:ANAPURNA XL² | OPERATOR MANUAL |

8. Maintenance.

8.1.Generalinformation

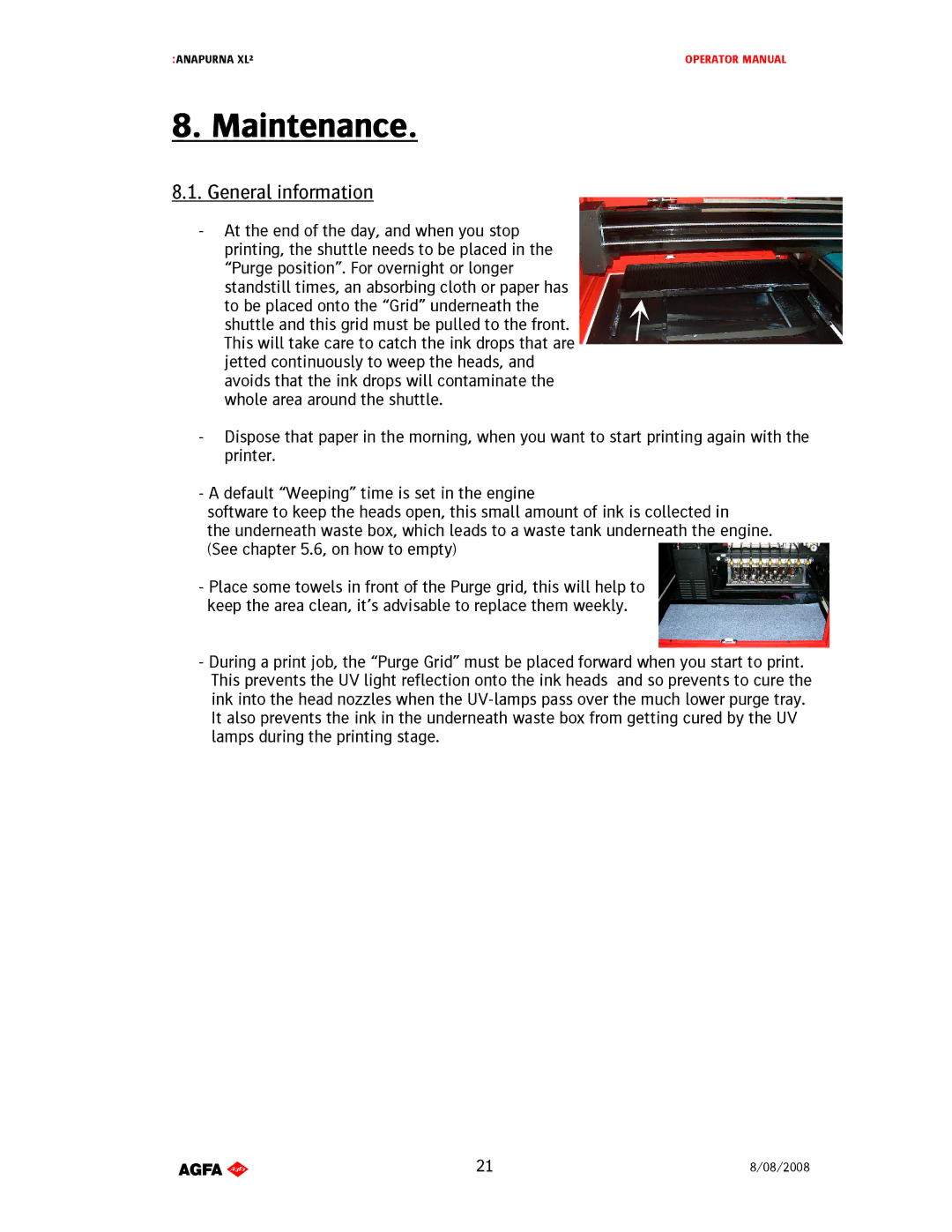

Attheendoftheday,andwhenyoustop

printing,theshuttleneedstobeplacedinthe

“Purgeposition”.Forovernightorlonger

standstilltimes,anabsorbingclothorpaperhas

tobeplacedontothe“Grid”underneaththe

shuttleandthisgridmustbepulledtothefront. Thiswilltakecaretocatchtheinkdropsthatare jettedcontinuouslytoweeptheheads,and avoidsthattheinkdropswillcontaminatethe wholeareaaroundtheshuttle.

Disposethatpaperinthemorning,whenyouwanttosta rtprintingagainwiththe printer.

Adefault“Weeping”timeissetintheengine softwaretokeeptheheadsopen,thissmallamountof inkiscollectedin theunderneathwastebox,whichleadstoawasteta nkunderneaththeengine. (Seechapter5.6,onhowtoempty)

PlacesometowelsinfrontofthePurgegrid,thiswi llhelpto keeptheareaclean,it’sadvisabletoreplacethe mweekly.

Duringaprintjob,the“PurgeGrid”mustbeplace dforwardwhenyoustarttoprint. ThispreventstheUVlightreflectionontotheinkhea dsandsopreventstocurethe inkintotheheadnozzleswhentheUVlampspassover themuchlowerpurgetray. Italsopreventstheinkintheunderneathwastebox fromgettingcuredbytheUV lampsduringtheprintingstage.

AB]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]21] | 8/08/2008] |