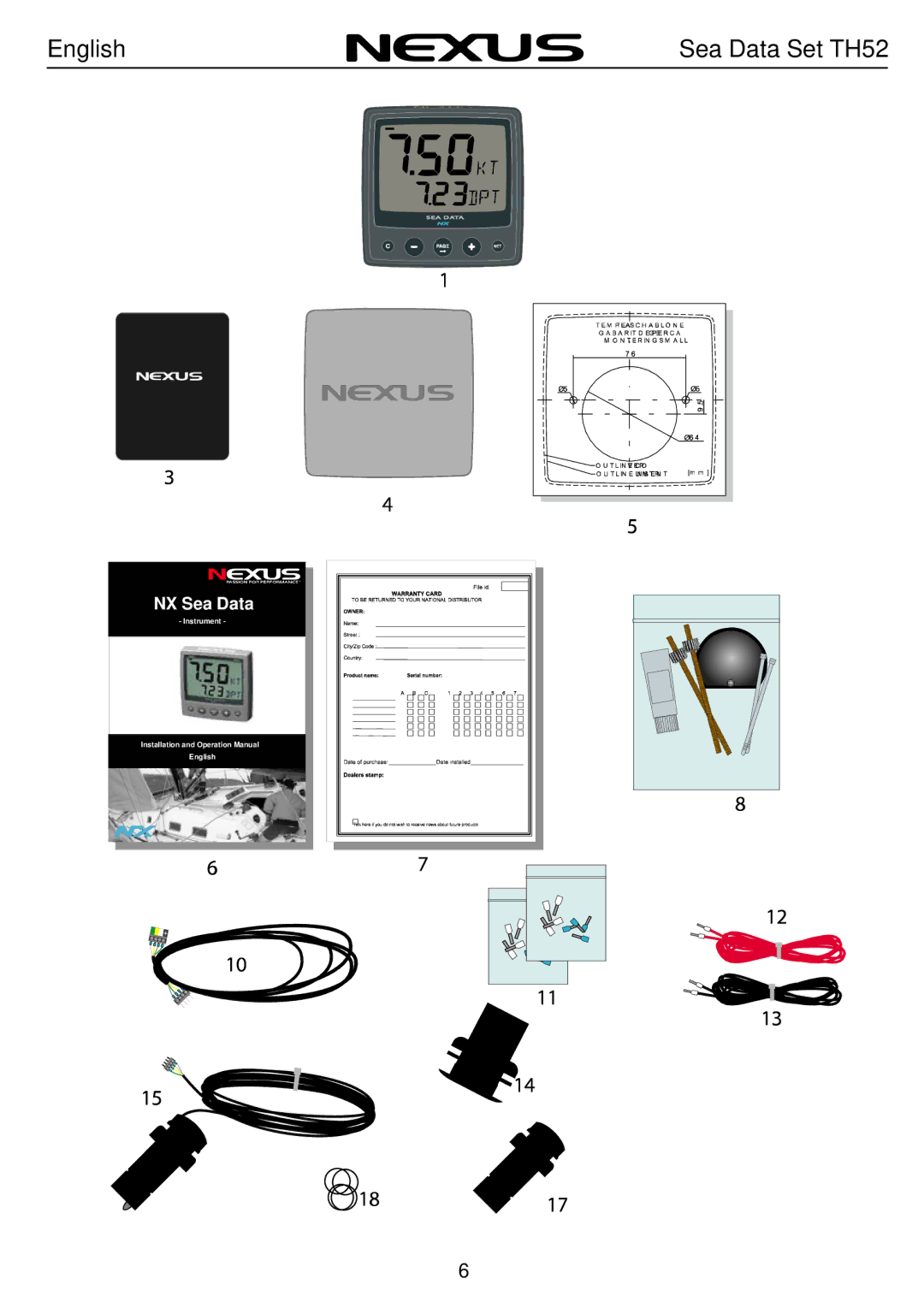

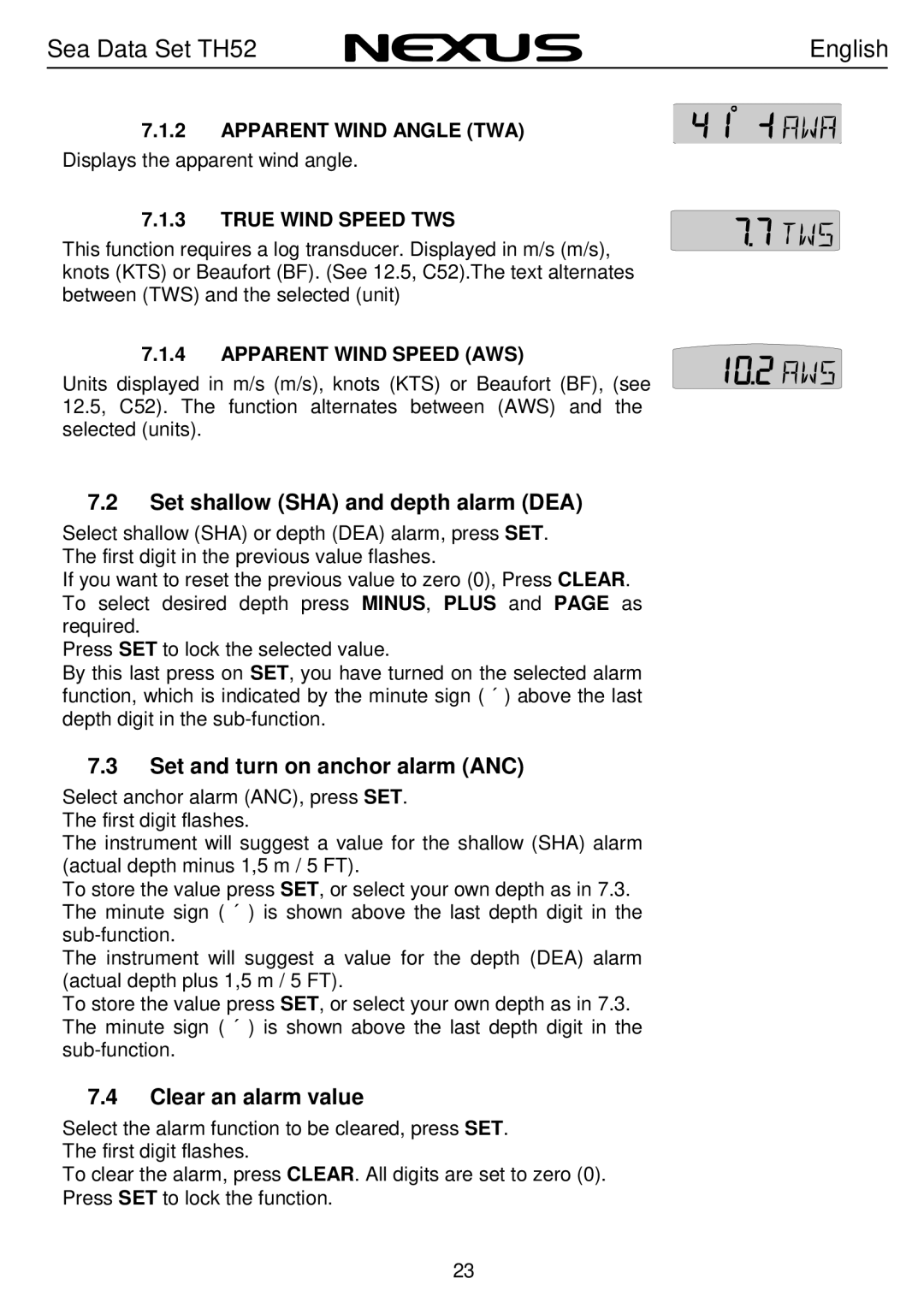

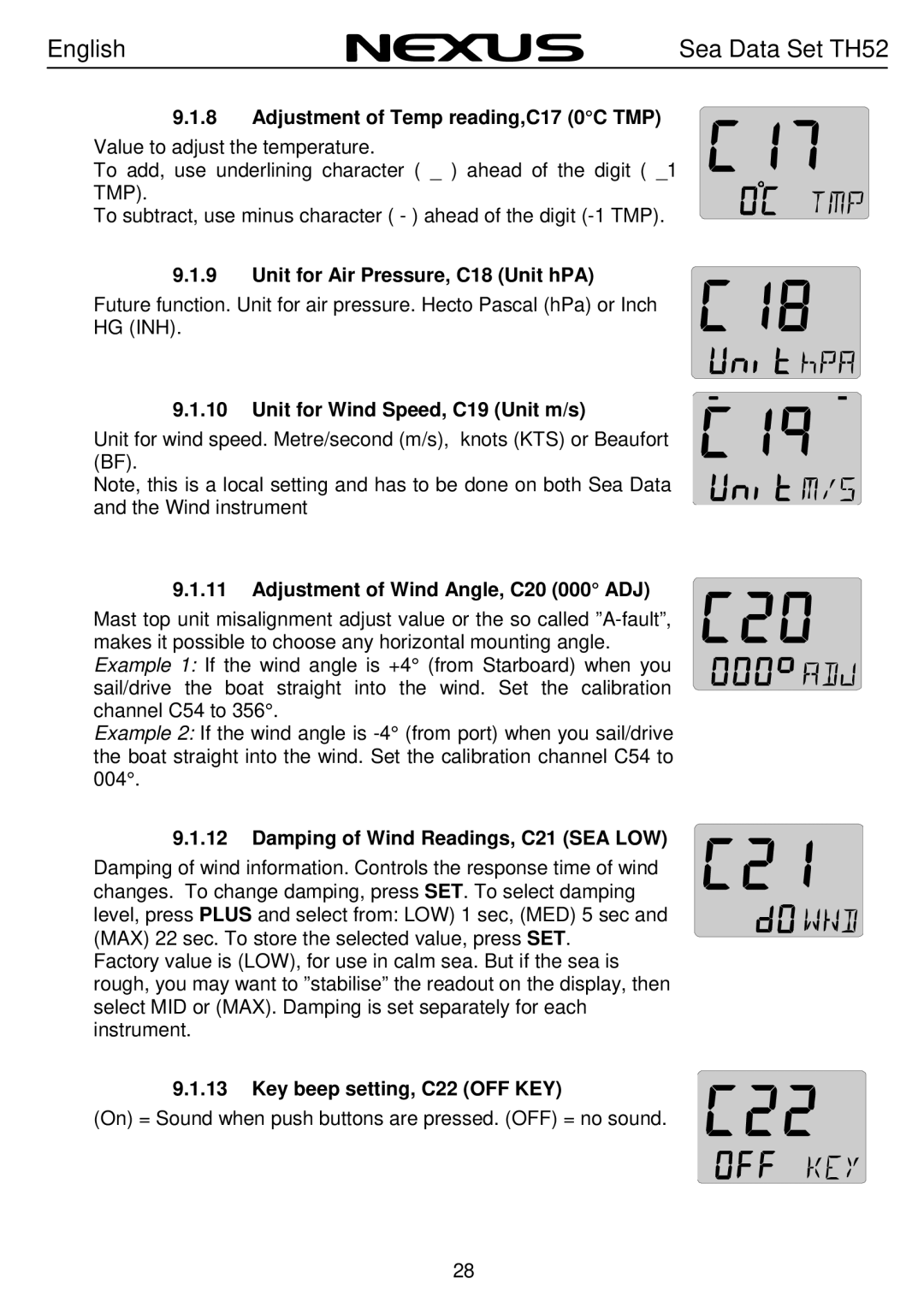

English | Sea Data Set TH52 |

10.Attach one safety ring to one end of the retaining pin. Slide the retaining pin through the valve assembly and paddlewheel insert. Attach the second safety ring to the retaining pin (see Figure 2).

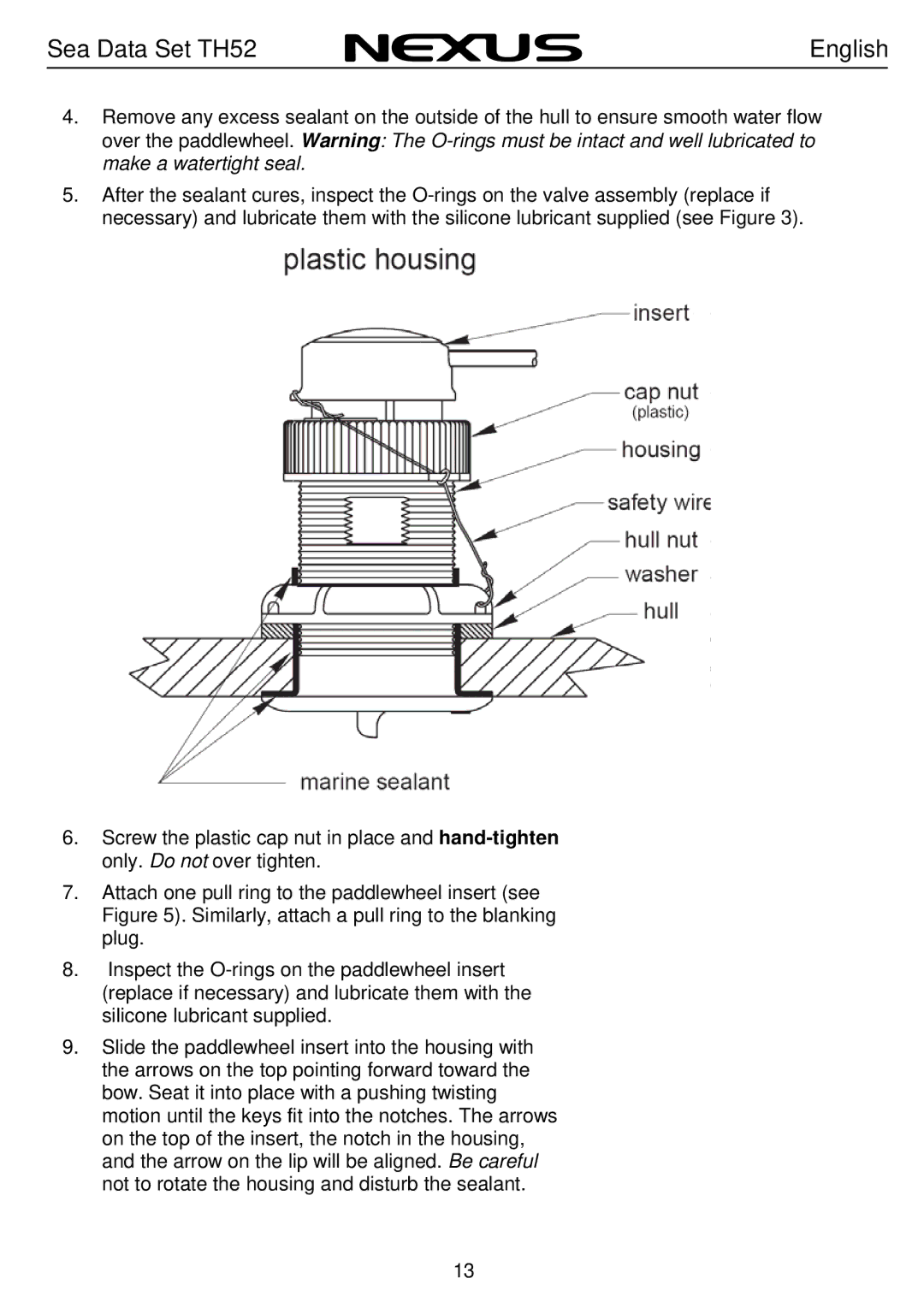

Warning: Always attach the safety wire to prevent the insert from backing out in the unlikely event that the cap nut fails or is screwed on incorrectly.

11. Attach the safety wire to one eye in the hull nut. Thread the short emergency plug onto the wire. Lead the wire in a counterclockwise direction and thread it through one eye in the cap nut. Thread the wire through the eye a second time. Then lead the wire through the pull ring and the second eye in the cap nut. Twist the wire securely to itself.

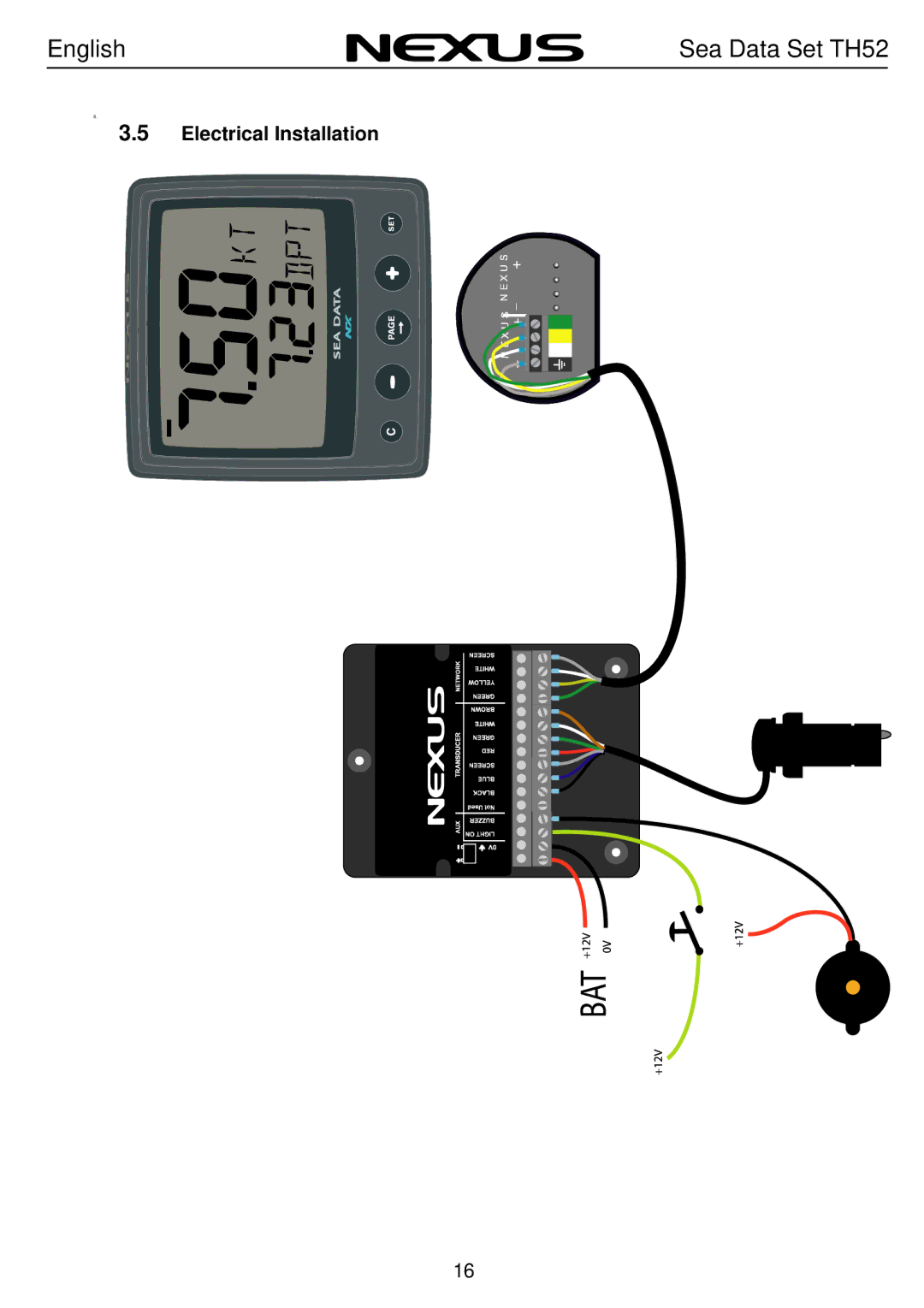

12.Route the cable to the instrument being careful not to tear the cable jacket when passing it through the bulkhead(s) and other parts of the boat. To reduce electrical interference, separate the sensor cable from other electrical wiring and the engine. Coil any excess cable and secure it in place with

13.Refer to the instrument owner’s manual to connect the sensor to the instrument.

3.3Checking for Leaks

Warning: Never install a

When the boat is placed in the water, immediately check around the

3.4Installation in a Cored Fiberglass Hull

The core (wood or foam) must be cut and sealed carefully. The core must be protected from water seepage, and the hull must be reinforced to prevent it from crushing under the hull nut allowing the housing to become loose. Warning: Always wear safety goggles and a dust mask.

14