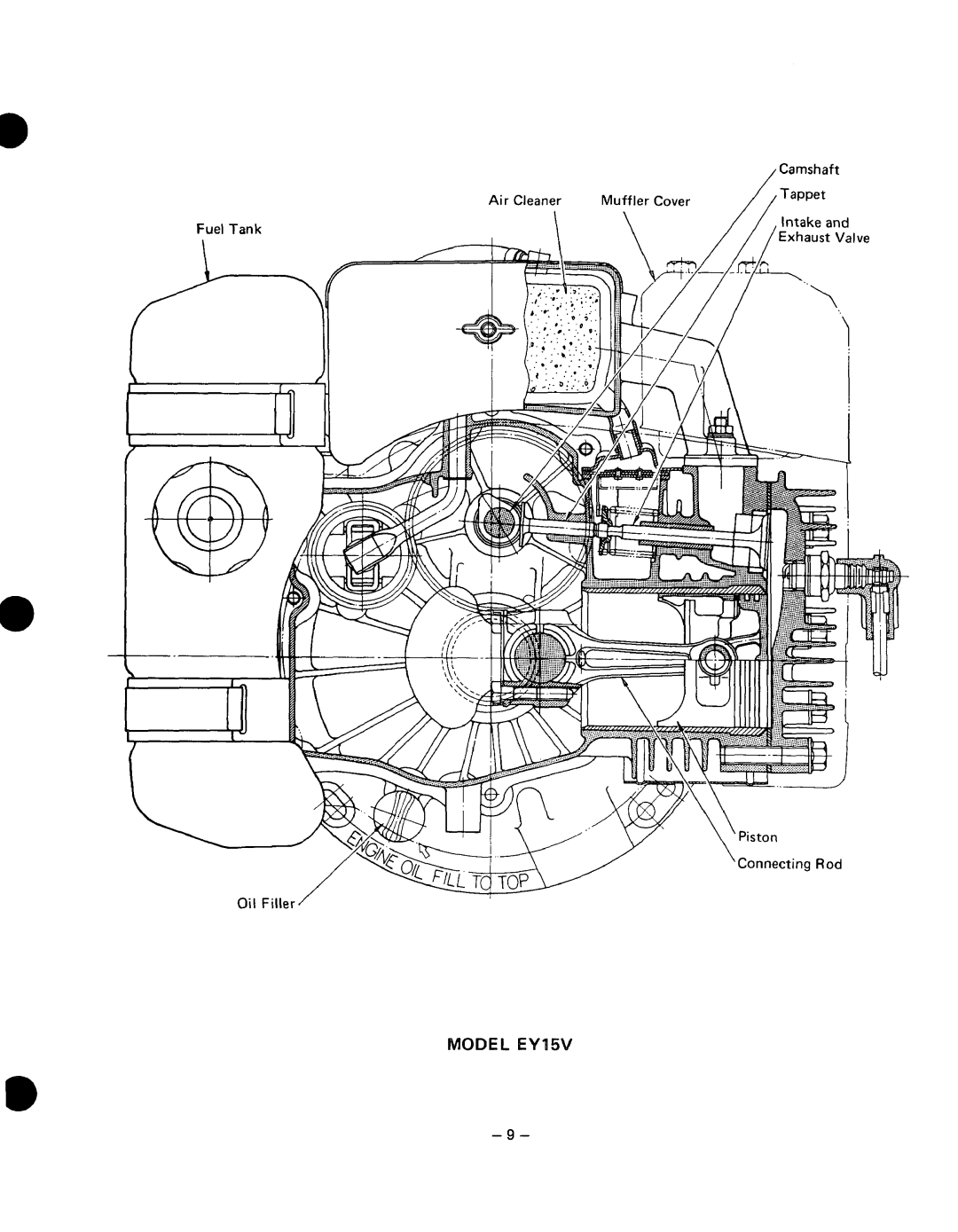

8 | Fuel | tank | (1) Remove the fuel tank bracket from the |

| 10 mrn box spanner |

| ||||

| bracket |

| crankcase. |

|

|

|

|

|

| |

|

|

|

| 64 x 14 mm |

|

|

| |||

|

|

|

| 64 x 10 mmbolt:2pcs. |

|

|

|

| ||

|

|

|

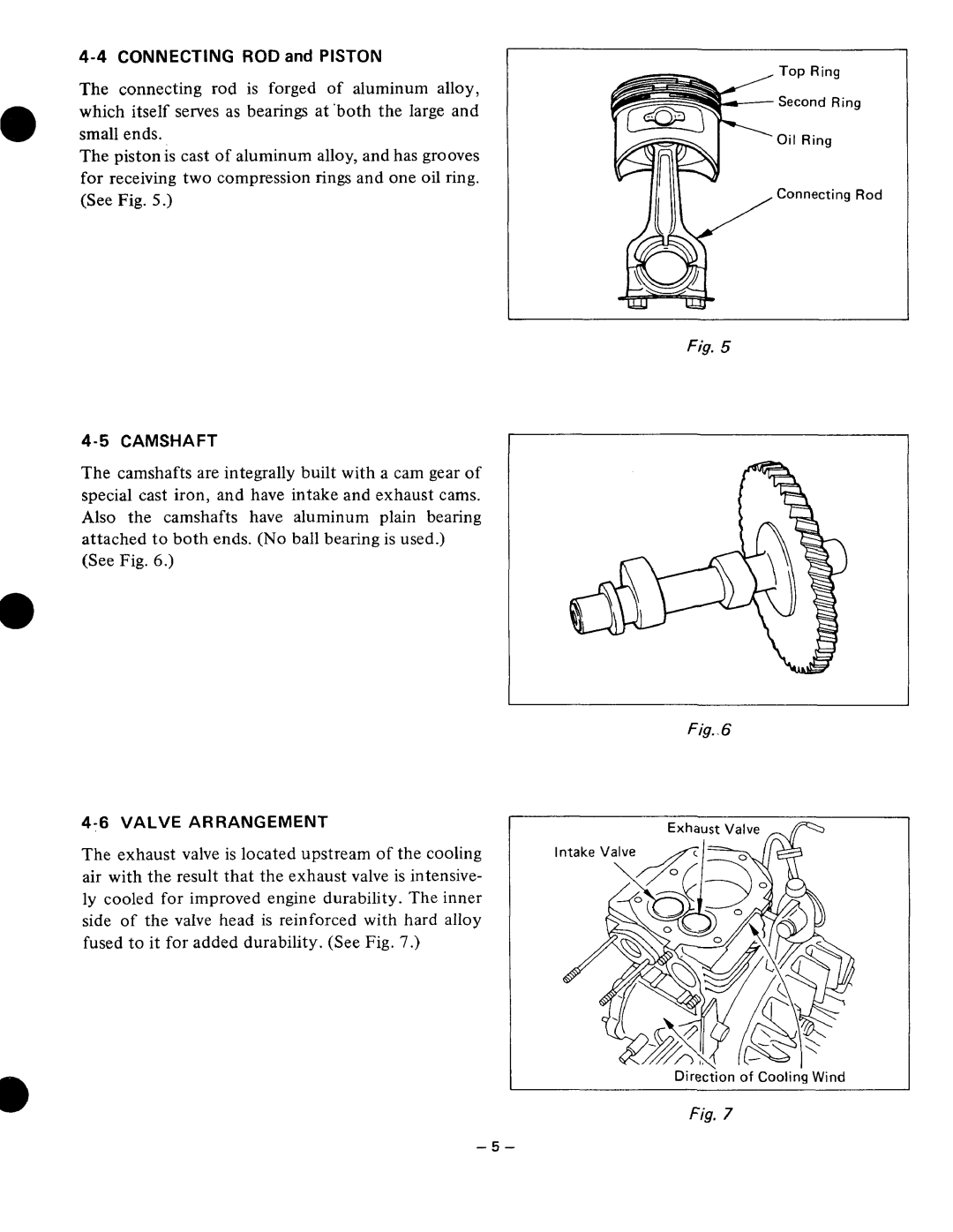

| \ Rod Spring \ | Choke Rod | SpeedControl Lever |

|

| ||

|

|

|

|

|

|

|

| Fuel Tank Bracket |

|

|

Governor Lever / Governor Shaft |

|

Fig. 75

- 14-