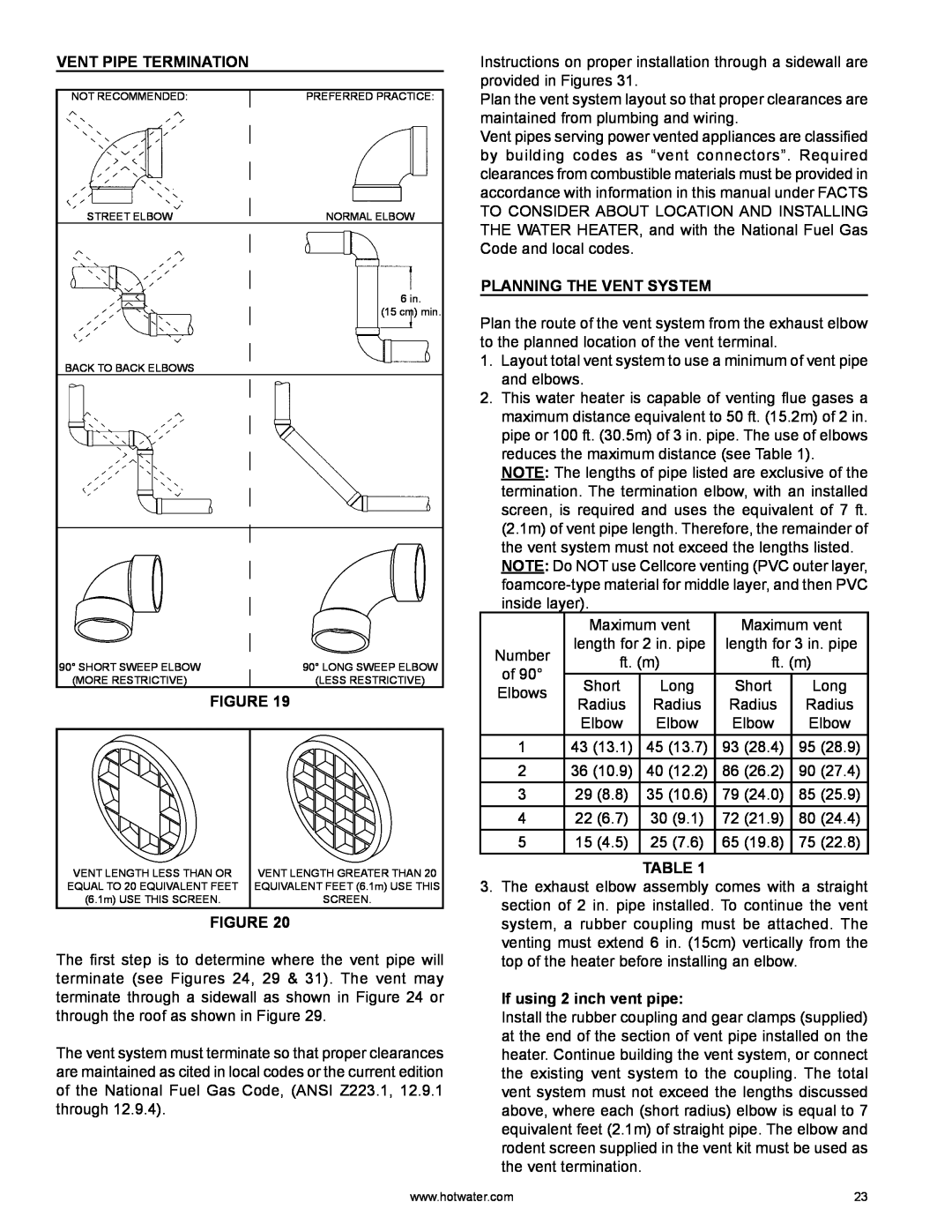

VENT PIPE TERMINATION

NOT RECOMMENDED: | PREFERRED PRACTICE: |

STREET ELBOW | NORMAL ELBOW |

6 in.

(15 cm) min.

BACK TO BACK ELBOWS

90° SHORT SWEEP ELBOW | 90° LONG SWEEP ELBOW |

(MORE RESTRICTIVE) | (LESS RESTRICTIVE) |

FIGURE 19

VENT LENGTH LESS THAN OR | VENT LENGTH GREATER THAN 20 |

EQUAL TO 20 EQUIVALENT FEET | EQUIVALENT FEET (6.1m) USE THIS |

(6.1m) USE THIS SCREEN. | SCREEN. |

FIGURE 20

The first step is to determine where the vent pipe will terminate (see Figures 24, 29 & 31). The vent may terminate through a sidewall as shown in Figure 24 or through the roof as shown in Figure 29.

The vent system must terminate so that proper clearances are maintained as cited in local codes or the current edition of the National Fuel Gas Code, (ANSI Z223.1, 12.9.1 through 12.9.4).

Instructions on proper installation through a sidewall are provided in Figures 31.

Plan the vent system layout so that proper clearances are maintained from plumbing and wiring.

Vent pipes serving power vented appliances are classified by building codes as “vent connectors”. Required clearances from combustible materials must be provided in accordance with information in this manual under FACTS TO CONSIDER ABOUT LOCATION AND INSTALLING THE WATER HEATER, and with the National Fuel Gas Code and local codes.

PLANNING THE VENT SYSTEM

Plan the route of the vent system from the exhaust elbow to the planned location of the vent terminal.

1.Layout total vent system to use a minimum of vent pipe and elbows.

2.This water heater is capable of venting flue gases a maximum distance equivalent to 50 ft. (15.2m) of 2 in. pipe or 100 ft. (30.5m) of 3 in. pipe. The use of elbows reduces the maximum distance (see Table 1).

NOTE: The lengths of pipe listed are exclusive of the termination. The termination elbow, with an installed screen, is required and uses the equivalent of 7 ft. (2.1m) of vent pipe length. Therefore, the remainder of the vent system must not exceed the lengths listed.

NOTE: Do NOT use Cellcore venting (PVC outer layer,

| Maximum vent | Maximum vent | |||

Number | length for 2 in. pipe | length for 3 in. pipe | |||

ft. (m) | ft. (m) | ||||

of 90° | |||||

Short | Long | Short | Long | ||

Elbows | |||||

Radius | Radius | Radius | Radius | ||

| |||||

| Elbow | Elbow | Elbow | Elbow | |

1 | 43 (13.1) | 45 (13.7) | 93 (28.4) | 95 (28.9) | |

2 | 36 (10.9) | 40 (12.2) | 86 (26.2) | 90 (27.4) | |

3 | 29 (8.8) | 35 (10.6) | 79 (24.0) | 85 (25.9) | |

4 | 22 (6.7) | 30 (9.1) | 72 (21.9) | 80 (24.4) | |

5 | 15 (4.5) | 25 (7.6) | 65 (19.8) | 75 (22.8) | |

TABLE 1

3.The exhaust elbow assembly comes with a straight section of 2 in. pipe installed. To continue the vent system, a rubber coupling must be attached. The venting must extend 6 in. (15cm) vertically from the top of the heater before installing an elbow.

If using 2 inch vent pipe:

Install the rubber coupling and gear clamps (supplied) at the end of the section of vent pipe installed on the heater. Continue building the vent system, or connect the existing vent system to the coupling. The total vent system must not exceed the lengths discussed above, where each (short radius) elbow is equal to 7 equivalent feet (2.1m) of straight pipe. The elbow and rodent screen supplied in the vent kit must be used as the vent termination.

www.hotwater.com | 23 |