PRE-INSTALLATION

The Allstar HDSWG 1000 Vehicular Gate Operator will provide convenience and assurance to the ultimate users for many years. It is ruggedly built of the finest materials and has been thoroughly inspected and tested at the Allstar factory. It has many features that will aid in the installation and testing of the complete gate system. The HDSWG 1000 has been evaluated by Underwriters Laboratory, Inc. (UL) and is certified to comply with UL Standard for Safety 325, as evidenced by the UL symbol on the name plate. (115 Volt version only.)

NOTICE

BEFORE ATTEMPTING INSTALLATION, READ THIS MANUAL CAREFULLY SO YOU WILL BE THOROUGHLY FAMILIAR WITH THE

FEATURES OF THE HDSWG 1000 AND ITS PROPER INSTALLATION PROCEDURES.

Because the Allstar HDSWG 1000 (as well as gate operators sold by other manufactures) is designed to start and move gates weighing as much as 1200 pounds, or

The gate operator is only one part of a complete automatic gate operating system. As each location and usage is different, a properly designed system will include all applicable safety devices.

As the designer and installer of the GATE SYSTEM, you must advise the purchaser on the proper use of the gate system. You also have the primary responsibility of insuring that ALL possible operational hazards have been considered and eliminated. YOU MUST ADVISE AND WARN the purchaser and the ultimate user of ANY HAZARDS that you have not been able to eliminate.

The Allstar HDSWG 1000 has a

sensors, protective screen mesh, etc) to eliminate hazards in your gate system design.

*The Allstar HDSWG 1000

| NOTICE |

|

| |

THE | IMPORTANT | SAFEGUARDS | AND | |

INSTRUCTIONS IN THIS MANUAL | CANNOT | |||

COVER ALL POSSIBLE CONDITIONS AND SITUATIONS | ||||

WHICH MAY OCCUR DURING ITS USE. IT MUST BE | ||||

UNDERSTOOD THAT COMMON SENSE AND CAUTION | ||||

MUST BE EXERCISED BY THE PERSON(S) INSTALLING, | ||||

MAINTAINING AND OPERATING THE EQUIPMENT | ||||

DESCRIBED HEREIN. DO NOT USE THIS EQUIPMENT FOR | ||||

ANY OTHER THAN ITS INTENDED PURPOSE — | ||||

OPERATING A SWING GATE. |

|

|

| |

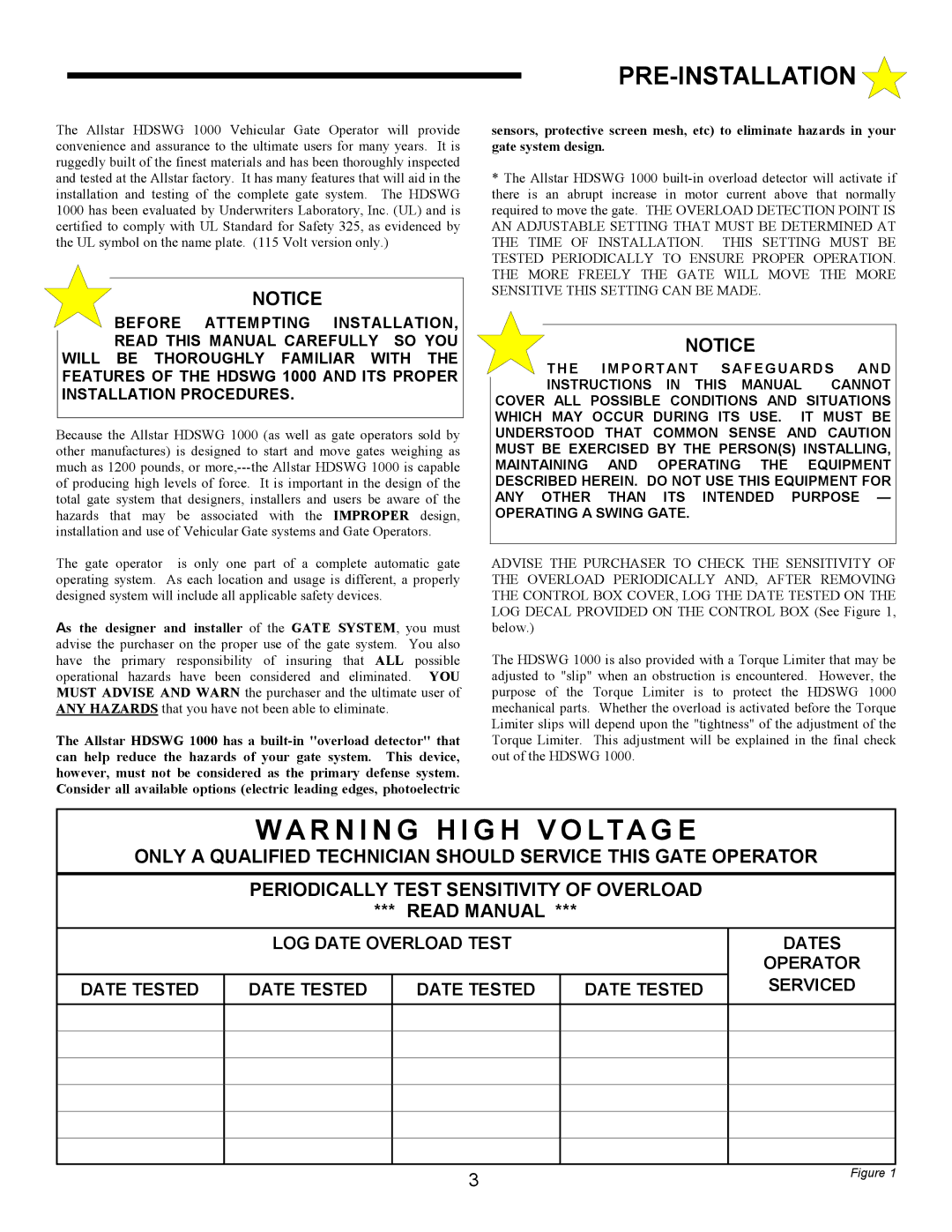

ADVISE THE PURCHASER TO CHECK THE SENSITIVITY OF THE OVERLOAD PERIODICALLY AND, AFTER REMOVING THE CONTROL BOX COVER, LOG THE DATE TESTED ON THE LOG DECAL PROVIDED ON THE CONTROL BOX (See Figure 1, below.)

The HDSWG 1000 is also provided with a Torque Limiter that may be adjusted to "slip" when an obstruction is encountered. However, the purpose of the Torque Limiter is to protect the HDSWG 1000 mechanical parts. Whether the overload is activated before the Torque Limiter slips will depend upon the "tightness" of the adjustment of the Torque Limiter. This adjustment will be explained in the final check out of the HDSWG 1000.

WA R N I N G H I G H V O LTA G E

ONLY A QUALIFIED TECHNICIAN SHOULD SERVICE THIS GATE OPERATOR

PERIODICALLY TEST SENSITIVITY OF OVERLOAD

*** READ MANUAL ***

LOG DATE OVERLOAD TEST

DATE TESTED | DATE TESTED | DATE TESTED | DATE TESTED |

|

|

|

|

DATES

OPERATOR SERVICED

3 | Figure 1 |

|