AOSRE50100 specifications

A.O. Smith AOSRE50100 is a high-performance electric water heater designed to provide reliable hot water solutions for residential and commercial applications. This model stands out in the market due to its energy efficiency, innovative technologies, and user-friendly features, ensuring a consistent supply of hot water while optimizing energy consumption.One of the key features of the AOSRE50100 is its impressive recovery rate. The water heater has a powerful heating element that allows it to quickly replenish hot water, making it suitable for households with high hot water demand. Whether for showers, dishwashing, or laundry, this unit can effectively meet the needs of users without prolonged waiting times.

The AOSRE50100 incorporates advanced insulation that minimizes heat loss, contributing to its overall energy efficiency. The higher the insulation level, the less energy spent maintaining the desired water temperature, making the A.O. Smith AOSRE50100 an eco-friendly choice. Its Energy Factor (EF) ratings are noteworthy, showcasing its ability to deliver significant cost savings on utility bills over time.

A.O. Smith has equipped the AOSRE50100 with smart technologies that enhance user convenience. The integrated digital display allows users to easily monitor and adjust the water temperature to their preferred settings. This feature not only provides flexibility but also enhances safety, preventing scalding risks, especially in homes with children.

Durability is another significant characteristic of the A.O. Smith AOSRE50100. Constructed with high-quality materials, this water heater is designed to withstand harsh conditions. The tank is coated with corrosion-resistant materials, extending its lifespan and ensuring longevity. A.O. Smith's commitment to quality craftsmanship also means that customers can rely on warranties that provide peace of mind.

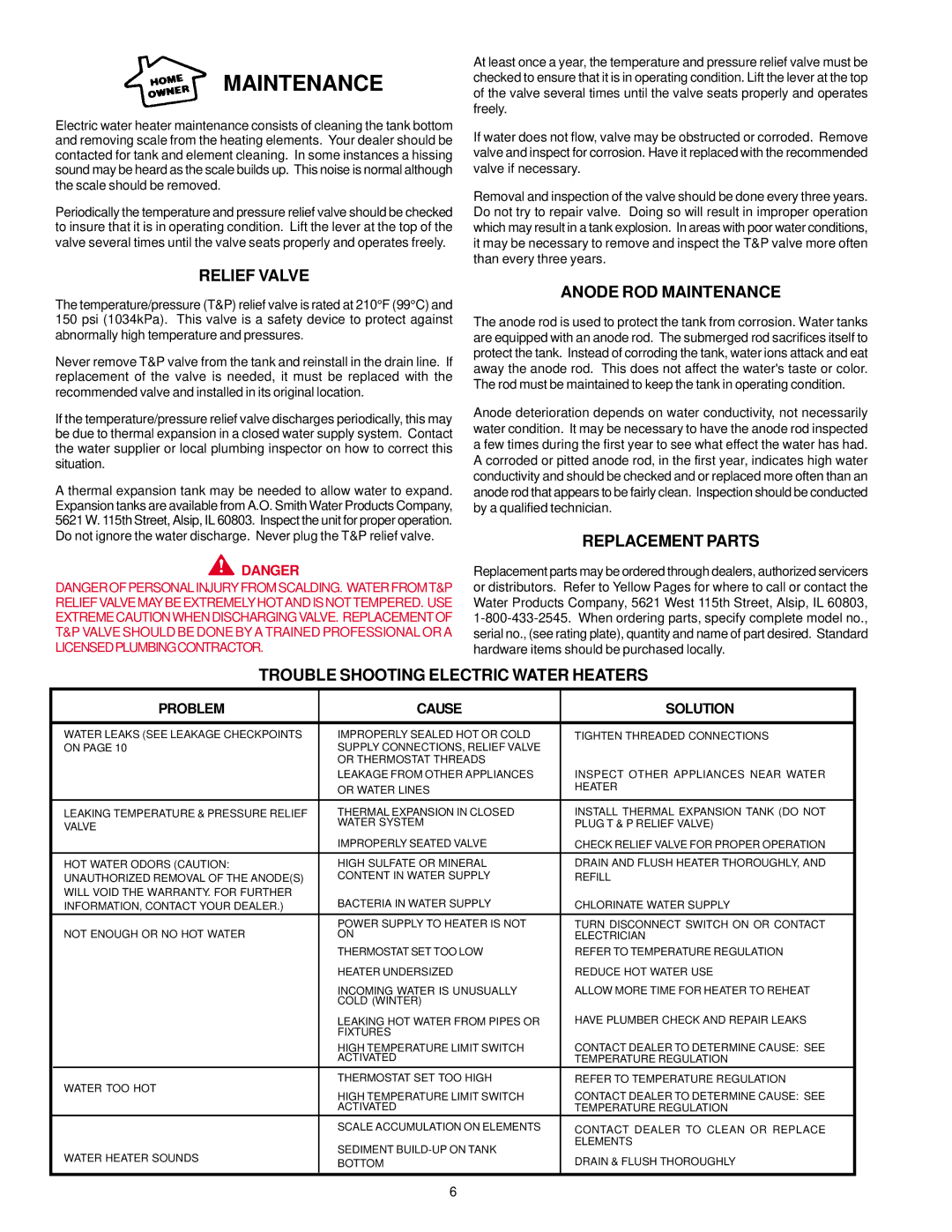

Installation and maintenance of the AOSRE50100 are straightforward. Its compact design allows for versatile placement, making it suitable for installations in tight spaces. Furthermore, regular maintenance is simplified, with easy access to essential components, enabling homeowners to keep the unit in optimal condition effortlessly.

In summary, the A.O. Smith AOSRE50100 is a standout electric water heater that combines performance, efficiency, and convenience. With its high recovery rate, advanced insulation, smart technologies, and durable construction, it provides users with a dependable hot water solution for a modern lifestyle. Whether for residential or commercial use, the AOSRE50100 is an excellent investment for anyone seeking reliable and efficient hot water delivery.