B: PREPARING THE SITE

B: PREPARING THE SITE

The standard HDSWG 1000 is designed to operate a single leaf gate. The control box and mechanical units are separate devices. It is necessary to find a suitable location to mount the control box, i.e., post or wall. Separate low voltage and high voltage conduits will be run between the control box and mechanical unit. (See Figure 8.)

To properly install a

The Installation of the HDSWG 1000 MECHANICAL UNIT will require a suitable concrete pad as a mounting base. The dimensions of

104951

Figure 5: Pad Configuration

the concrete pad should be sufficient to allow at least 3" of clearance from each edge of the pad to the nearest operator mounting hole. The top of the pad should be at least 3" above grade to raise the operator above any standing water. The depth of the pad below grade is dependent on the weight and size of the gate and the soil conditions at the site of the installation. ALWAYS FOLLOW LOCAL BUILDING CODES.

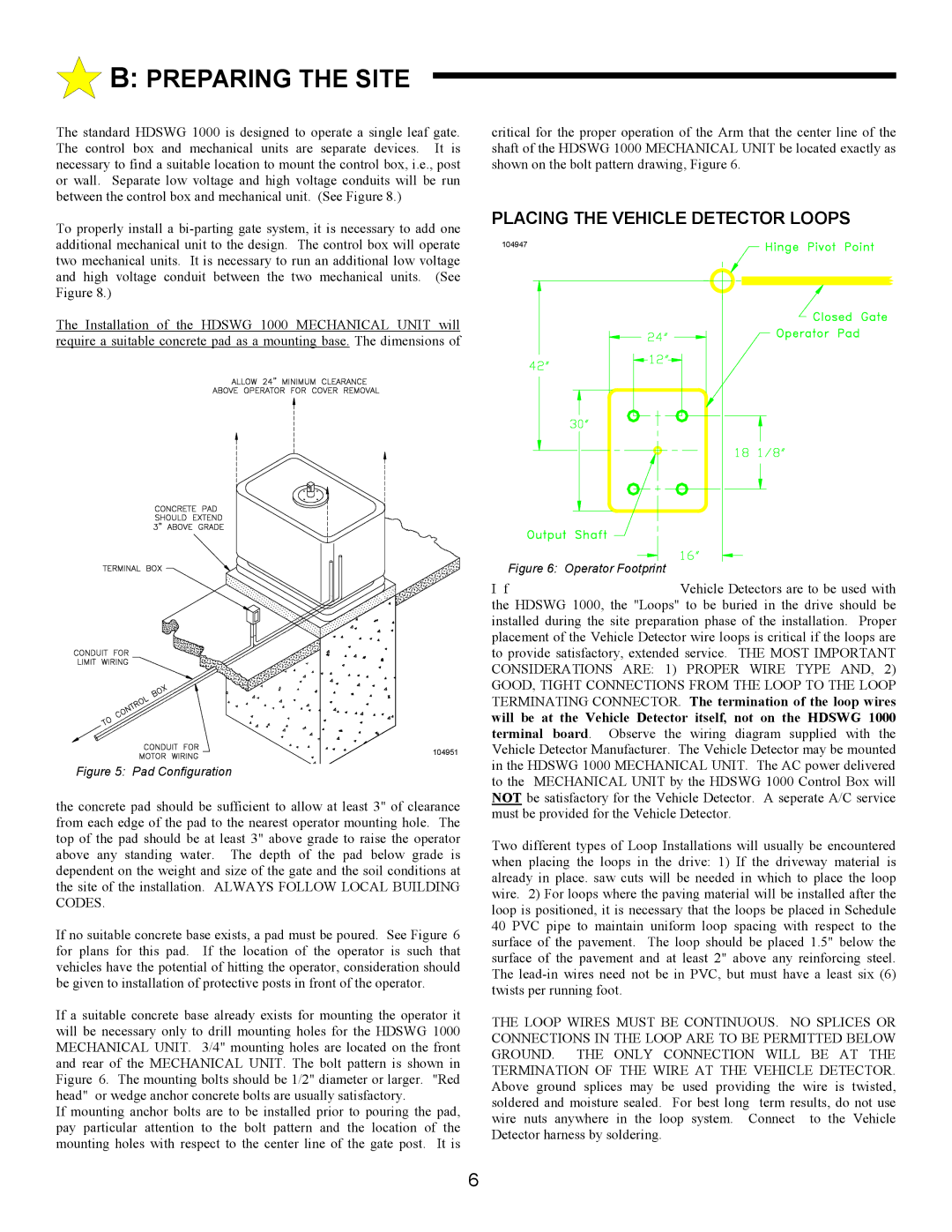

If no suitable concrete base exists, a pad must be poured. See Figure 6 for plans for this pad. If the location of the operator is such that vehicles have the potential of hitting the operator, consideration should be given to installation of protective posts in front of the operator.

If a suitable concrete base already exists for mounting the operator it will be necessary only to drill mounting holes for the HDSWG 1000 MECHANICAL UNIT. 3/4" mounting holes are located on the front and rear of the MECHANICAL UNIT. The bolt pattern is shown in Figure 6. The mounting bolts should be 1/2" diameter or larger. "Red head" or wedge anchor concrete bolts are usually satisfactory.

If mounting anchor bolts are to be installed prior to pouring the pad, pay particular attention to the bolt pattern and the location of the mounting holes with respect to the center line of the gate post. It is

critical for the proper operation of the Arm that the center line of the shaft of the HDSWG 1000 MECHANICAL UNIT be located exactly as shown on the bolt pattern drawing, Figure 6.

PLACING THE VEHICLE DETECTOR LOOPS

104947

Figure 6: Operator Footprint

I fVehicle Detectors are to be used with the HDSWG 1000, the "Loops" to be buried in the drive should be installed during the site preparation phase of the installation. Proper placement of the Vehicle Detector wire loops is critical if the loops are to provide satisfactory, extended service. THE MOST IMPORTANT CONSIDERATIONS ARE: 1) PROPER WIRE TYPE AND, 2) GOOD, TIGHT CONNECTIONS FROM THE LOOP TO THE LOOP TERMINATING CONNECTOR. The termination of the loop wires will be at the Vehicle Detector itself, not on the HDSWG 1000 terminal board. Observe the wiring diagram supplied with the Vehicle Detector Manufacturer. The Vehicle Detector may be mounted in the HDSWG 1000 MECHANICAL UNIT. The AC power delivered to the MECHANICAL UNIT by the HDSWG 1000 Control Box will NOT be satisfactory for the Vehicle Detector. A seperate A/C service must be provided for the Vehicle Detector.

Two different types of Loop Installations will usually be encountered when placing the loops in the drive: 1) If the driveway material is already in place. saw cuts will be needed in which to place the loop wire. 2) For loops where the paving material will be installed after the loop is positioned, it is necessary that the loops be placed in Schedule 40 PVC pipe to maintain uniform loop spacing with respect to the surface of the pavement. The loop should be placed 1.5" below the surface of the pavement and at least 2" above any reinforcing steel. The

THE LOOP WIRES MUST BE CONTINUOUS. NO SPLICES OR CONNECTIONS IN THE LOOP ARE TO BE PERMITTED BELOW GROUND. THE ONLY CONNECTION WILL BE AT THE TERMINATION OF THE WIRE AT THE VEHICLE DETECTOR. Above ground splices may be used providing the wire is twisted, soldered and moisture sealed. For best long term results, do not use wire nuts anywhere in the loop system. Connect to the Vehicle Detector harness by soldering.

6