Fault |

|

|

| Lockout |

|

|

Code | Description | Cause |

|

| Remedy | |

| type |

| ||||

Displayed |

|

|

|

|

| |

|

|

|

|

|

| |

E30 | Blower Error. | Locked Rotor. |

|

| 1. | Check the blower wire harness. |

|

|

|

| Soft | 2. | Change the blower. |

|

|

|

|

| 3. Change the board. | |

E33 | Water Flow Valve | The water valve did not |

|

| 1. Check the water valve wire harness. | |

| Closed. | open when attempting to |

| Soft | 2. Change the board. | |

|

| establish flow. |

|

| 3. | Change the water valve. |

E34 | Proportional Valve | The closed loop control |

|

| Check the proportional gas valve wire | |

| (PV) Response | of the proportional valve |

|

| harness, change the board, change | |

| Too Slow. | is not functioning properly |

| Soft | the gas valve assembly | |

|

| (control error) or the valve |

|

|

| |

|

|

|

|

|

| |

|

| is responding slowly (valve |

|

|

|

|

|

| failure). |

|

|

|

|

E35 | Repeated Flame | Low Gas Inlet Pressure. |

|

| Check the flame rod wire harness, | |

| Loss Fault. |

|

|

| check line gas pressure. If it is above | |

|

|

|

| Soft | 5” WC check the flame rod and if it | |

|

|

|

| looks dirty, clean it up using isopropyl | ||

|

|

|

|

| ||

|

|

|

|

| alcohol and a clean cloth, change the | |

|

|

|

|

| flame rod, change the board | |

E36 | Calibration error. | Calibration sequence |

|

| 1. | Unplug the power cord, check the |

|

| incomplete because end |

|

|

| DIP switch 4 position and put it in |

|

| of |

|

|

| ON position. |

|

| the calibration time, or |

|

| 2. | Increase the set point so that a |

|

| calibration sequence not |

|

|

| |

|

| initiated because of lack of |

| Soft | 3. | Drain the tank in order to lower the |

|

|

|

|

| water temperature so that a “call- | |

|

| has been never calibrated |

|

|

| |

|

| or Calibration is successful |

|

| 4. | Set DIP switch 4 to OFF position. |

|

| but DIP switch 4 not set to |

|

| 5. | Recalibrate the unit. |

|

| “normal”. |

|

| 6. | Change the board. |

E37 | No Water Flow. | The heater could not start |

|

| 1. | Check the water inlet on the heat |

|

| because the water flow was |

|

|

| engine. |

|

| not established. This can be |

|

| 2. | Make a water draw during first 60 |

|

| caused by an air bubble or a |

|

|

| seconds after putting the unit in ON |

|

| blockage in the heat engine |

|

|

| mode (to evacuate possible air from |

|

| water passage, a failed flow |

|

|

| the heat engine water passage). |

|

| sensor or a failed circulation |

|

| 3. | Check wire harness for pump, water |

|

| pump. |

| Soft |

| valve and water flow sensor. |

|

|

|

|

| 4. Check the pump 120Vac voltage | |

|

|

|

|

|

| supply (the pump shall be energized |

|

|

|

|

|

| during the heating mode). |

|

|

|

|

| 5. | Clean or change the water filter. |

|

|

|

|

| 6. Change board. | |

|

|

|

|

| 7. Change pump. | |

|

|

|

|

| 8. Change water valve. | |

E99 | Board Failure. | An internal diagnostic check |

| Soft | Change the board. | |

|

| on the board has failed. |

| |||

|

|

|

|

|

| |

|

| TABLE 5 |

|

|

| |

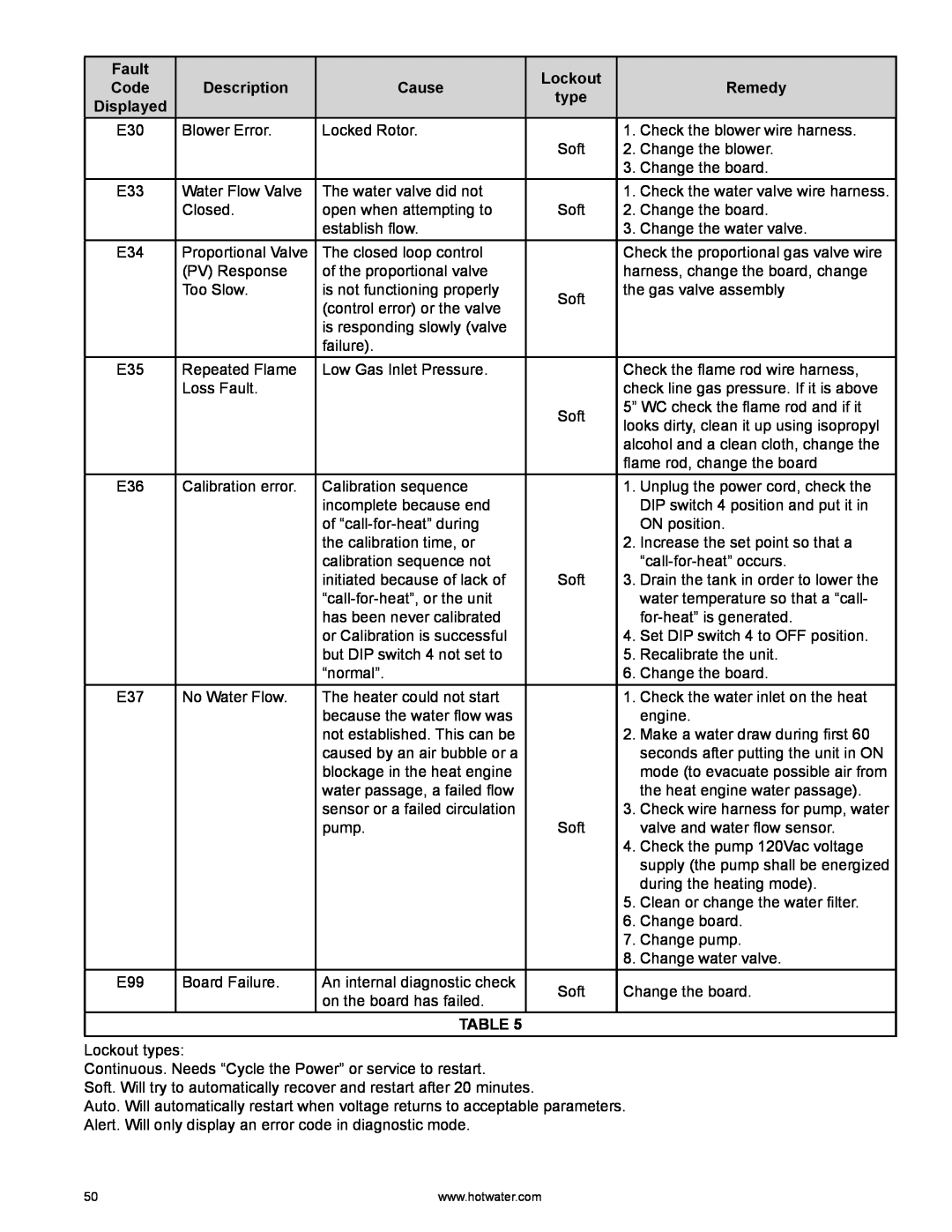

Lockout types: |

|

|

|

|

| |

Continuous. Needs “Cycle the Power” or service to restart. |

|

|

| |||

Soft. Will try to automatically recover and restart after 20 minutes. |

|

|

| |||

Auto. Will automatically restart when voltage returns to acceptable parameters. |

| |||||

Alert. Will only display an error code in diagnostic mode. |

|

|

| |||

50 | www.hotwater.com |