SECTION 3

SET-UP ADJUSTMENTS

The following adjustments should be made when a | Perform the adjustments in order as follows: | ||

complete realignment is required or a new picture | 1. | Beam Landing | |

tube is installed. | |||

| 2. | Convergence | |

These adjustments should be performed with rated | 3. | Focus | |

power supply voltage unless otherwise noted. | 4. | Screen (G2)/White Balance | |

The controls and switch should be set as follows | Note: Test Equipment Required | ||

unless otherwise noted: |

| 1. | Color Bar Pattern Generator |

|

| ||

PICTURE control ................. normal |

| 2. | Degausser |

|

| 3. | DC Power Supply |

BRIGHTNESS control ......... normal |

| 4. | Digital Multimeter |

|

|

|

|

3-1. BEAM LANDING

Preparation:

•Input a white pattern signal.

•Face the picture tube in a East or West direction to reduce the influence of geomagnetism.

NOTE: Do not use the hand degausser because it magnetizes the CRT .

1.Input white pattern from pattern generator.

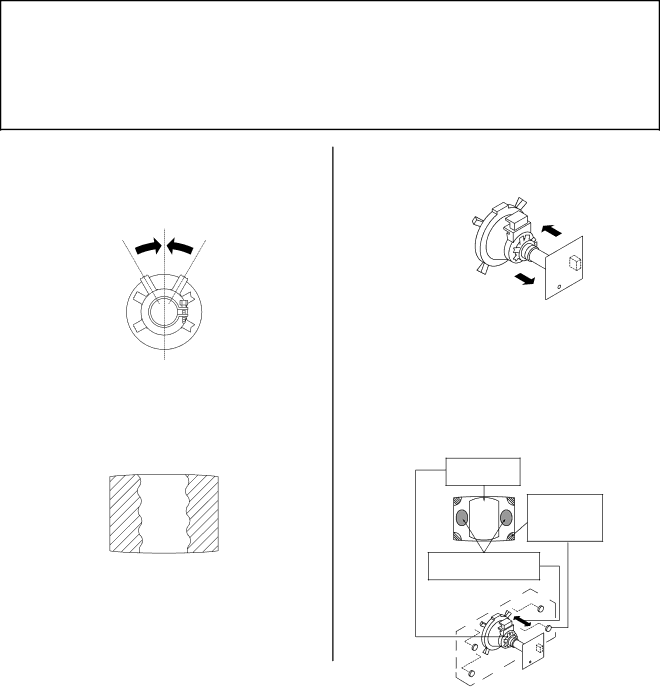

2.Loosen the deflection yoke mounting screw, and set the purity control to the center as shown below:

3.Input green pattern from pattern generator.

4.Move the deflection yoke backward, and adjust with the purity control so that green is in the center and red and blue are even on both sides.

![]() B R

B R ![]()

G

5.Move the deflection yoke forward, and adjust so that the entire screen becomes green.

6.Switch over the raster signal to red and blue and confirm the condition.

7.When the position of the deflection yoke is determined, tighten it with the deflection yoke mounting screw.

8.When landing at the corner is not right, adjust by using the disk magnets.

Purity control

corrects this area.

b | a | Disk magnets or | |

rotatable disk | |||

|

| ||

c | d | magnets correct | |

these | |||

|

| ||

Deflection yoke positioning | |||

corrects these areas. |

| ||

b

c

a

d

— 12 —