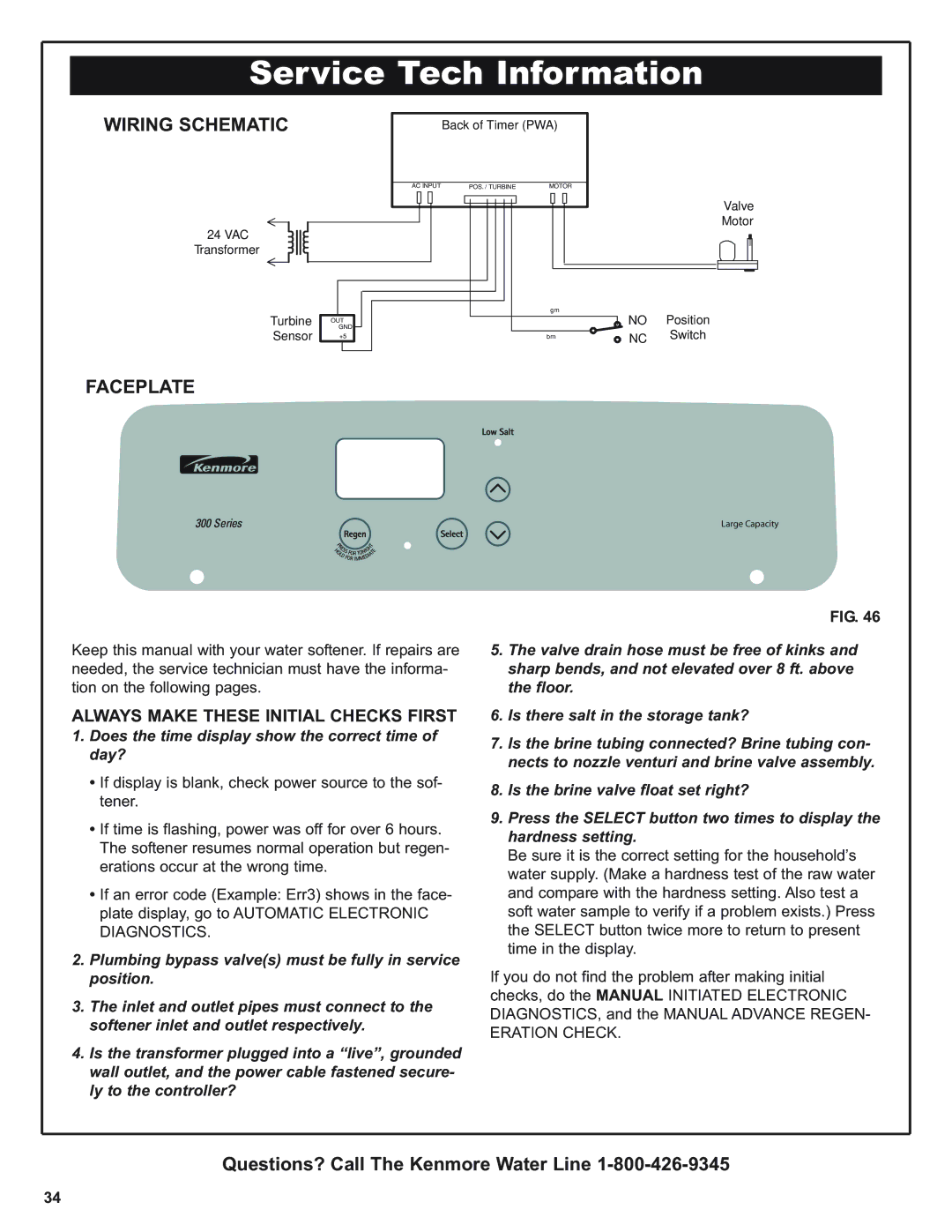

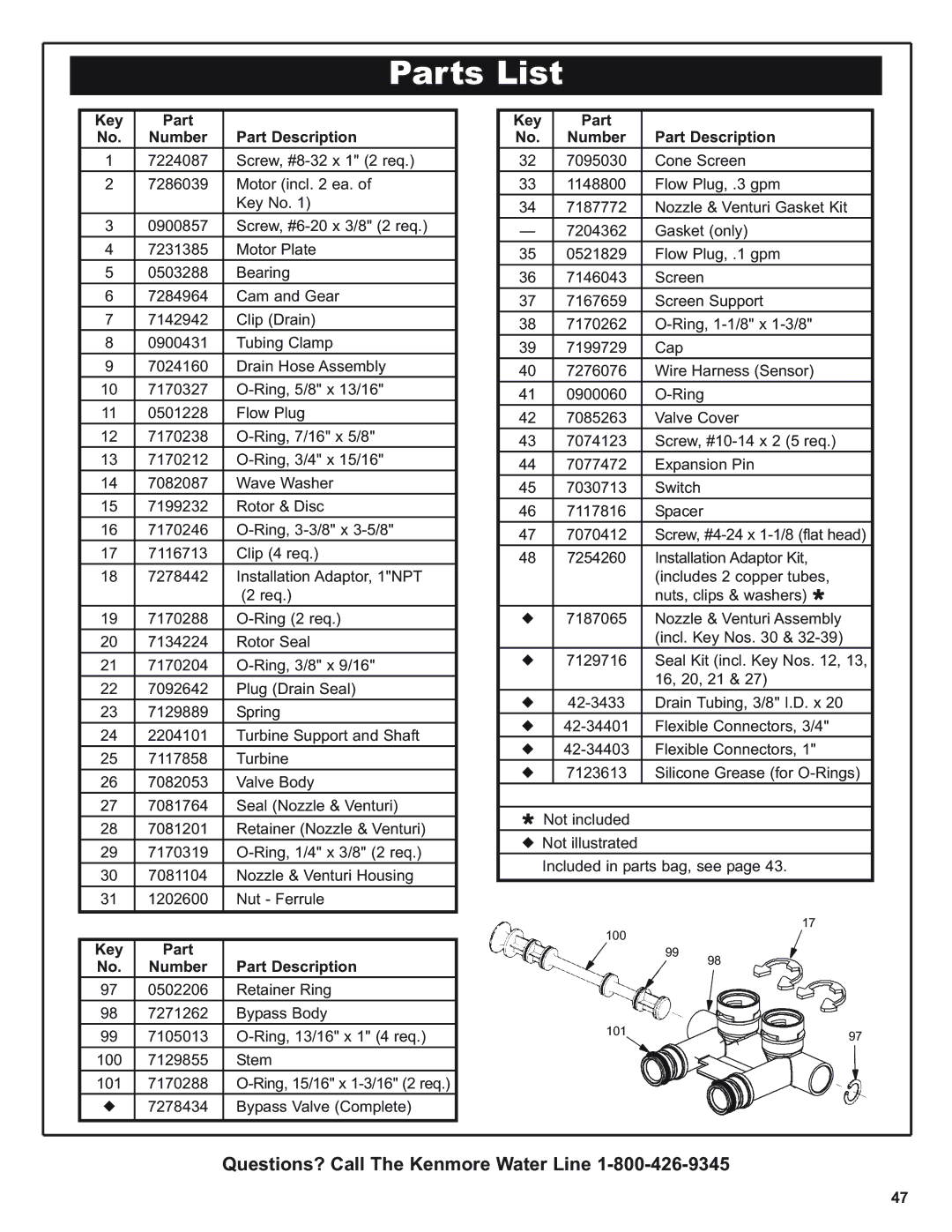

Service Tech Information

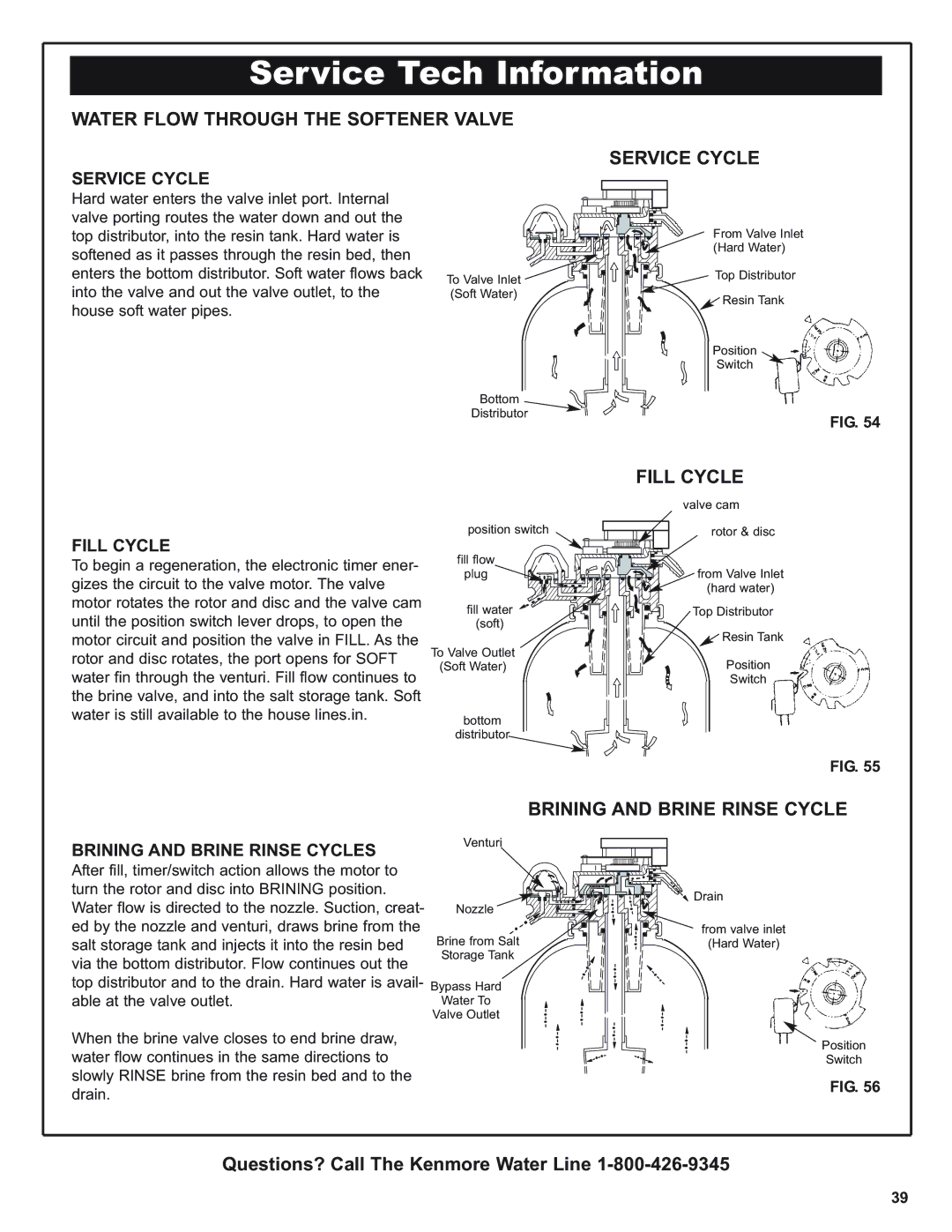

The faceplate timer (PWA) computer has a |

| ||||

nostic function for the electrical system, except put |

| ||||

power and water meter. The computer monitors elec- |

| ||||

tronic components and circuits for correct operation. If a |

| ||||

malfunction occurs, an error code appears in the face- |

| ||||

plate display. |

|

|

|

| FIG. 47 |

|

|

|

|

| |

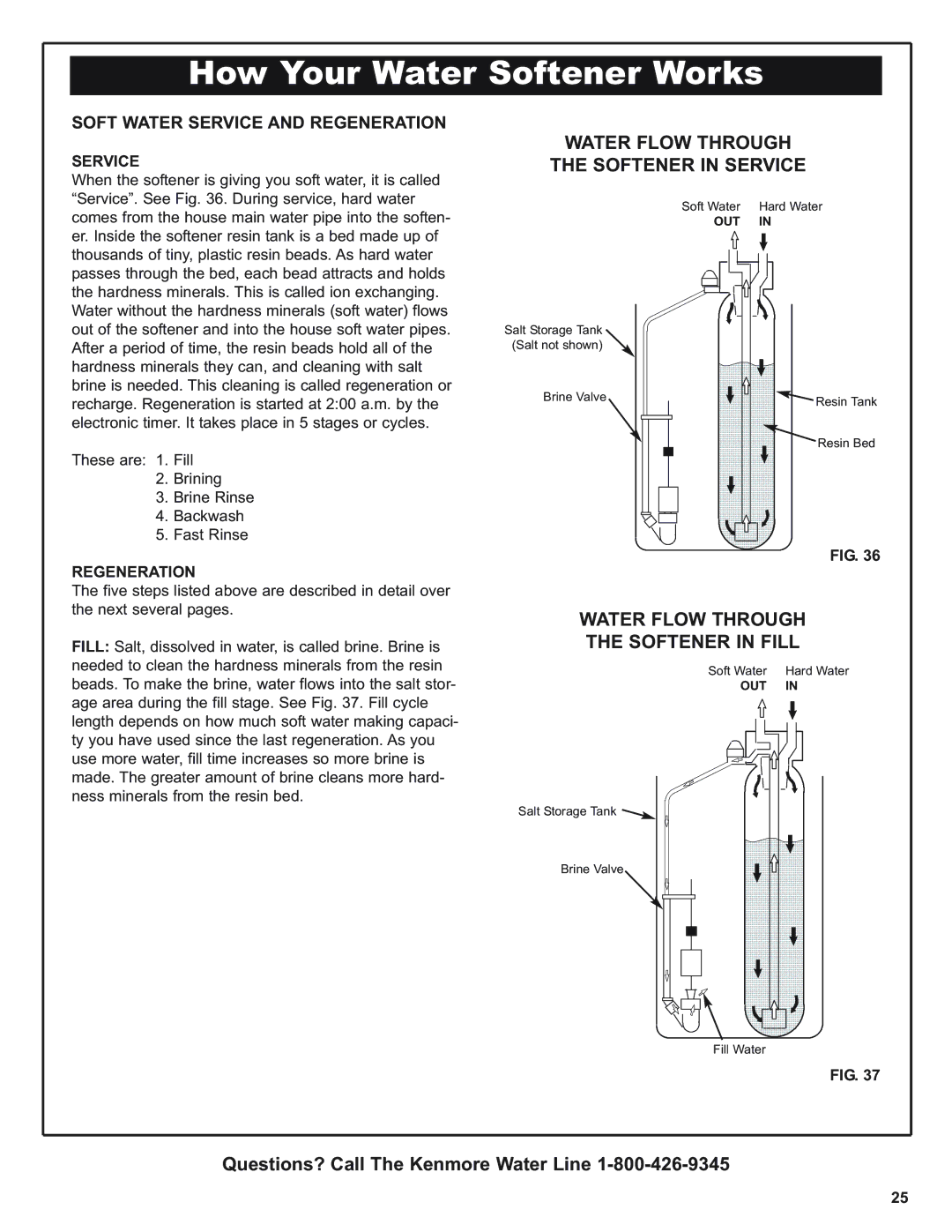

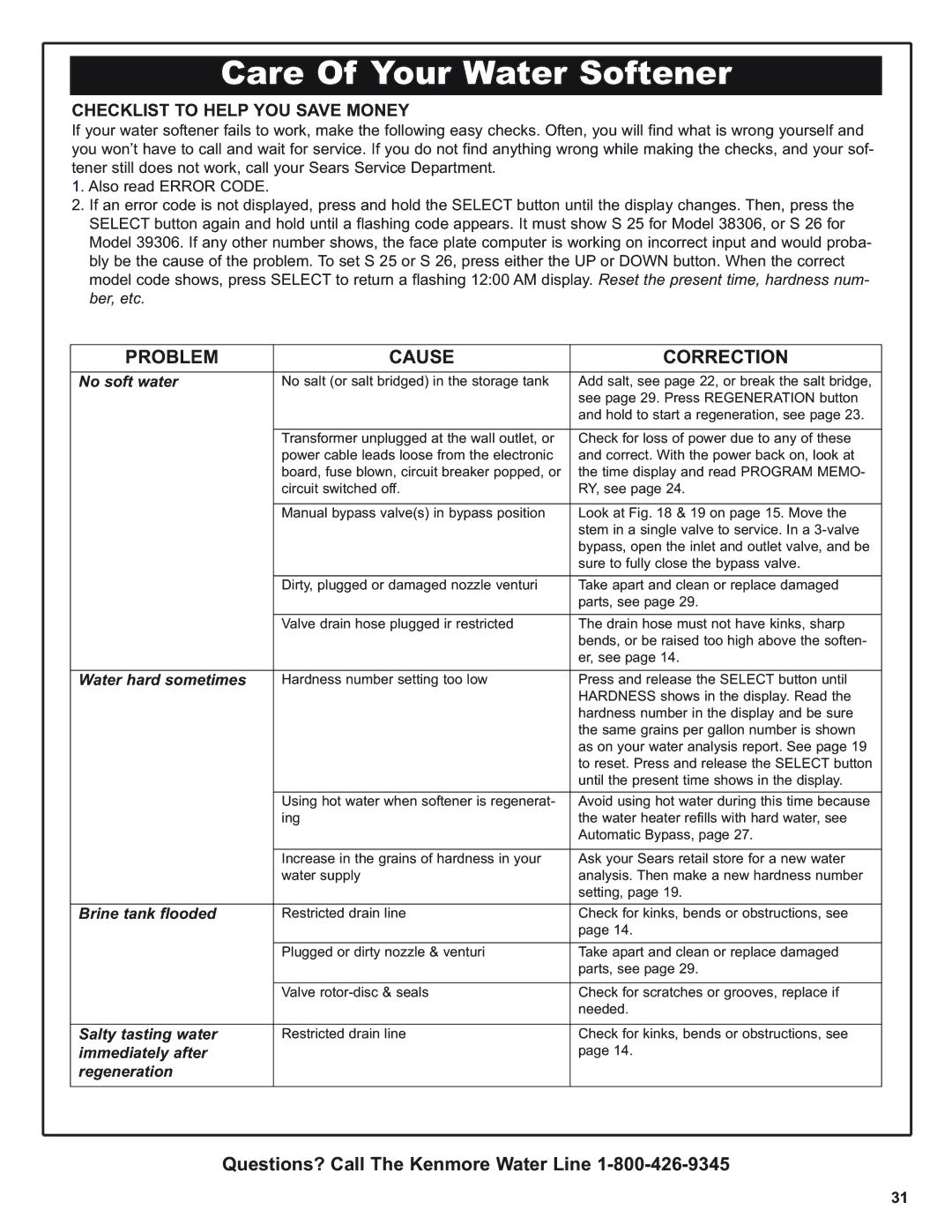

The chart below shows the error codes that could |

| ||||

appear, and the possible defects for each code. |

| ||||

|

|

|

|

|

|

|

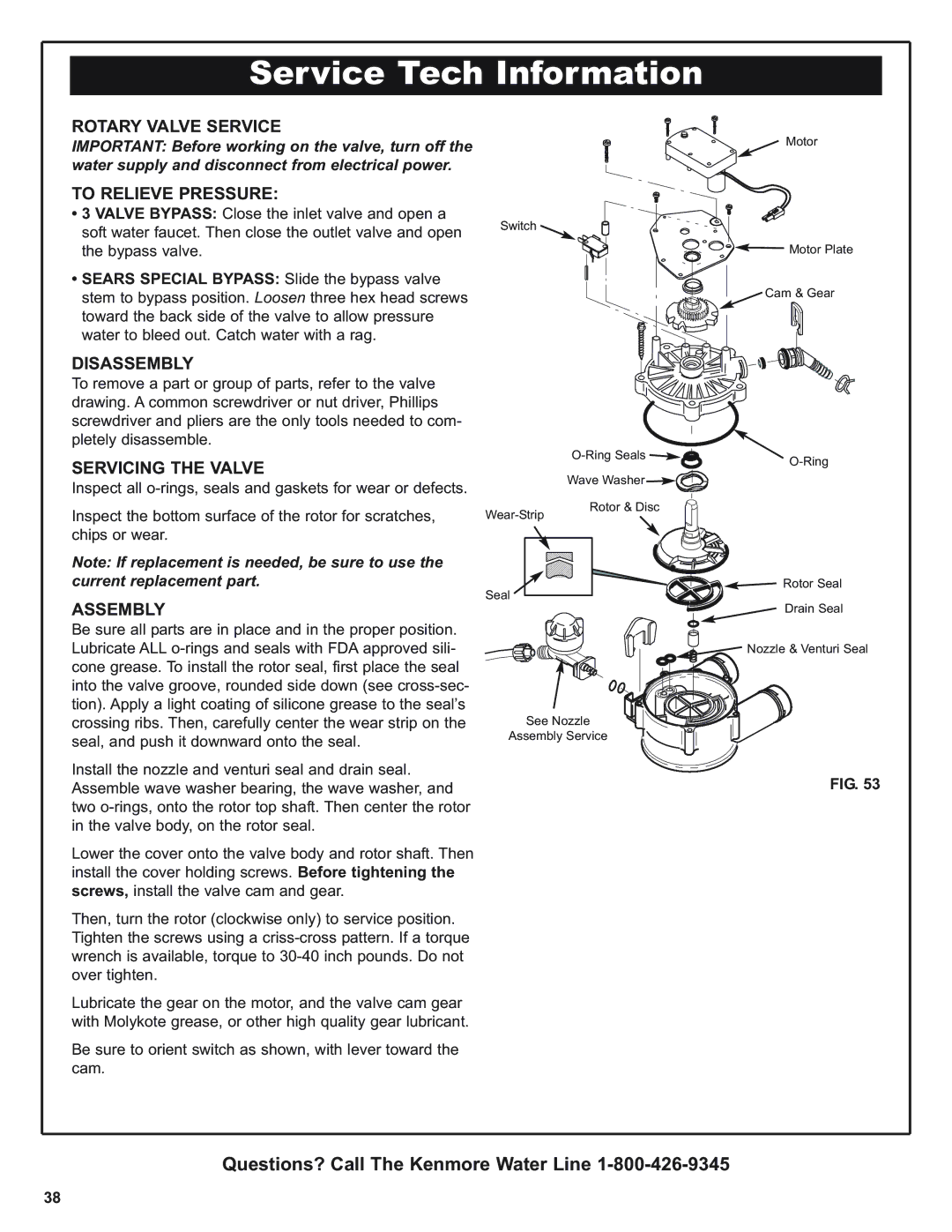

| POSSIBLE DEFECT |

| ||

|

|

|

|

|

|

CODE | MOST LIKELY |

|

|

| LESS LIKELY |

|

|

| |||

|

|

|

|

|

|

Err1, Err3, Err4 | motor inoperative / wiring harness or connection to switch / position switch . valve defect causing high torque |

| |||

|

|

| |||

Err5 | faceplate timer (PWA) |

| |||

|

|

|

|

|

|

While an error code appears in the display, all face plate buttons are inoperable except the SELECT button. SELECT remains operational so the service person can make the MANUAL INITIATED ELECTRONIC DIAG- NOSTICS (below) to further isolate the defect, and check the water meter.

PROCEDURE FOR REMOVING ERROR CODE FROM FACEPLATE:

•Unplug transformer from outlet.

•Correct defect

•Plug in transformer.

•Wait for 8 minutes.

The error code will return if the defect was not corrected.

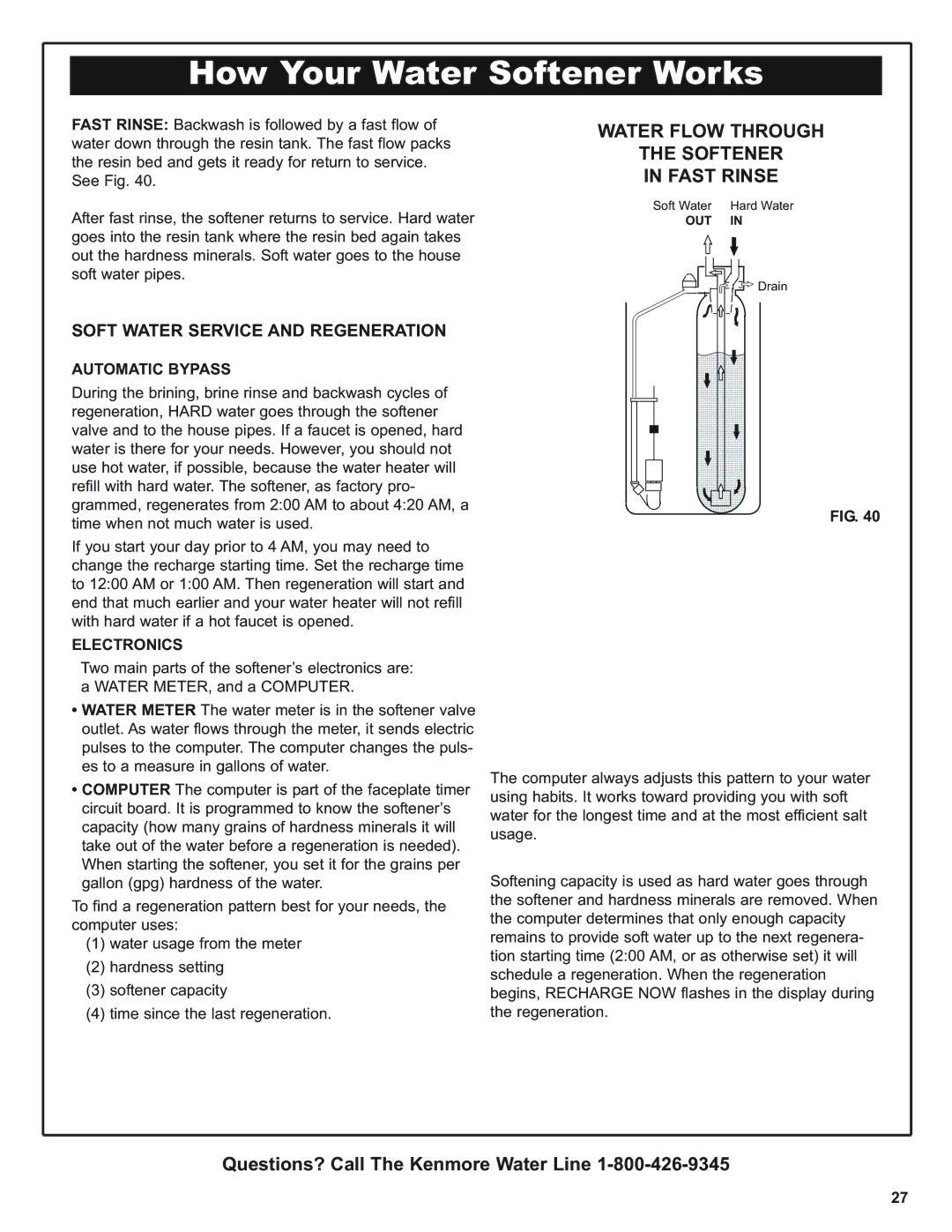

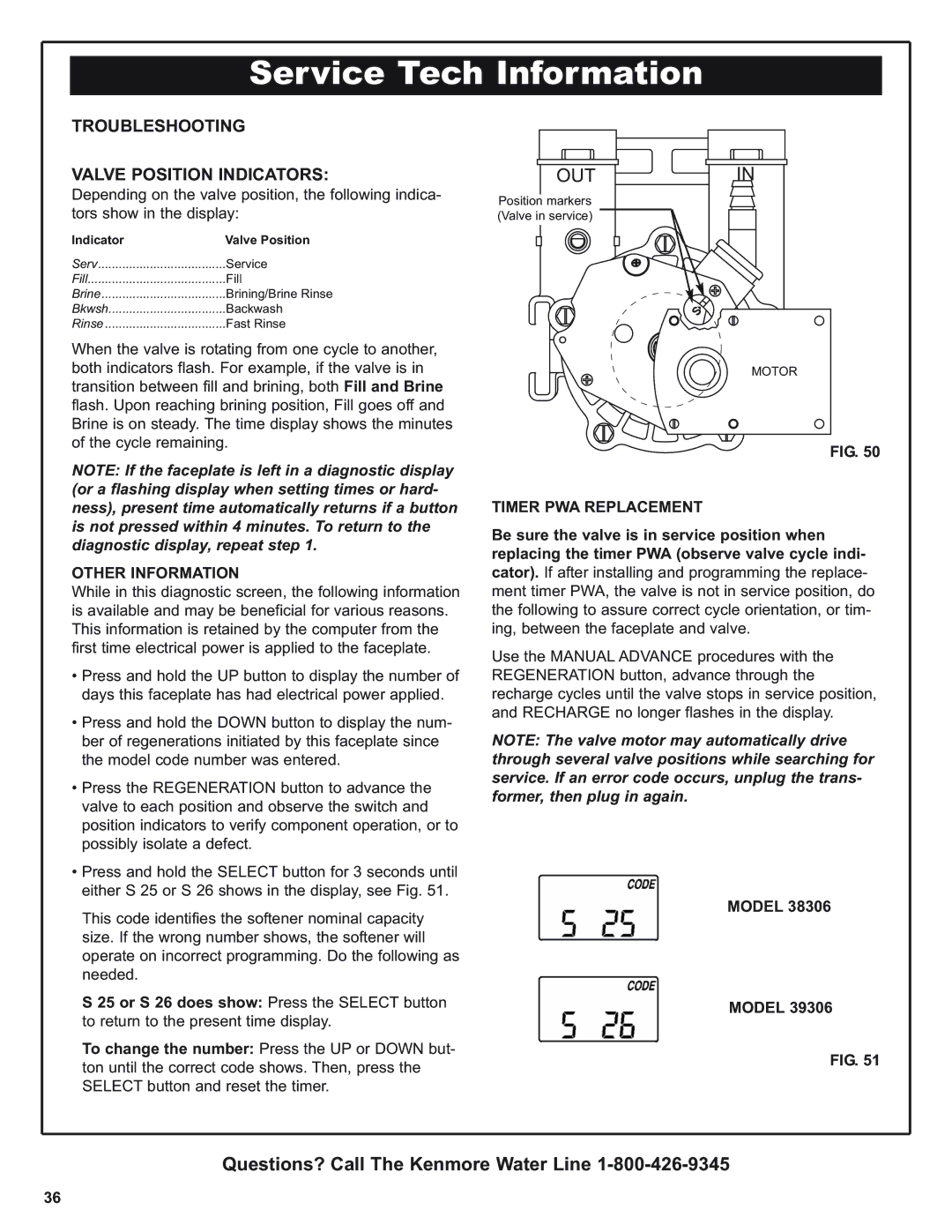

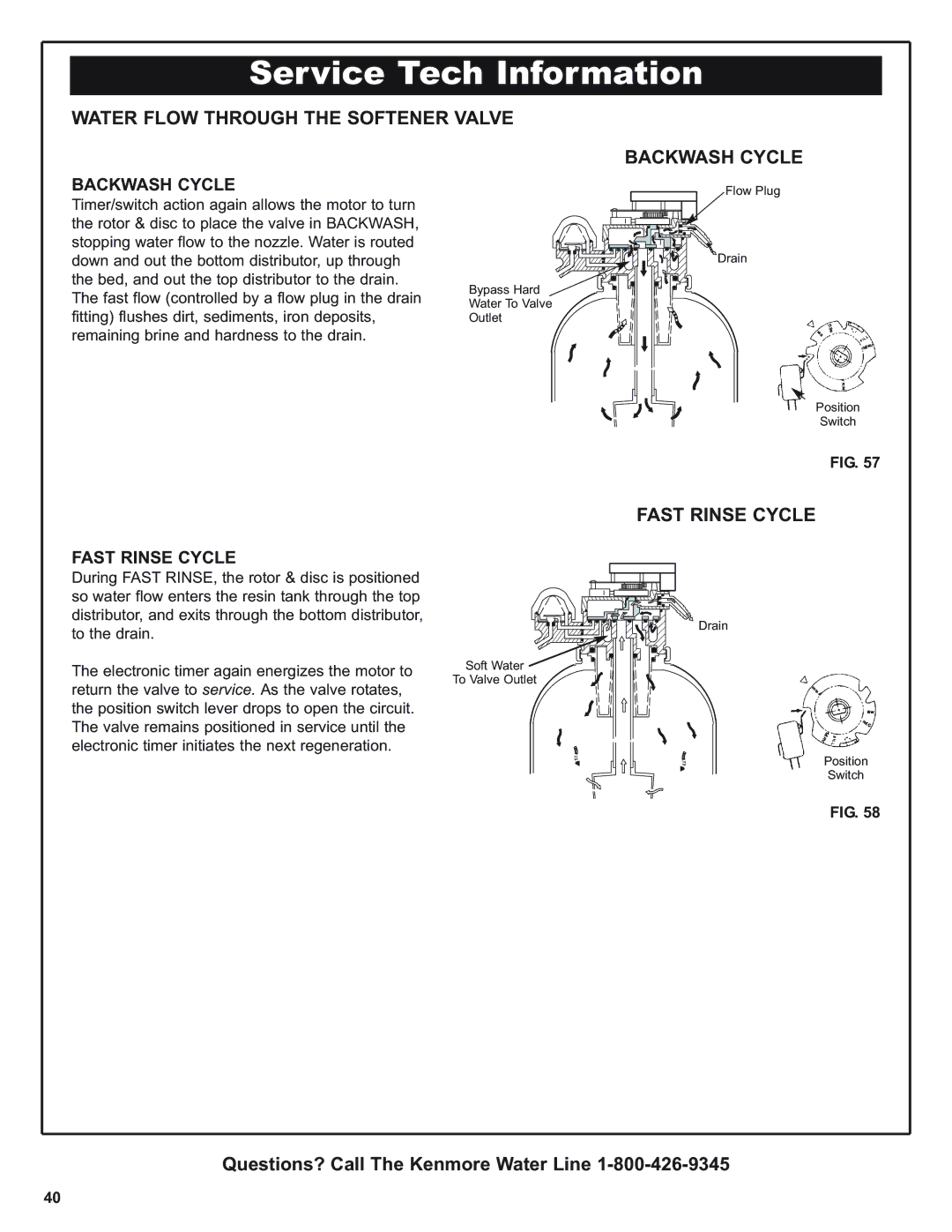

MANUAL INITIATED ELECTRONICS DIAGNOSTICS: To enter diagnostics, press the SELECT button until 000 - - shows in the display. See Fig. 48.

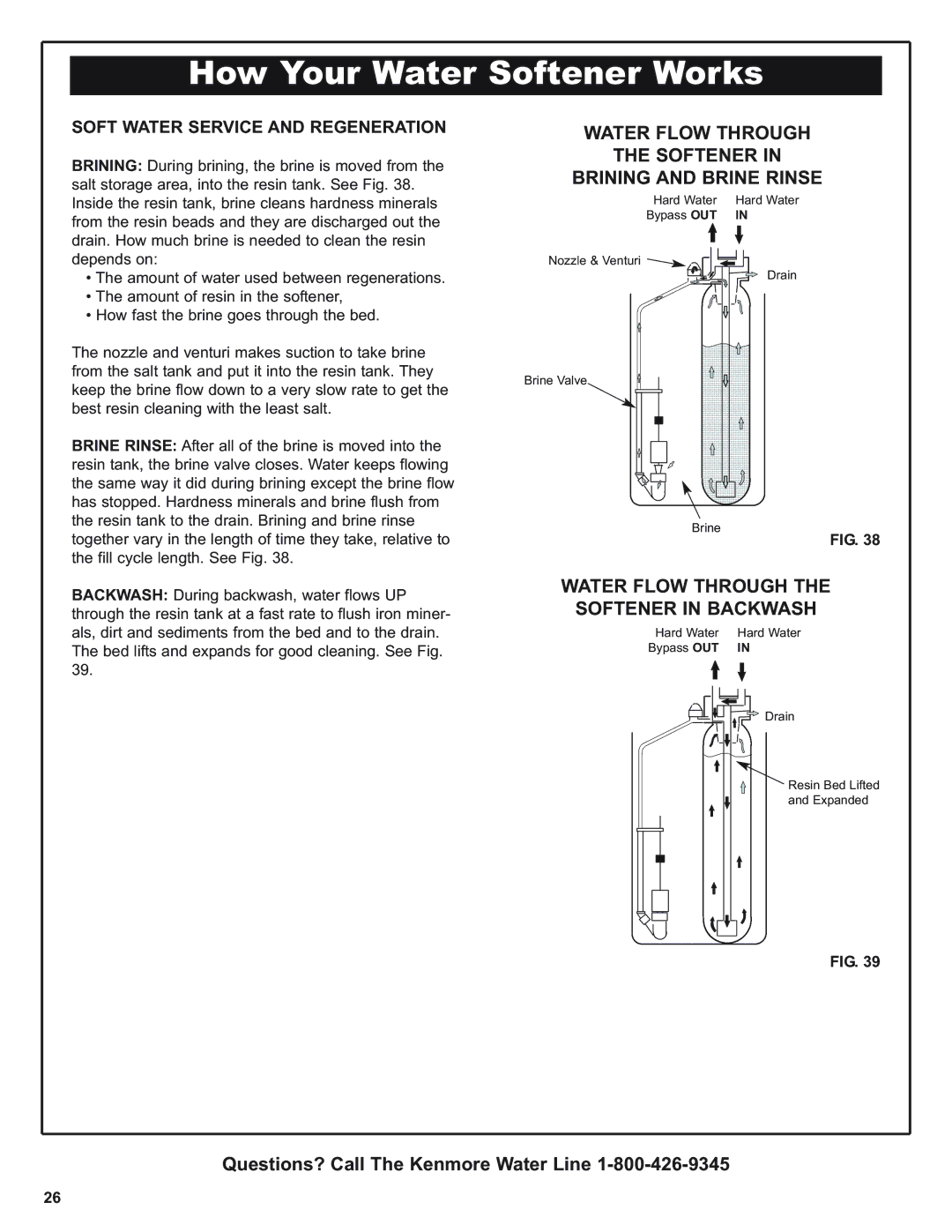

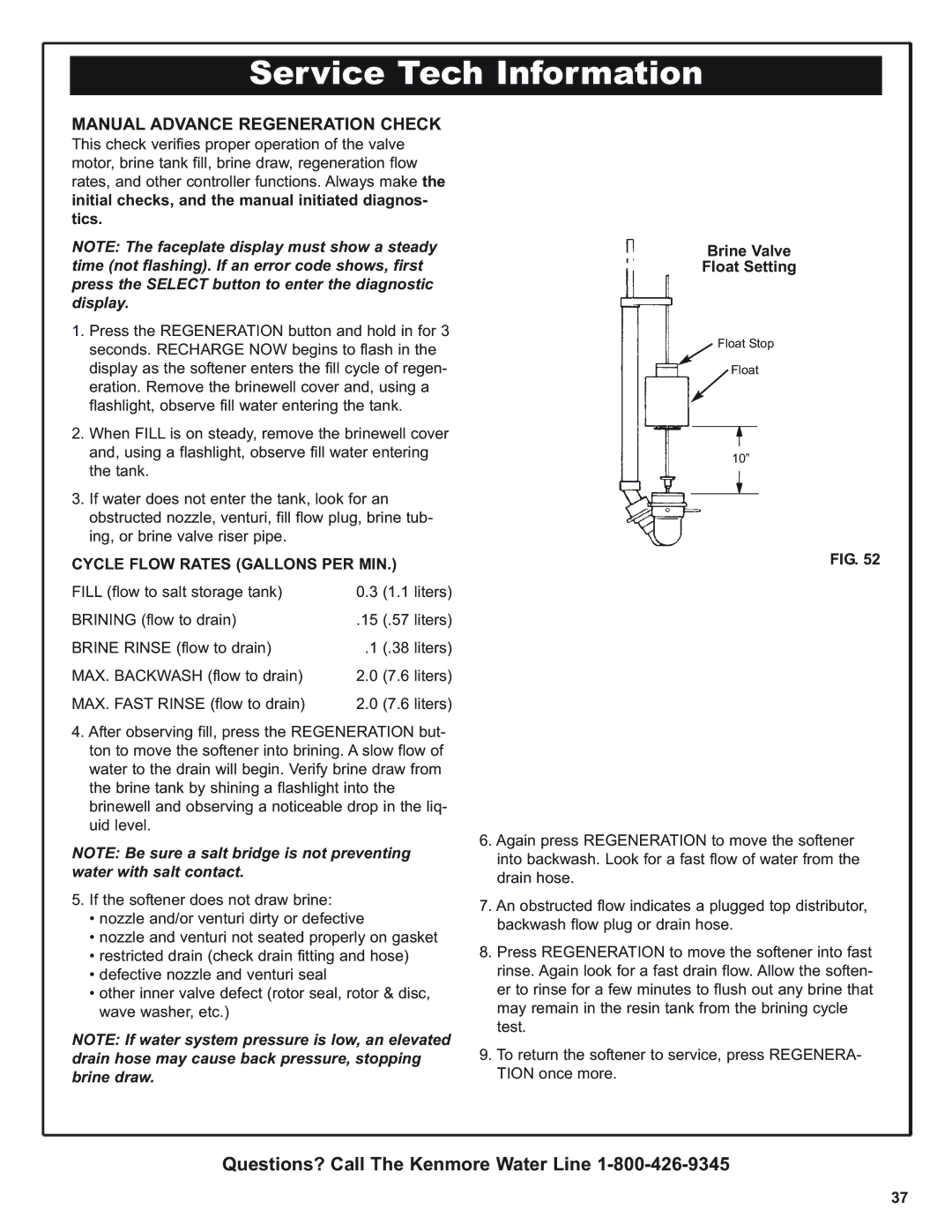

TURBINE OPERATION: If no water is flowing through the softener, the turbine indicator displays three zeros. When water is flowing, the flow bar scrolls across the display, and a 000 to 199 count repeats for each gallon of water passing through the turbine. To check for posi- tive operation of the turbine if zeros are shown, open a nearby soft water faucet and observe the turbine count and flow bar. If you don’t get a reading in the display, with faucet open, pull the sensor from the valve outlet port. Pass a small magnet back and forth in front of the sensor. You should get a reading in the display. If you get a reading, unhook the in and out plumbing and check the turbine for binding.

POSITION SWITCH STATUS: With the valve in service, or any of the recharge cycles, the switch indicator will show open, while the valve is rotating from one position to another, the indicator will show the switch closed. A defect is probable if indications vary from this pattern.

FIG. 48

![]() Motor

Motor

Position Switch ![]()

Sensor

Housing

Turbine

Turbine

Support

and Shaft

Valve Outlet

FIG. 49

Questions? Call The Kenmore Water Line

35