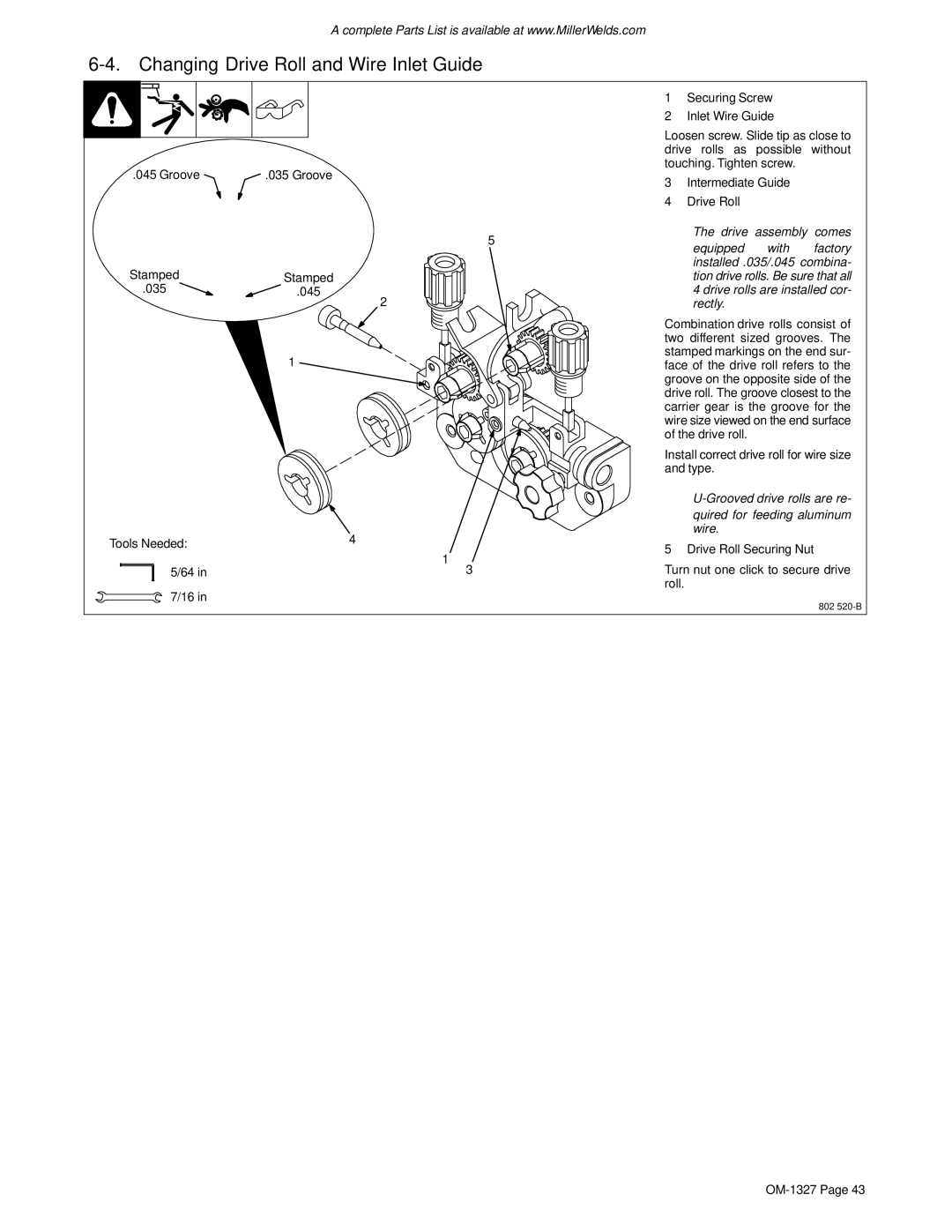

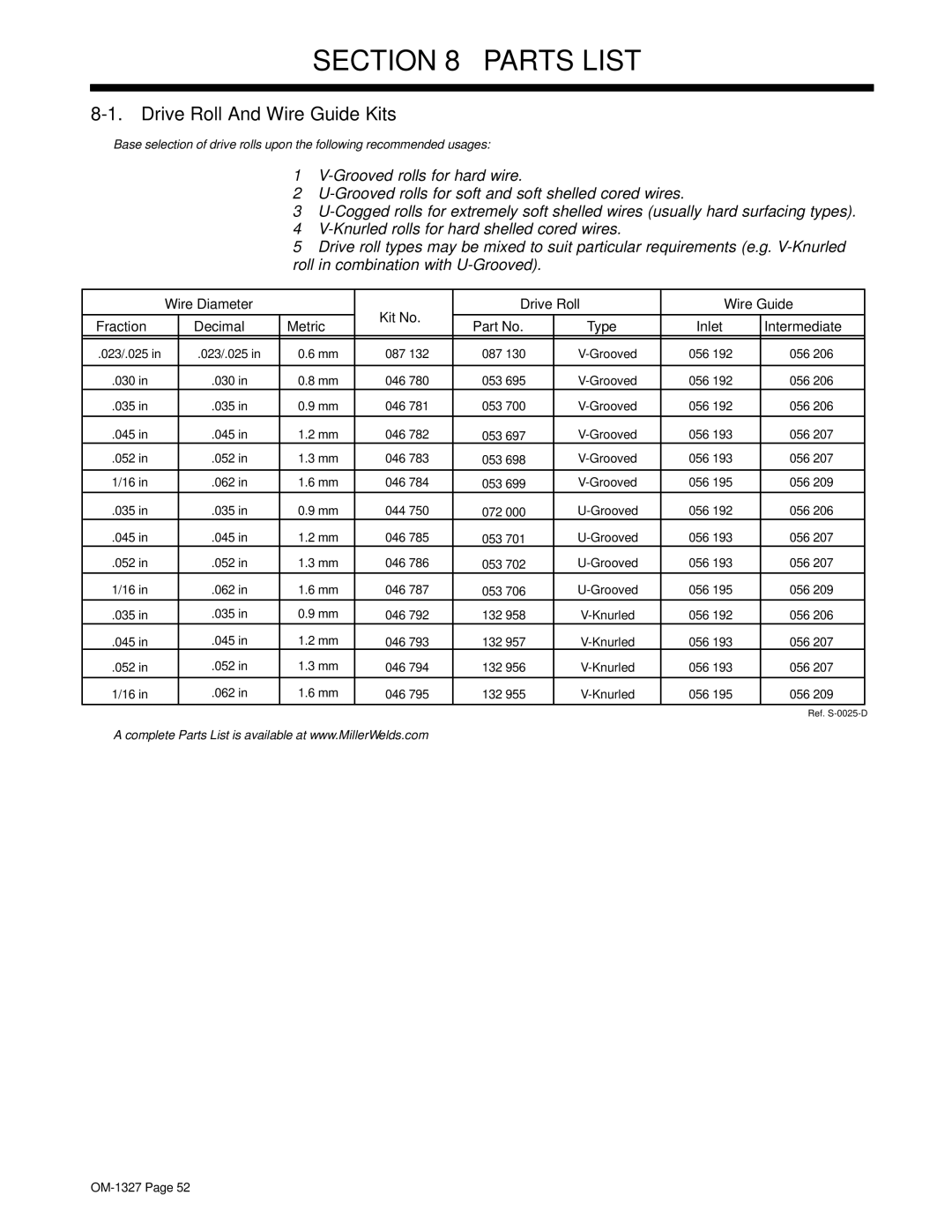

.A complete Parts List is available at www.MillerWelds.com

5-3. Timers

1 ![]()

2 ![]()

3

4

5

6 ![]()

8 | 9 |

7

Ref. 213

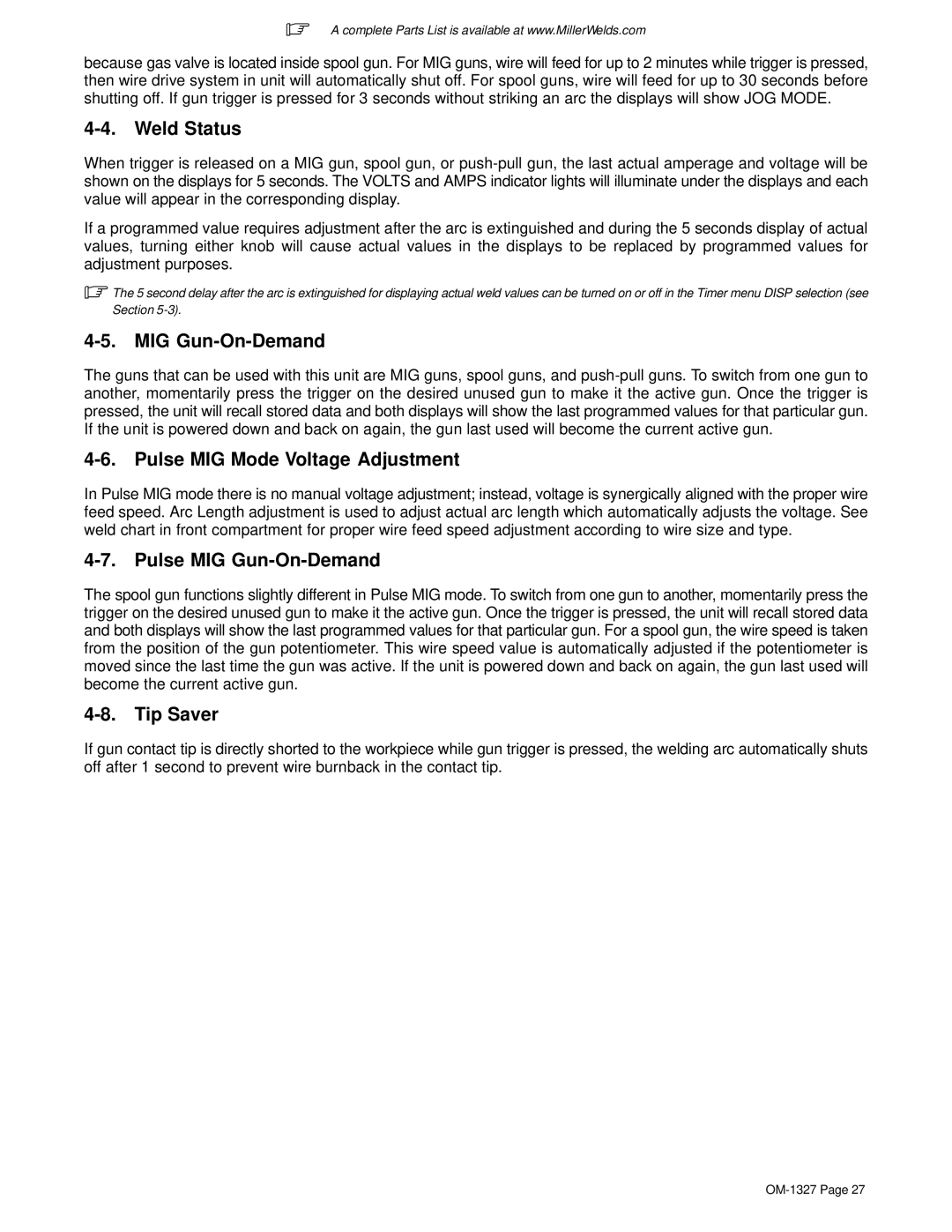

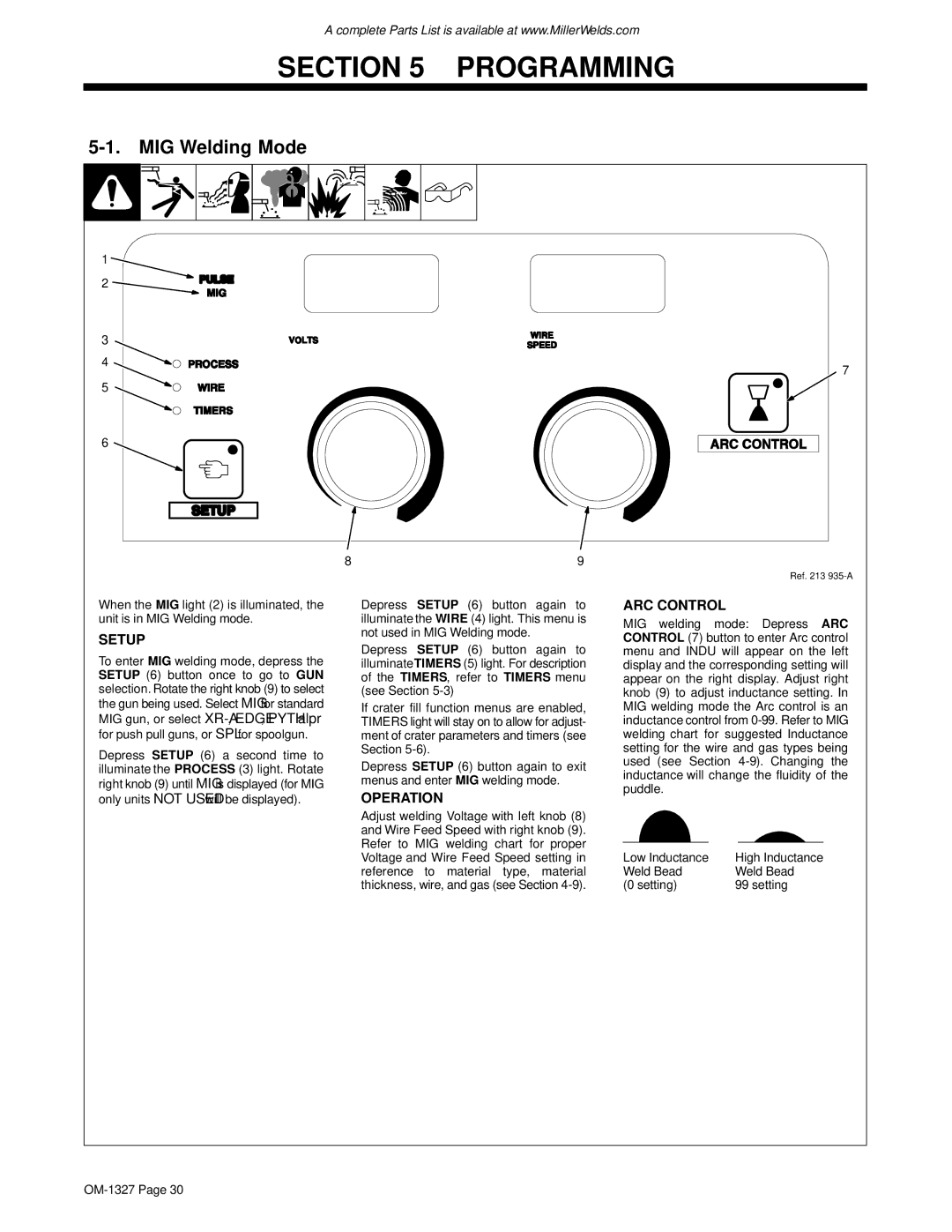

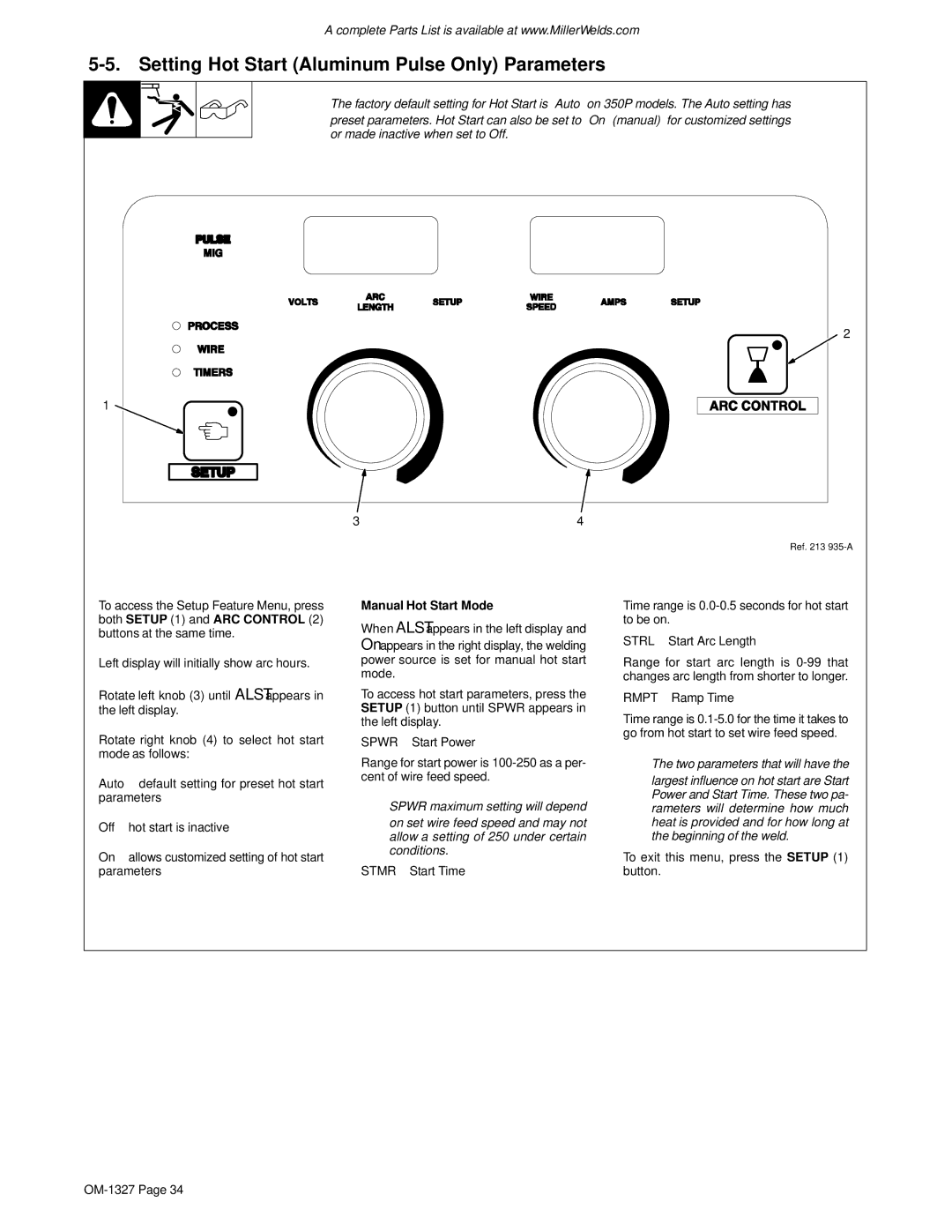

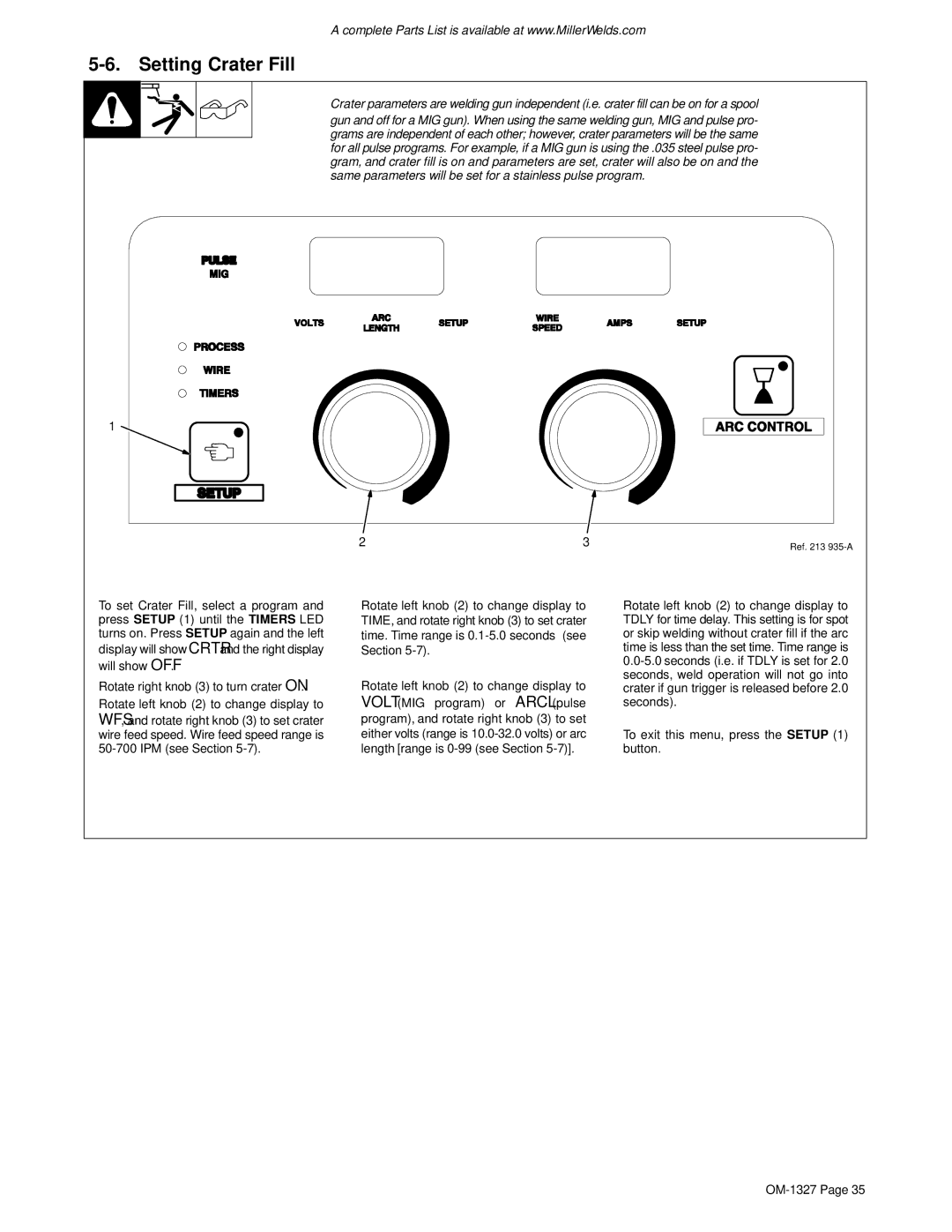

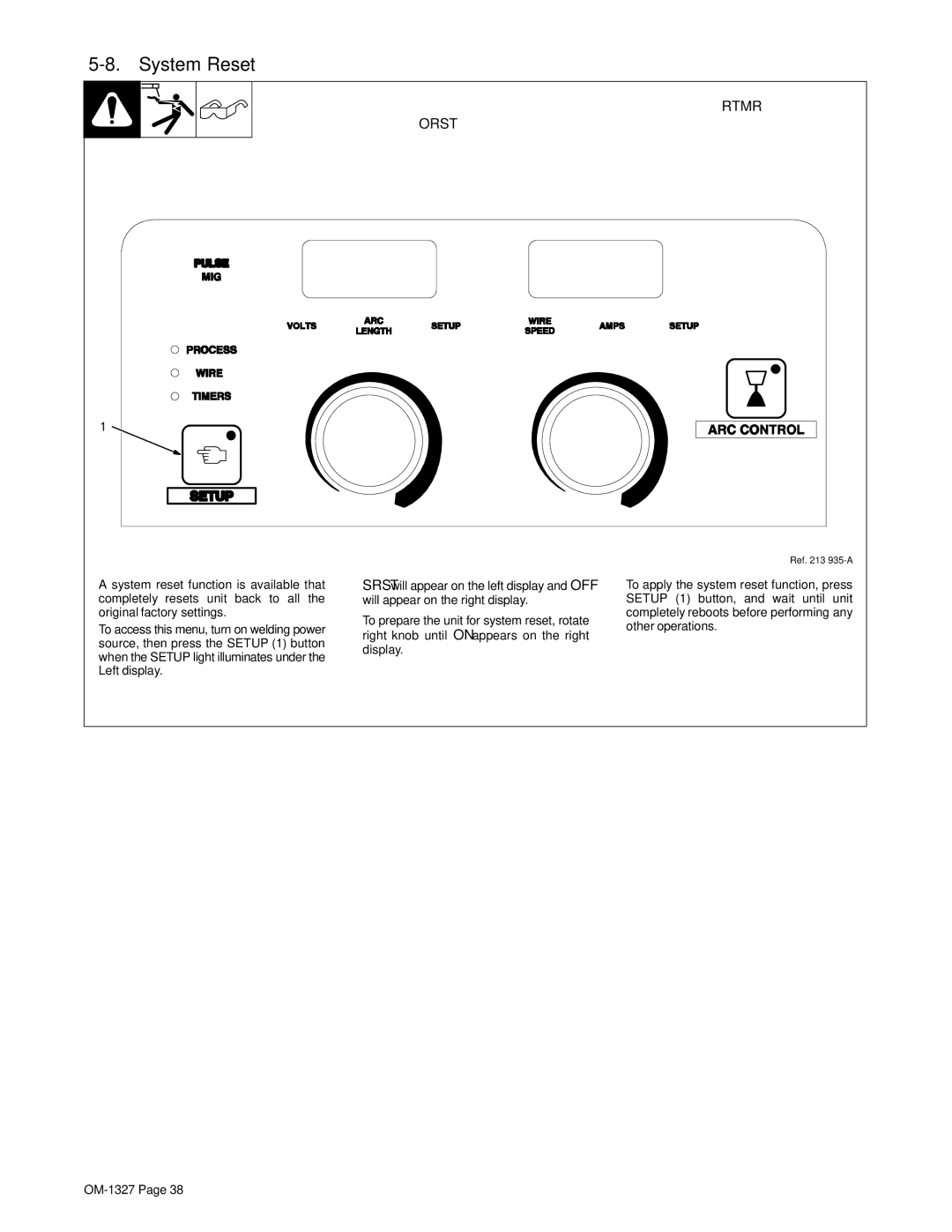

To enter the TIMERS (5) menu depress the SETUP (6) button 4 times or until the TIMERS light (5) is illuminated.

Items that can be adjusted in this menu are:

Preflow (PRE) − The amount of time that the shielding gas will flow after the trigger is

depressed and before the welding arc will be allowed to be active. Range of setting is from

Postflow (POST) − The amount of time that the shielding gas will flow after the arc has been shut off. Range of setting is

Spot Timer (SPOT) − The amount of time that the arc will be active before it shuts off automatically. Range of setting is from

Display (DISP) − Allows the Wire Speed display to show actual welding amperage while arc is active and for 5 seconds after arc is shut off. Setting is either AMPS or WFS for standard Wire Feed Speed.

Once in the TIMERS (5) menu, rotate the left knob (8) to find a particular item, and ro- tate the right knob (9) to change setting or status.

Depress SETUP (6) button to get out of TIMERS (5) menu and to enter welding mode.