2-3. Dimensions And Weights

A

B

Front

D

C

|

| Dimensions | |

|

|

| |

| Height | 21 in (533 mm) | |

|

|

| |

| Width | ||

|

|

| |

| Length | ||

|

|

| |

| A | ||

|

|

| |

| B | 13/16 in (21 mm) | |

|

|

| |

| C | ||

|

|

| |

| D | ||

E 4 Holes |

|

| |

E | 1/2 (13 mm) | ||

| |||

|

|

| |

|

| Weight | |

|

|

| |

|

|

| |

| 210 lbs (95 kg) | ||

|

| ||

|

|

|

2-4. Specifications

| Rated Output at 40% | Rated Input, |

|

| Welding Amperage | Max. |

Mode | Duty Cycle | 60 HZ, | KVA | KW | Range | Voltage |

|

|

|

|

|

|

|

DC TIG | 150 Amps at 16 Volts | 230 | 8.7 - (0.50)* | 4.0 - (0.3)* | 80 | |

|

|

|

|

|

|

|

DC Stick | 150 Amps at 26 Volts | 230 | 9.7 - (0.50)* | 5.7 - (0.3)* | 80 | |

|

|

|

|

|

|

|

AC TIG | 150 Amps at 16 Volts | 230 | 15.5 - (0.50)* | 4.9 - (0.3)* | 80 | |

|

|

|

|

|

|

|

AC Stick | 150 Amps at 26 Volts | 230 | 12.2 - (0.50)* | 6.2 - (0.3)* | 80 | |

|

|

|

|

|

|

|

* () While idling.

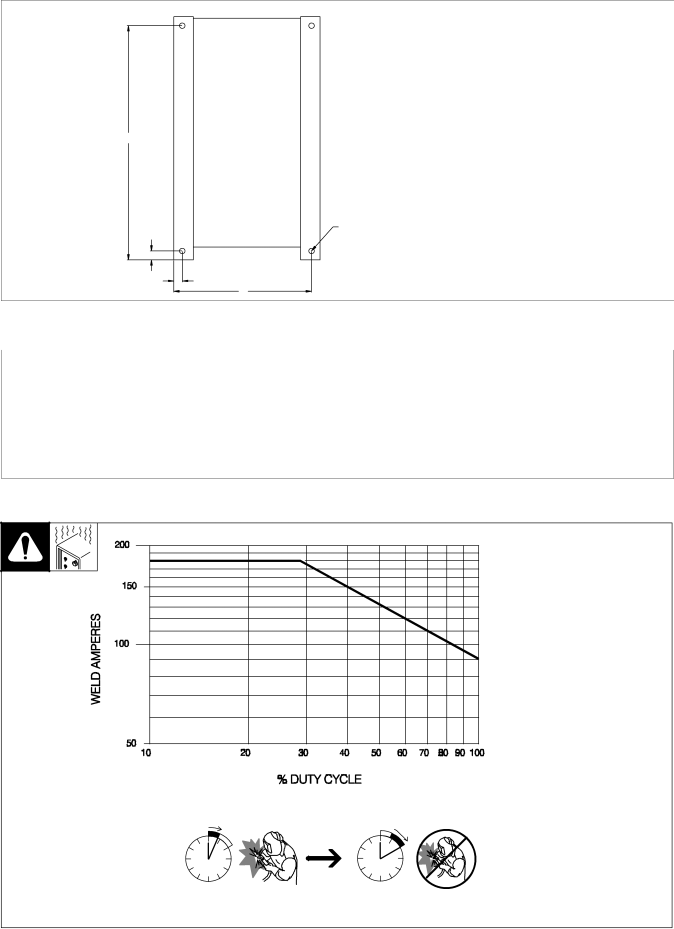

2-5. Duty Cycle Chart

40% Duty Cycle at 150 A AC/DC |

Duty cycle is percentage of 10 minutes that unit can weld at rated load without overheating.

YExceeding duty cycle can damage unit and void warranty.

4 Minutes Welding | 6 Minutes Resting |