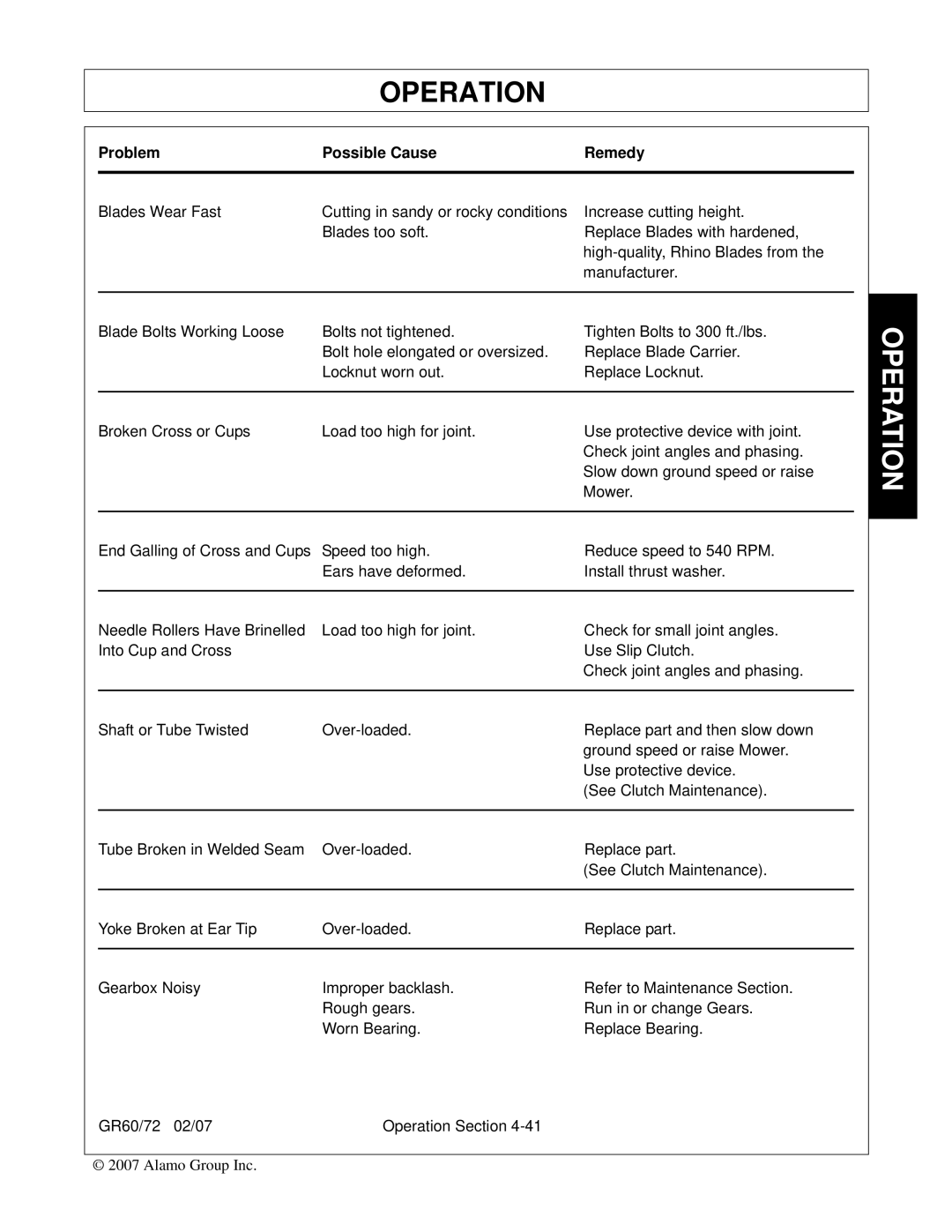

OPERATION

Problem | Possible Cause | Remedy |

|

|

|

Blades Wear Fast | Cutting in sandy or rocky conditions | Increase cutting height. |

| Blades too soft. | Replace Blades with hardened, |

|

| |

|

| manufacturer. |

|

|

|

Blade Bolts Working Loose | Bolts not tightened. | Tighten Bolts to 300 ft./lbs. |

| Bolt hole elongated or oversized. | Replace Blade Carrier. |

| Locknut worn out. | Replace Locknut. |

|

|

|

Broken Cross or Cups | Load too high for joint. | Use protective device with joint. |

|

| Check joint angles and phasing. |

|

| Slow down ground speed or raise |

|

| Mower. |

|

|

|

End Galling of Cross and Cups | Speed too high. | Reduce speed to 540 RPM. |

| Ears have deformed. | Install thrust washer. |

|

|

|

Needle Rollers Have Brinelled | Load too high for joint. | Check for small joint angles. |

Into Cup and Cross |

| Use Slip Clutch. |

|

| Check joint angles and phasing. |

|

|

|

Shaft or Tube Twisted | Replace part and then slow down | |

|

| ground speed or raise Mower. |

|

| Use protective device. |

|

| (See Clutch Maintenance). |

|

|

|

Tube Broken in Welded Seam | Replace part. | |

|

| (See Clutch Maintenance). |

|

|

|

Yoke Broken at Ear Tip | Replace part. | |

|

|

|

Gearbox Noisy | Improper backlash. | Refer to Maintenance Section. |

| Rough gears. | Run in or change Gears. |

| Worn Bearing. | Replace Bearing. |

GR60/72 02/07 | Operation Section |

© 2007 Alamo Group Inc.