47-393-40, 47-393-41, 47-393-39, 47-393-42 specifications

The Baxi Potterton 47-393-42, 47-393-39, 47-393-41, and 47-393-40 are models of high-efficiency gas boilers designed for residential heating. These models are well-known for their reliability, advanced technology, and user-friendly features, making them a popular choice among homeowners looking to improve their heating systems.One of the standout features of these models is their energy efficiency. Each unit is engineered to comply with stringent energy-saving regulations, significantly reducing utility bills while maintaining optimal heating performance. They are rated with impressive efficiency ratings, which can lead to long-term savings and a reduced carbon footprint.

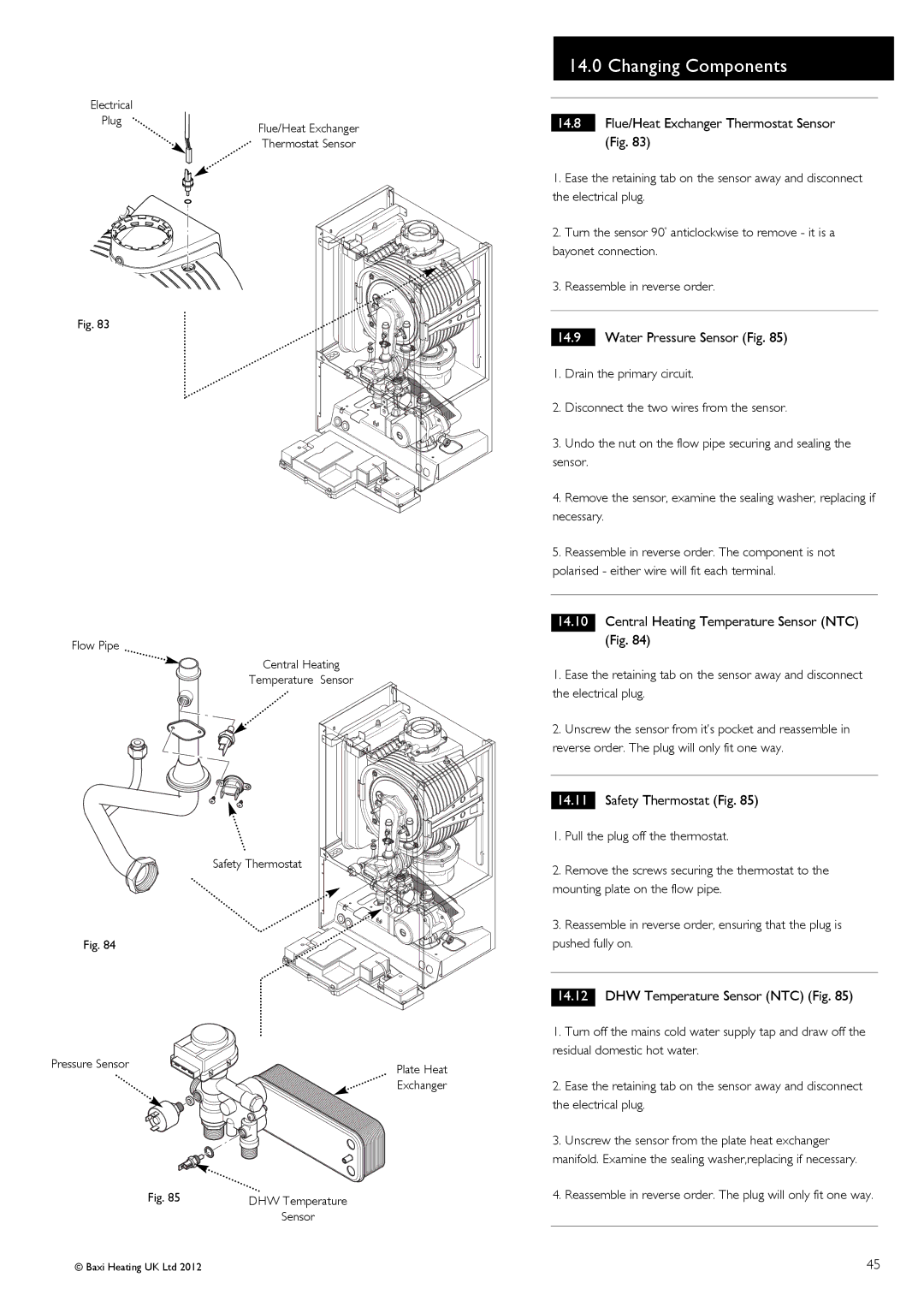

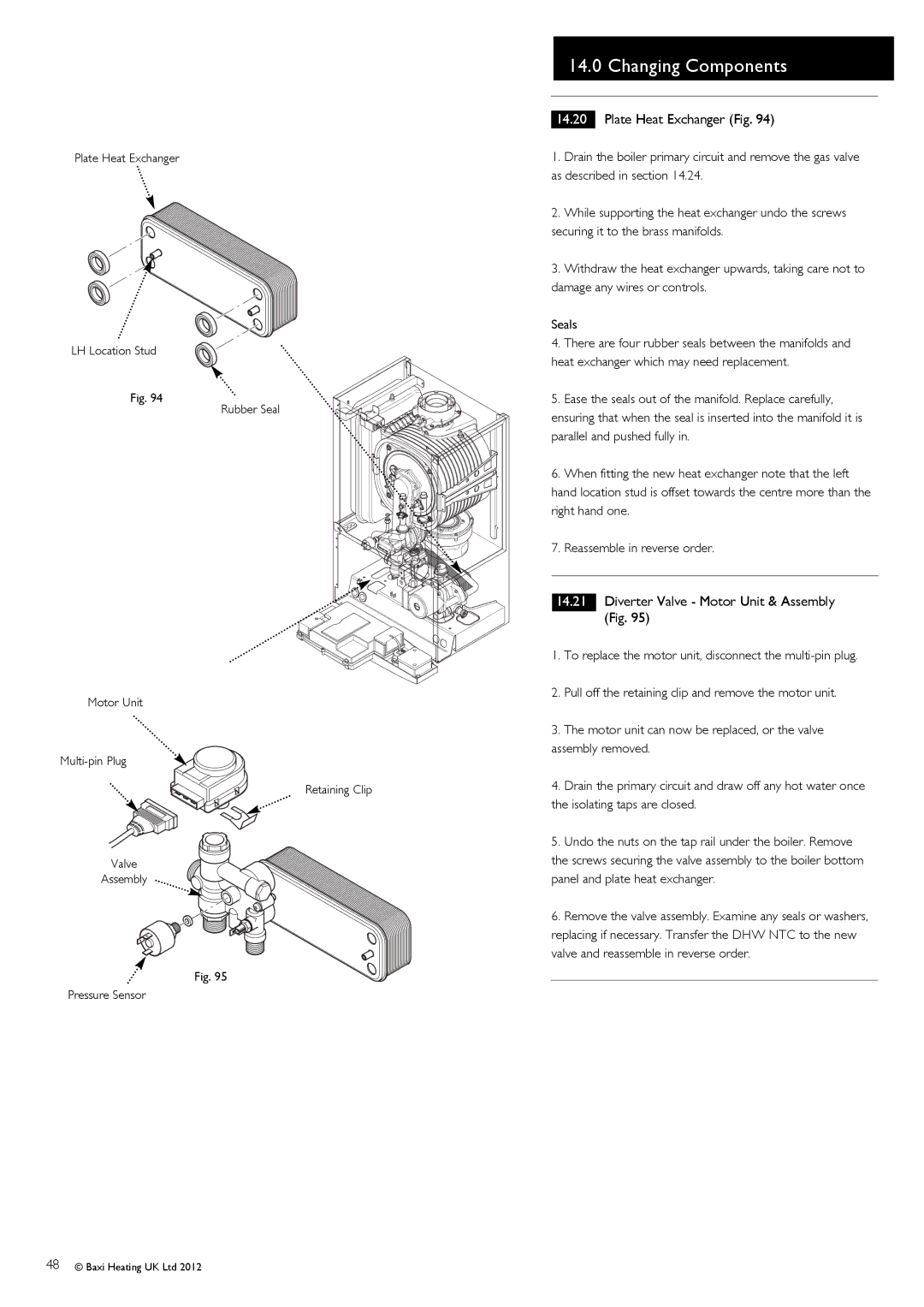

The Baxi Potterton range employs a heat exchanger system designed to maximize heat transfer and minimize energy waste. This sophisticated technology ensures that the boiler operates at peak efficiency, providing ample heating for homes even in the coldest months. The use of a durable, high-quality heat exchanger material contributes to the longevity of the unit, reducing the need for frequent repairs or replacements.

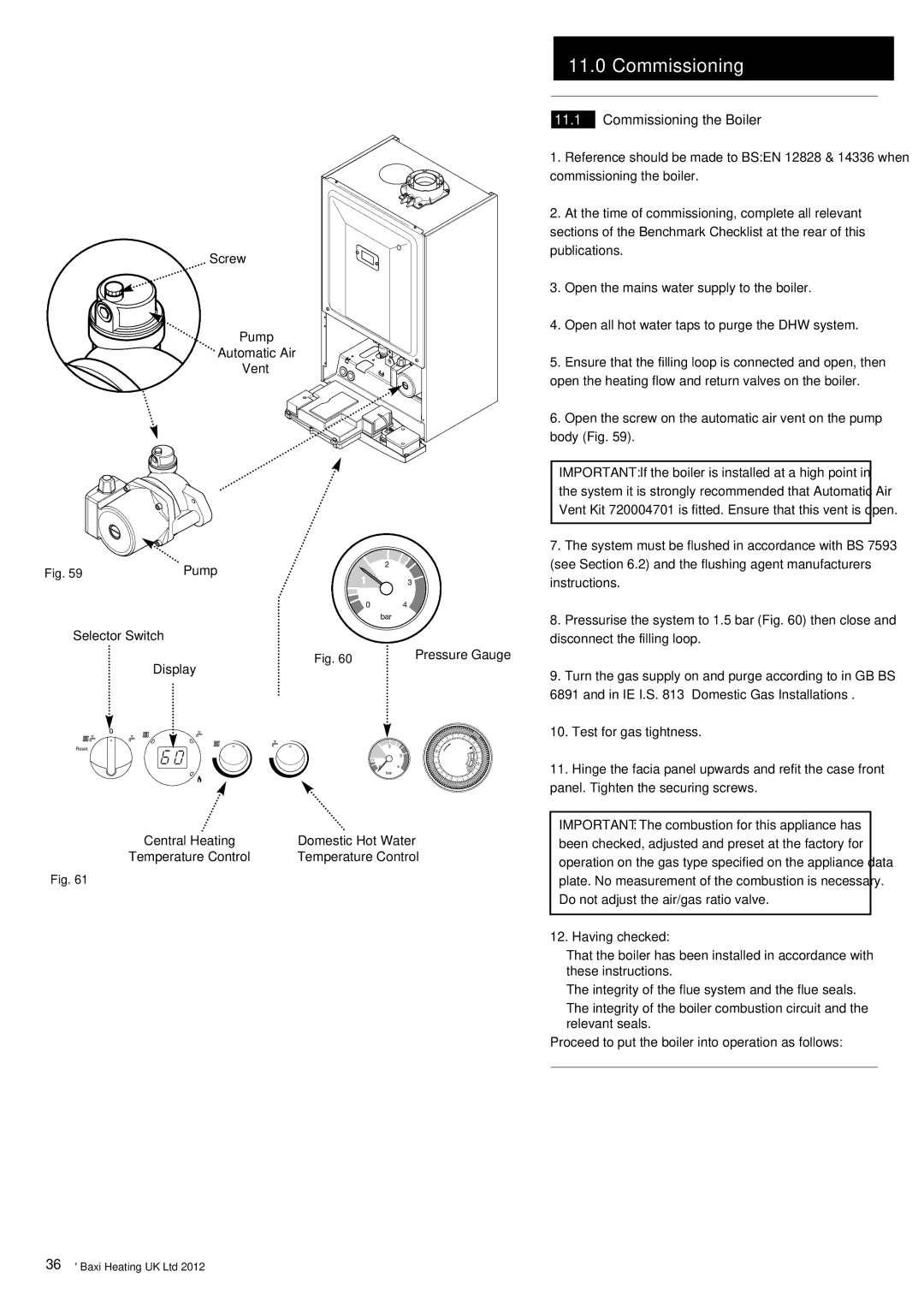

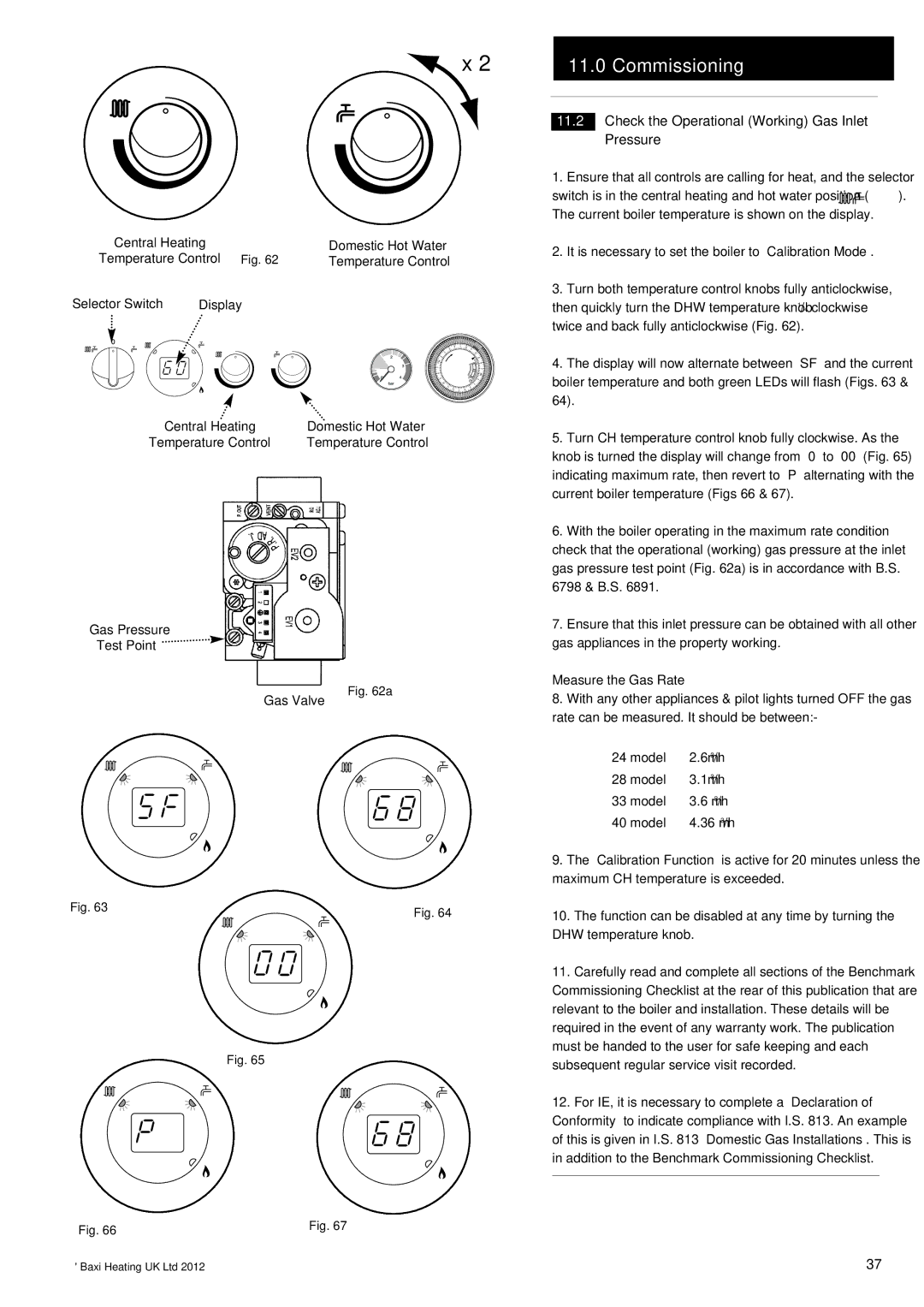

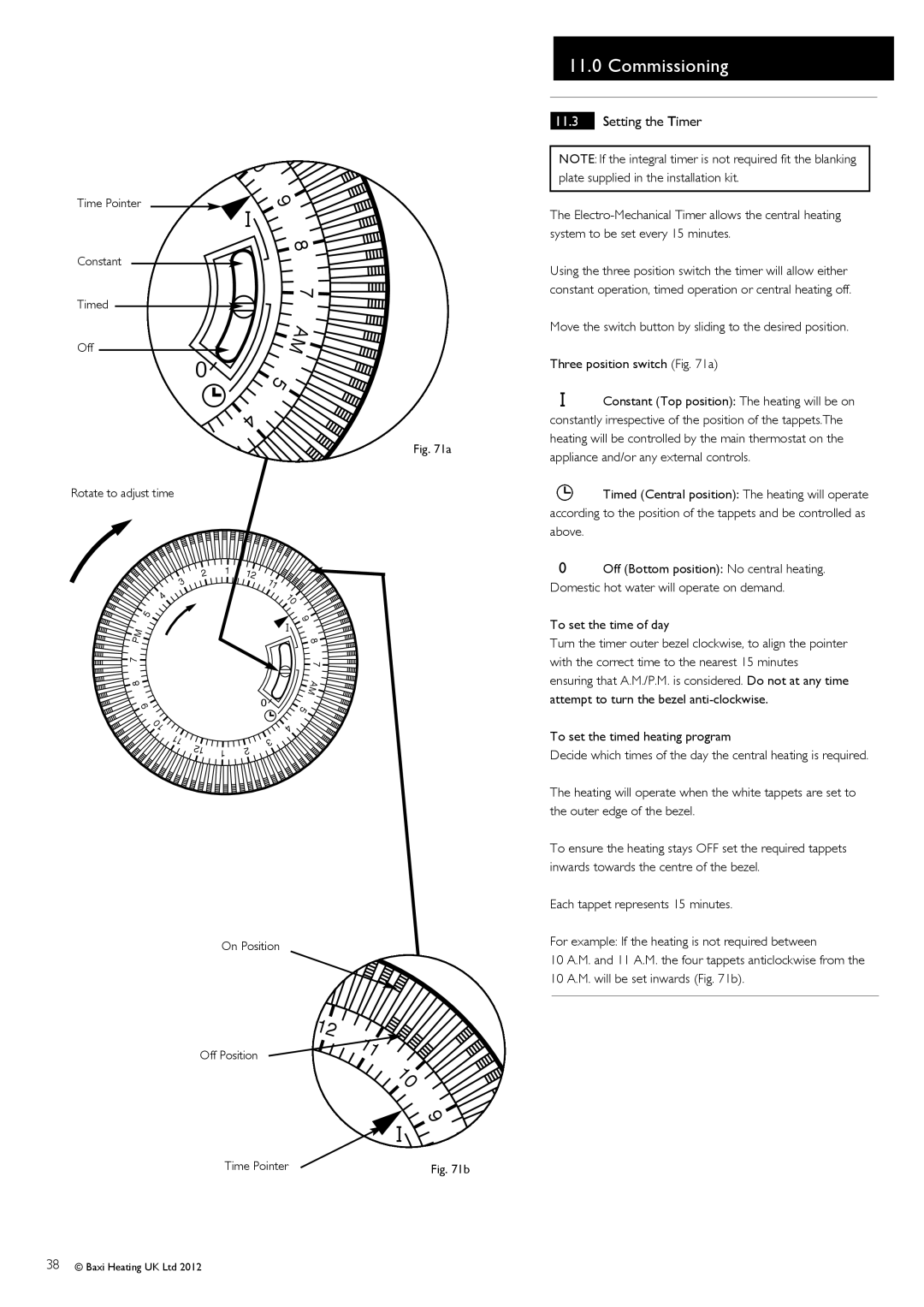

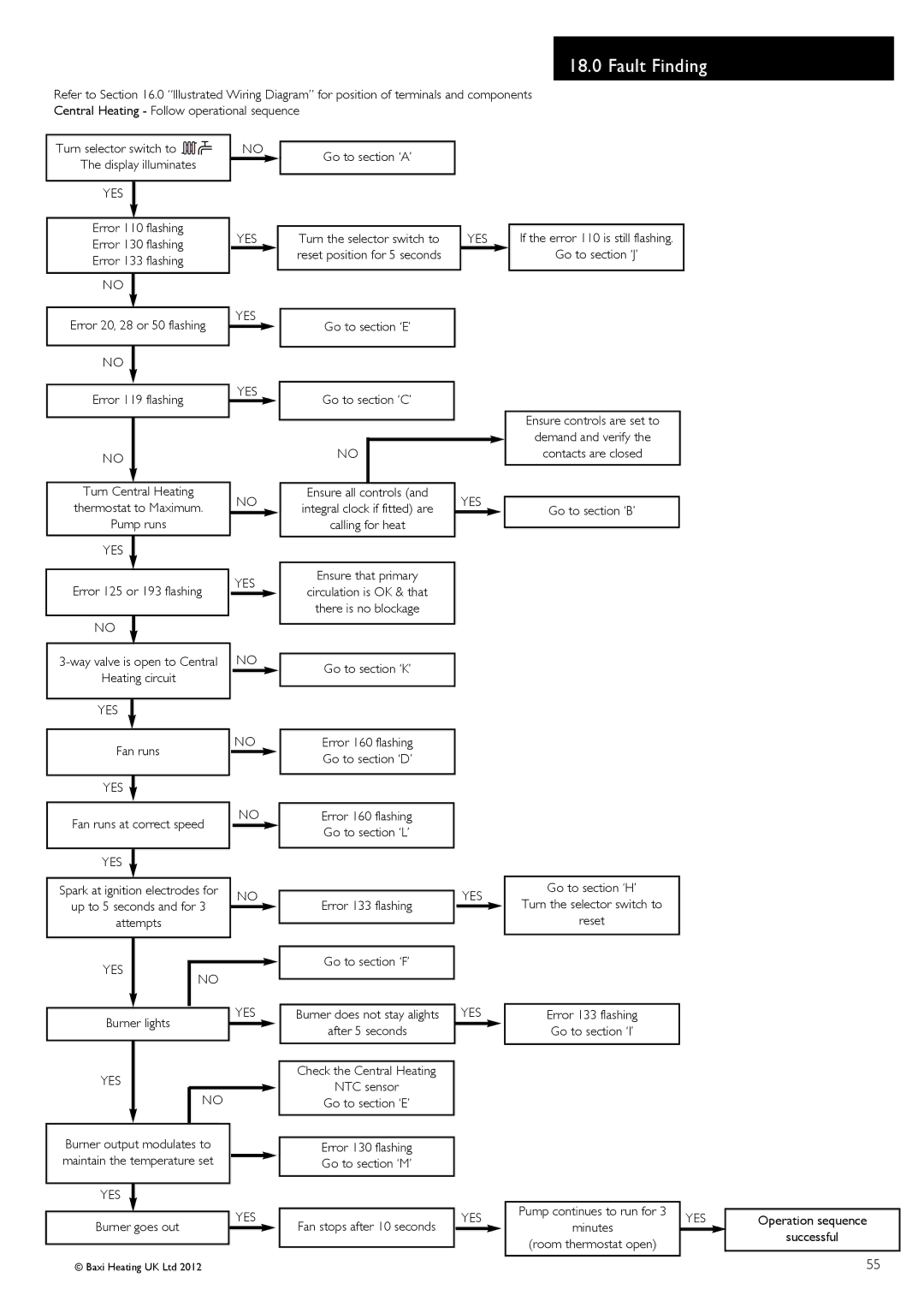

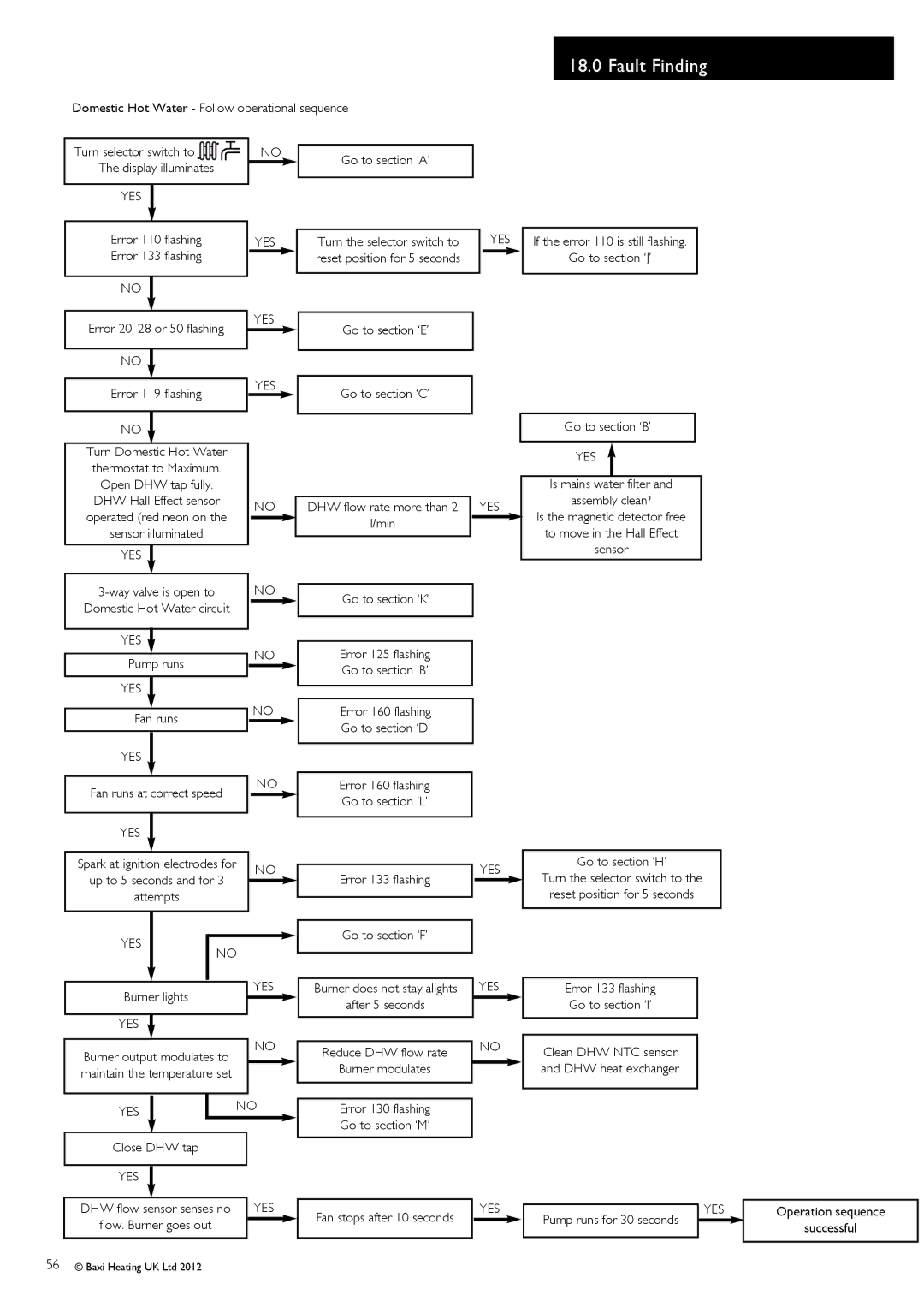

Ease of use is another hallmark of the 47-393 series. With an intuitive digital display, users can effortlessly monitor and adjust settings as required. The controls are straightforward, allowing for quick temperature adjustments, system diagnostics, and alerts, creating a hassle-free experience for homeowners.

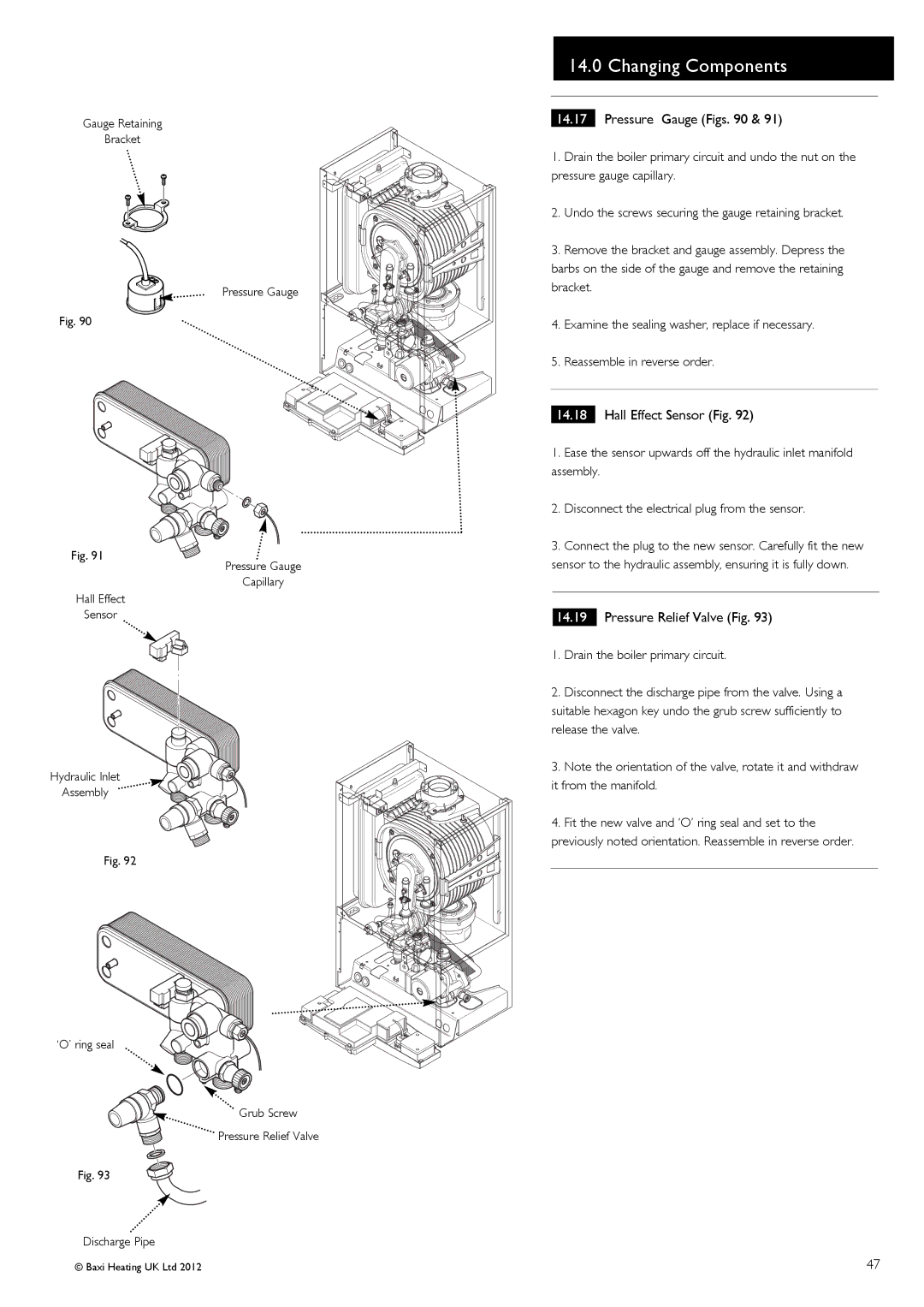

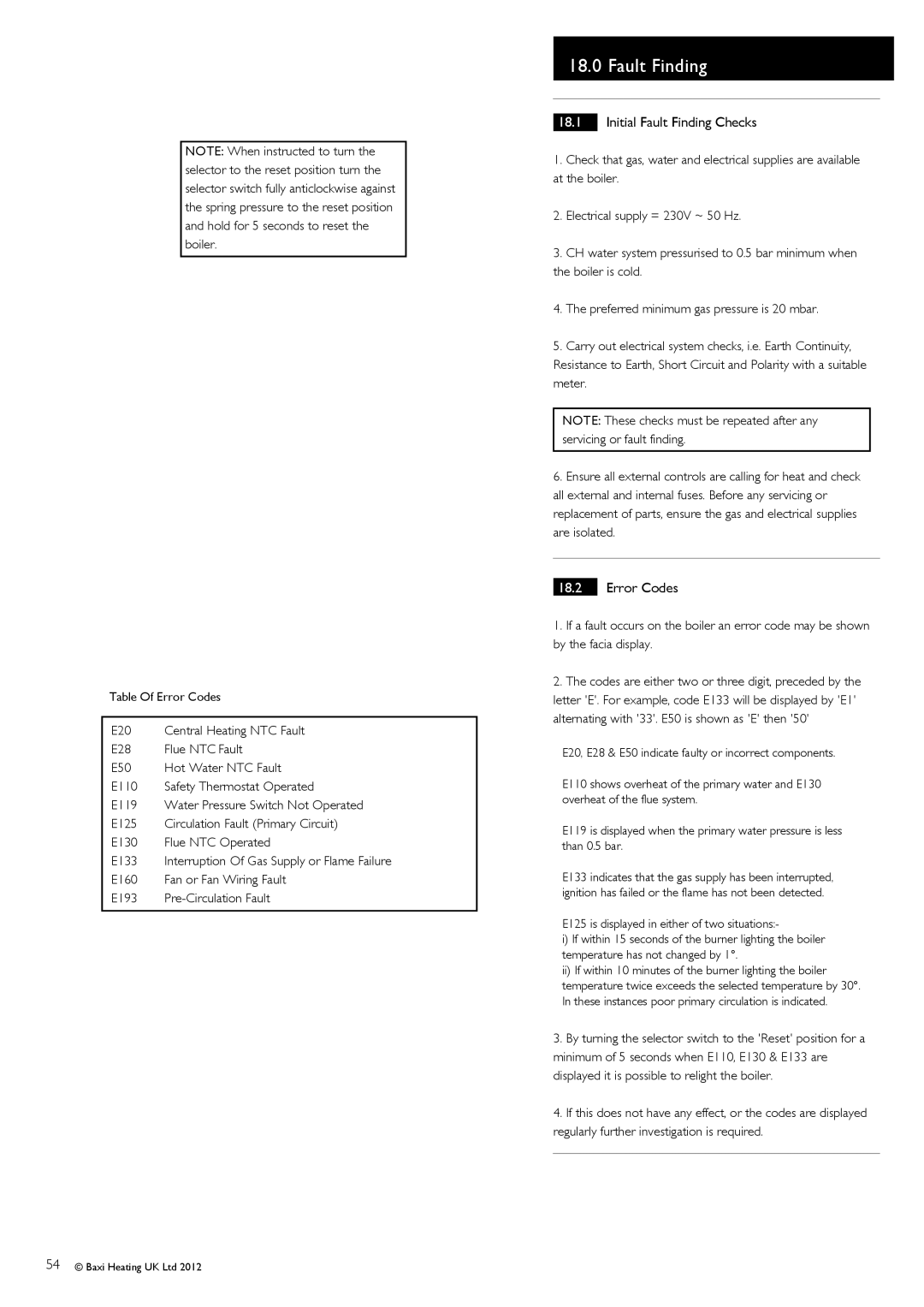

Safety features are inherent in these models, including built-in safeguards against overheating and pressure fluctuations. The automatic shut-off mechanism ensures that the boiler operates within safe parameters, providing peace of mind to users.

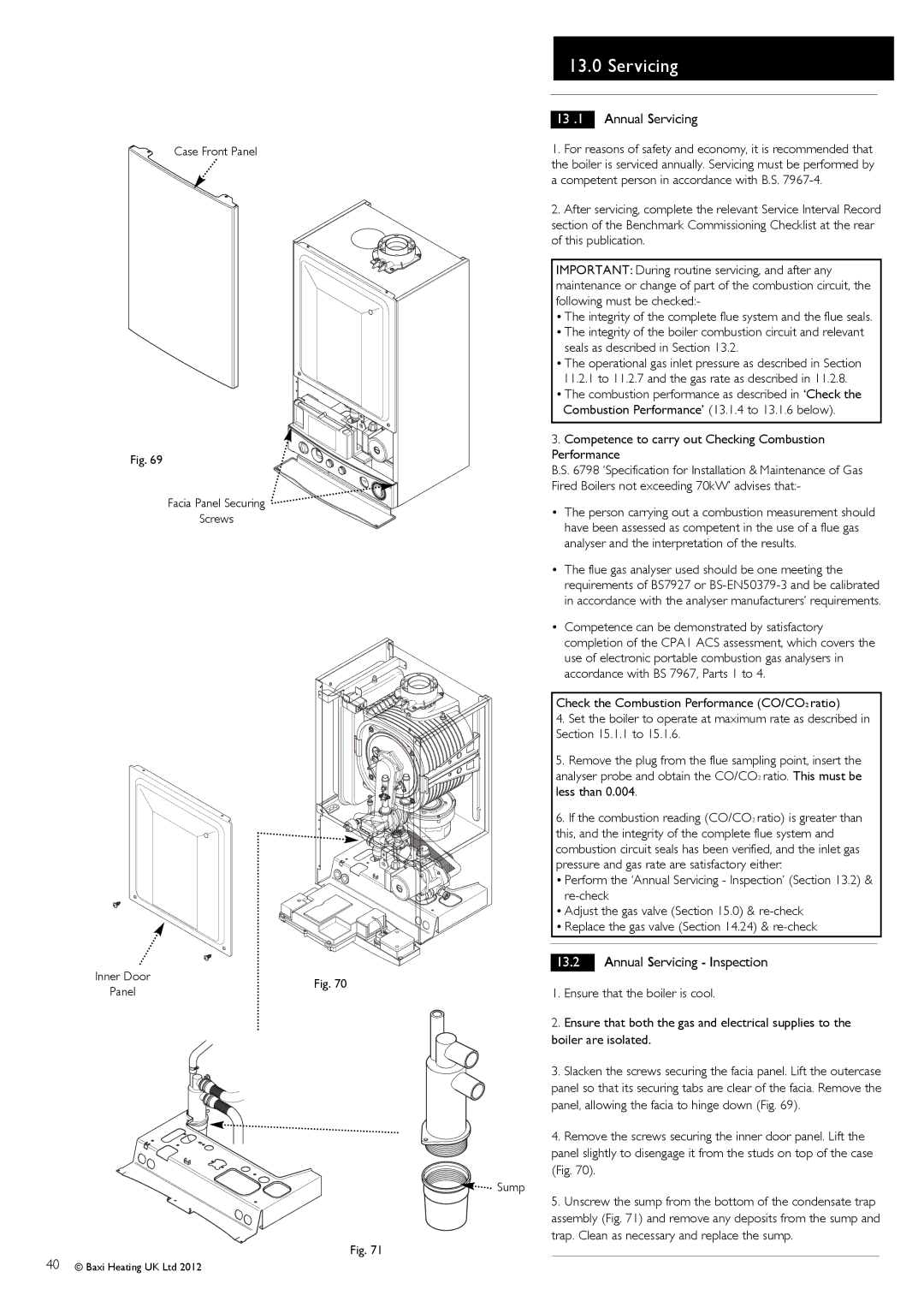

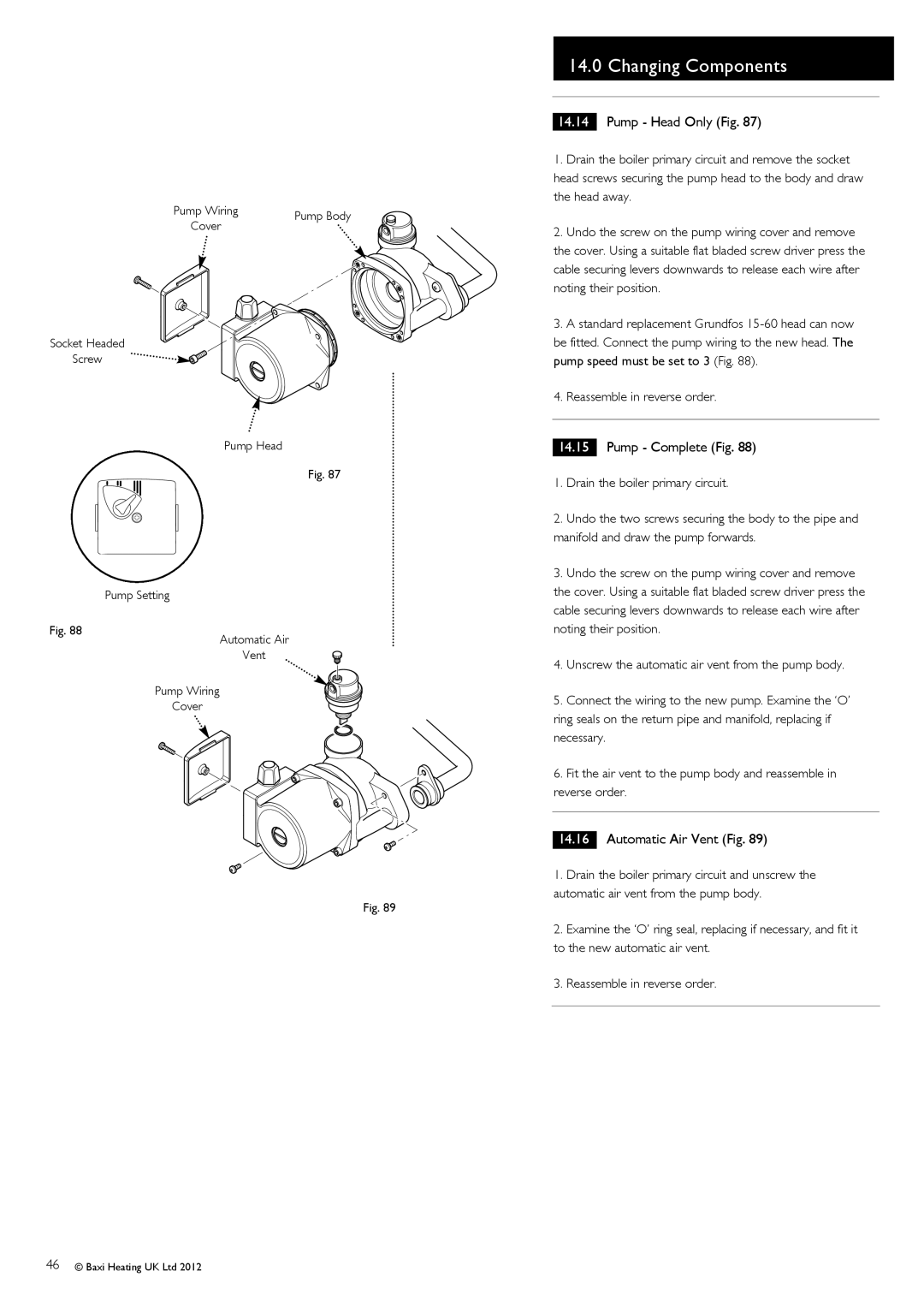

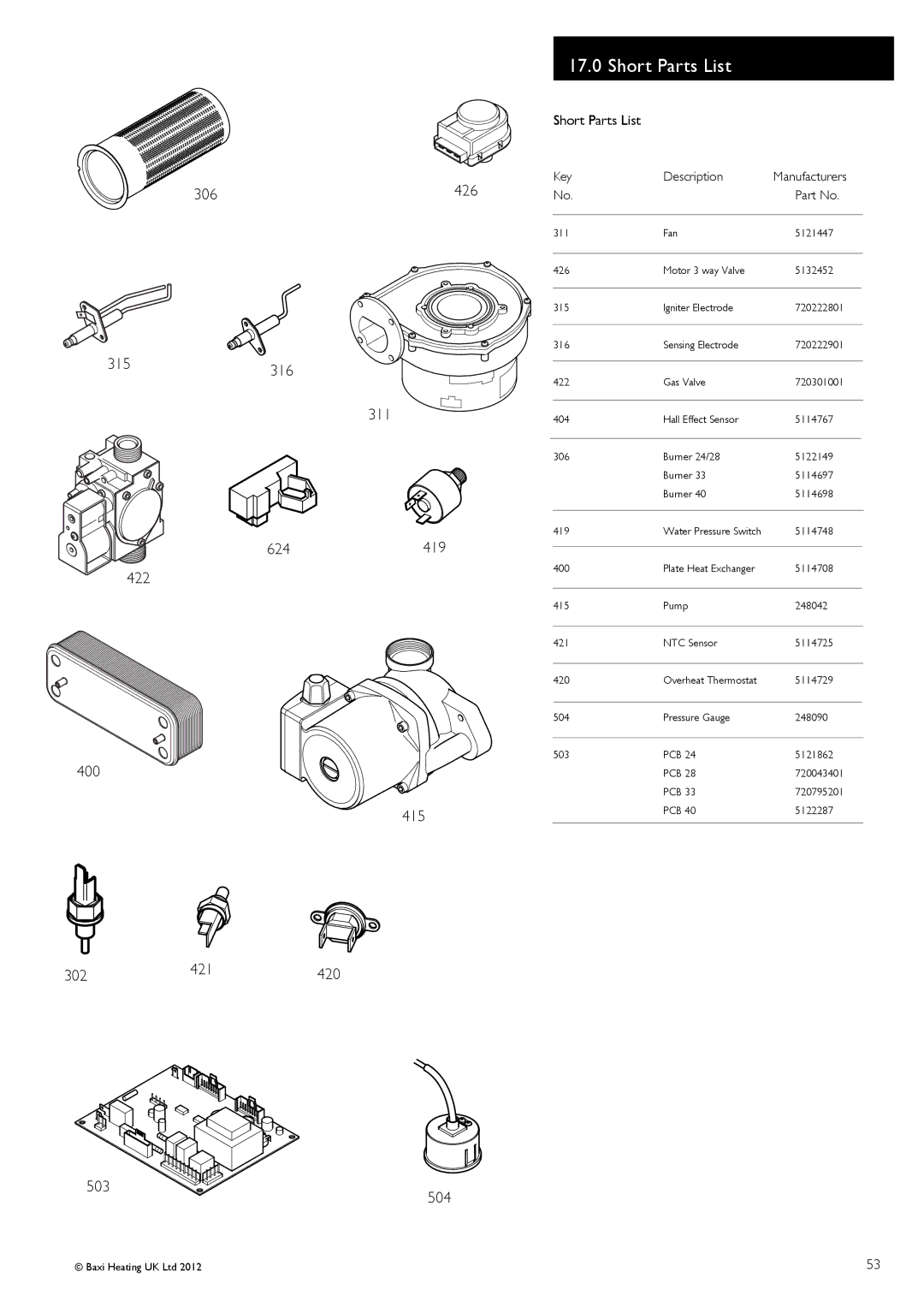

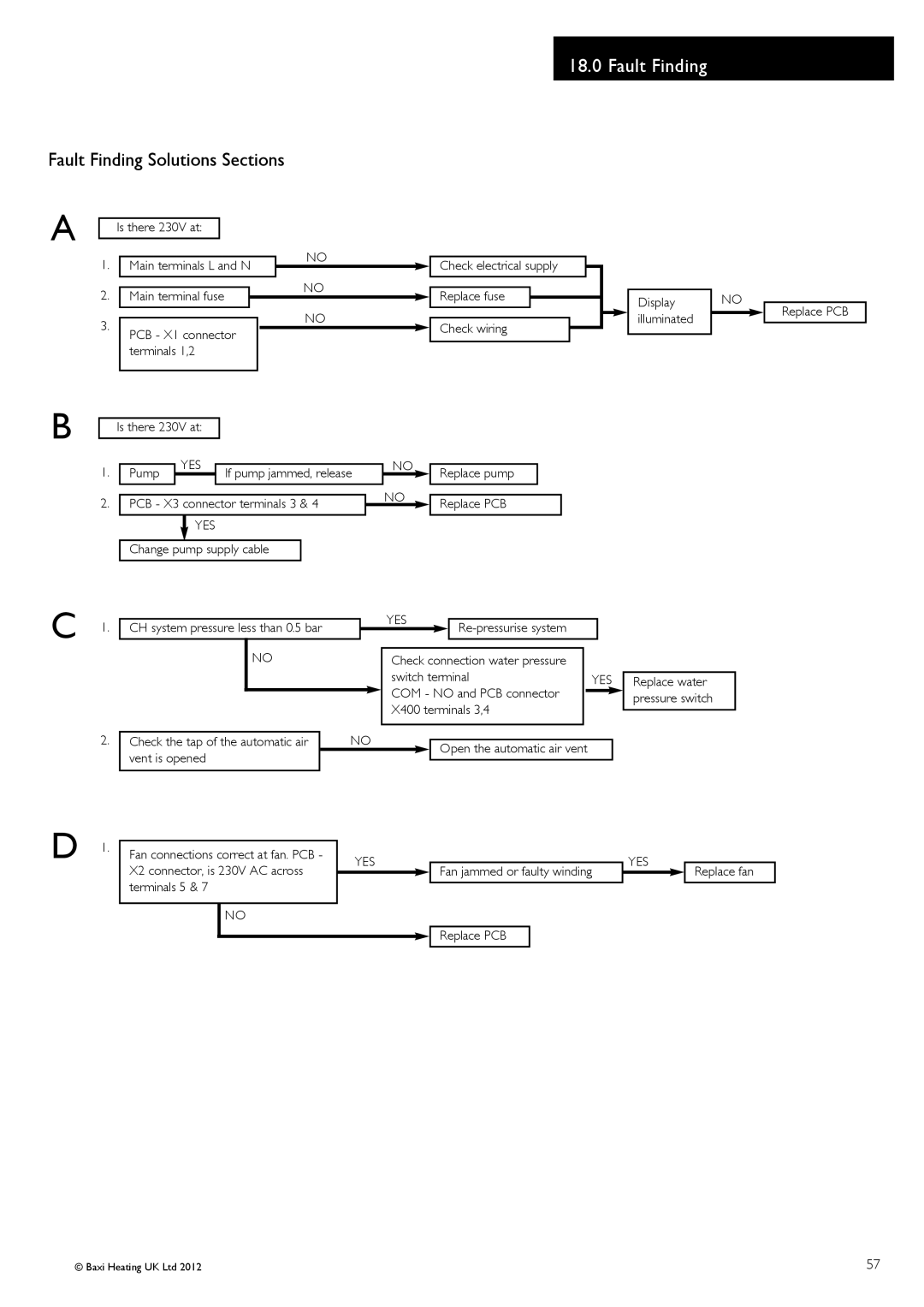

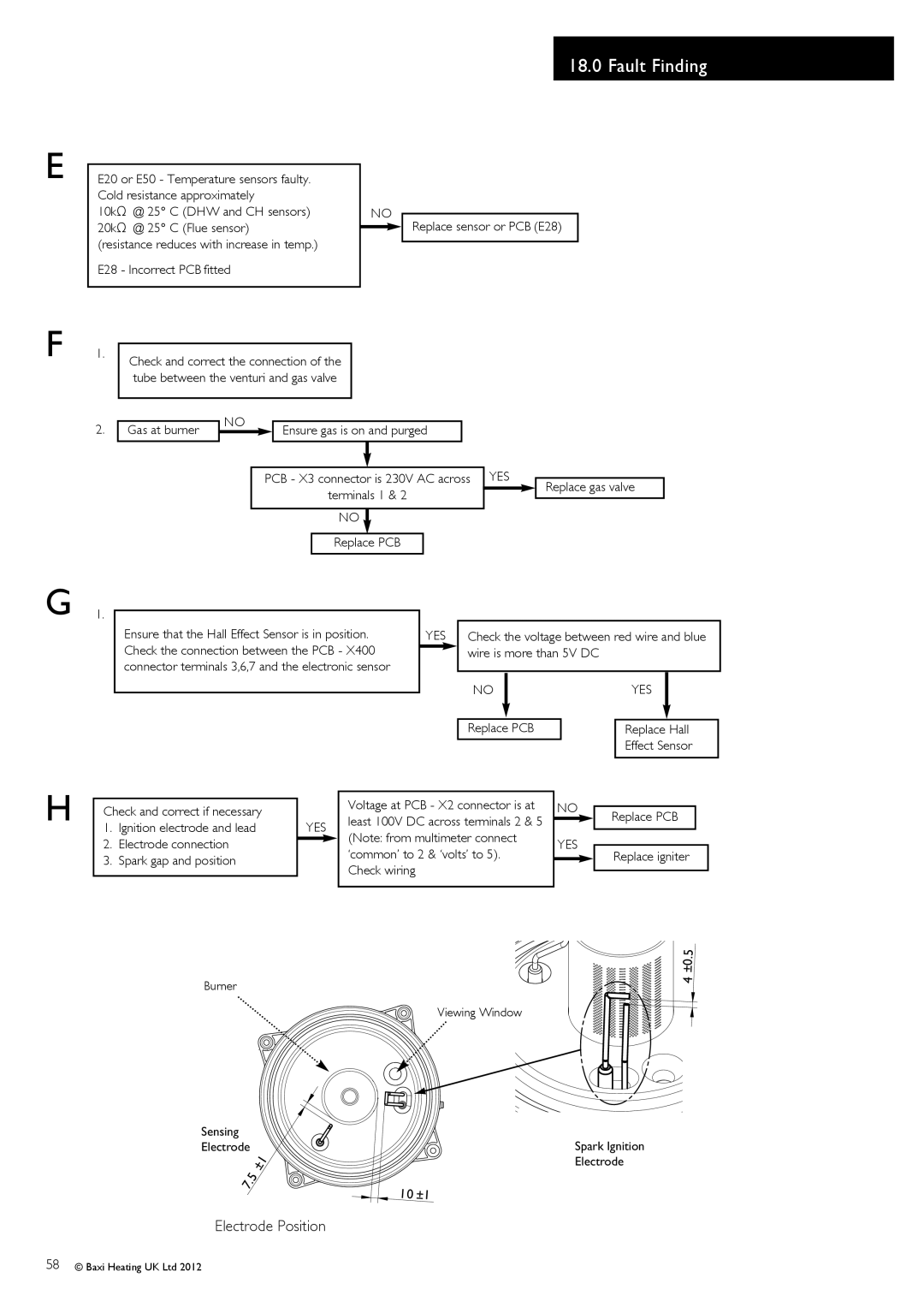

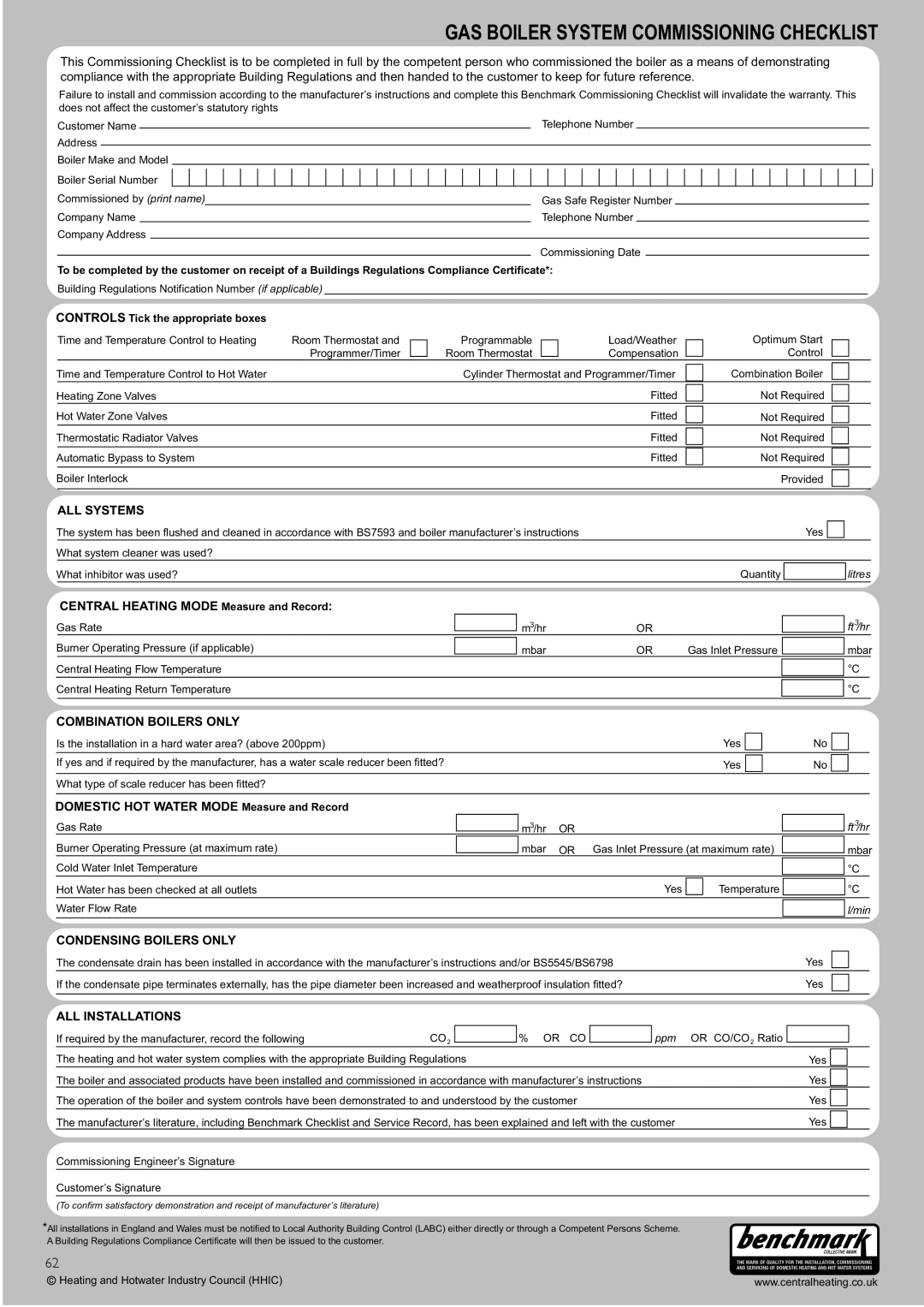

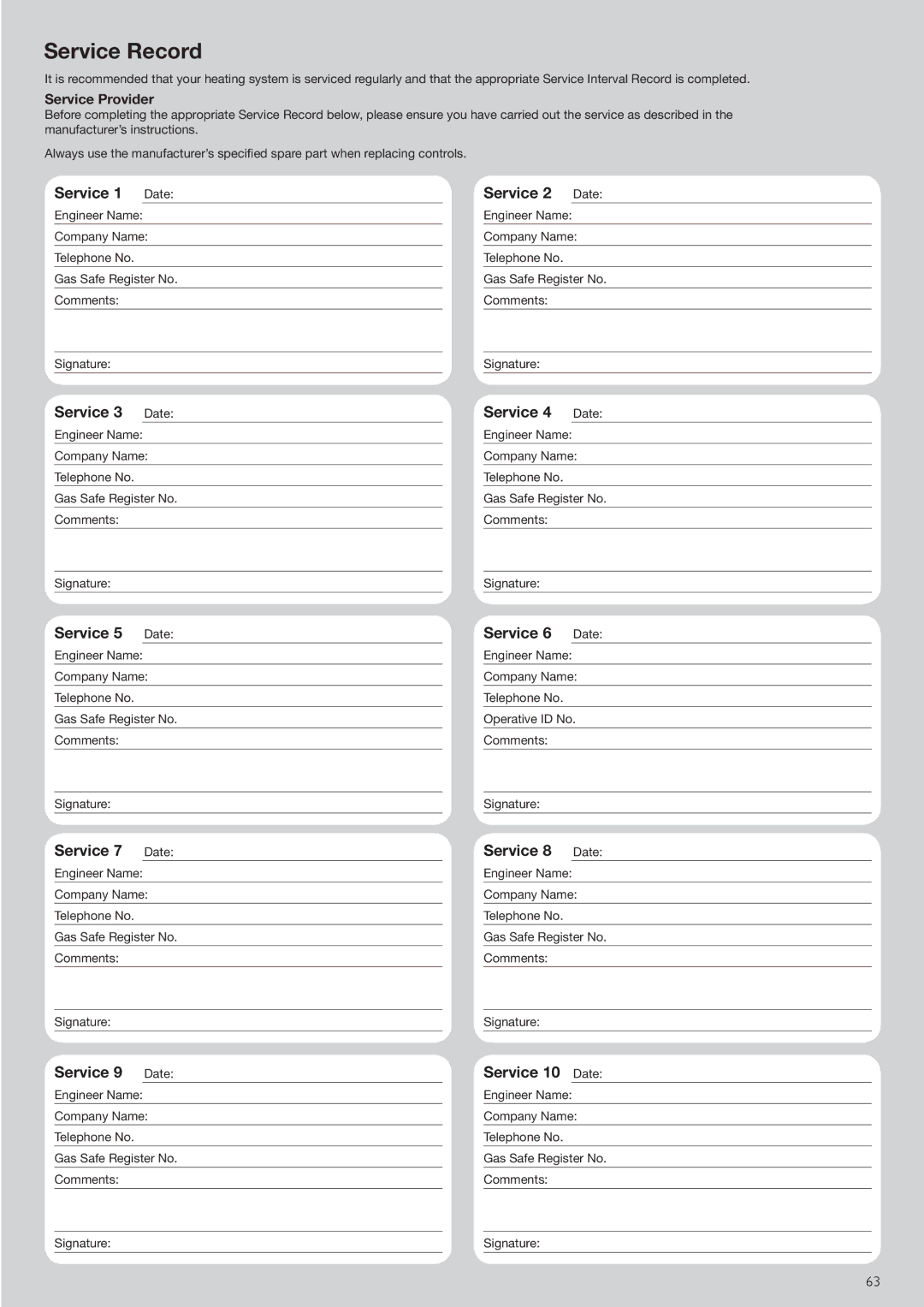

Furthermore, maintenance is simplified with the easy access design. The accessible components make it straightforward for service technicians to perform routine checks and repairs. Regular maintenance is essential for sustaining high performance and extending the lifespan of the boiler.

In conclusion, the Baxi Potterton 47-393-42, 47-393-39, 47-393-41, and 47-393-40 models represent a blend of efficiency, safety, and convenience. Their advanced technologies and features not only enhance the user experience but also contribute to more sustainable heating solutions for homes. Investing in one of these advanced boilers ensures reliable performance, lower energy costs, and a commitment to environmental responsibility.