:ANAPURNA XL² | OPERATOR MANUAL |

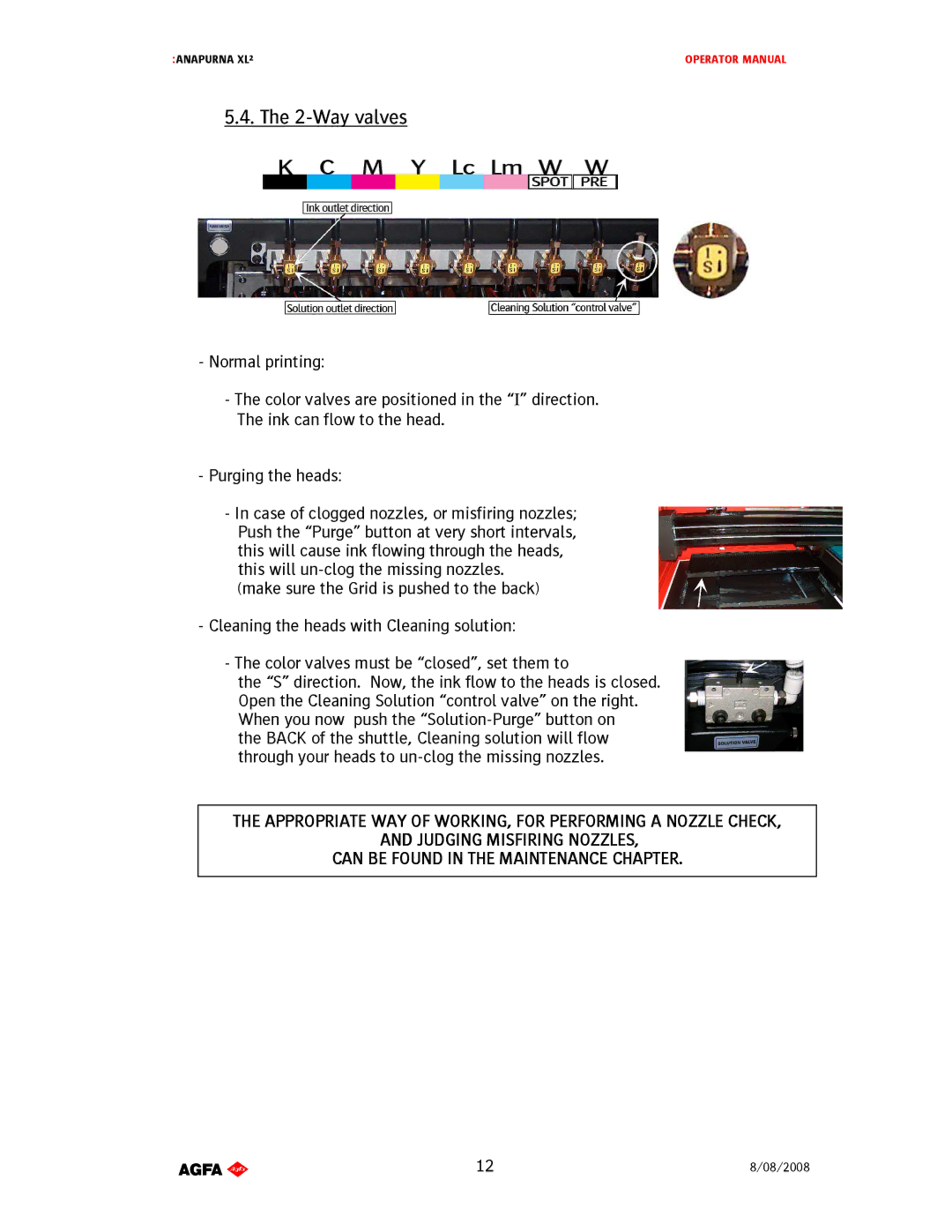

5.4.The2Wayvalves

Normalprinting:

Thecolorvalvesarepositionedinthe“ I”direction.

Theinkcanflowtothehead.

Purgingtheheads:

Incaseofcloggednozzles,ormisfiringnozzles;

Pushthe“Purge”buttonatveryshortintervals,

thiswillcauseinkflowingthroughtheheads,

thiswillunclogthemissingnozzles.

(makesuretheGridispushedtotheback)

CleaningtheheadswithCleaningsolution:

Thecolorvalvesmustbe“closed”,setthemto

the“S”direction.Now,theinkflowtotheheads isclosed. OpentheCleaningSolution“controlvalve”ontherig ht. Whenyounowpushthe“SolutionPurge”buttonon theBACKoftheshuttle,Cleaningsolutionwillflow throughyourheadstounclogthemissingnozzles.

THE APPROPRIATEWAYOFWORKING,FORPERFORMINGANOZZLECHECK,

ANDJUDGINGMISFIRINGNOZZLES,

CANBEFOUNDINTHEMAINTENANCECHAPTER.

AB]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]]12] | 8/08/2008] |