1767-SK/III, 2800-SK/III, 767-SK/III specifications

The Alto-Shaam 767-SK/III is a sophisticated and versatile cooking solution designed to meet the demanding needs of commercial kitchens, particularly in restaurants, catering, and institutional food service operations. This innovative unit combines advanced technology with user-friendly features, making it an exceptional choice for culinary professionals.One of the standout features of the 767-SK/III is its unique Halo Heat technology. This innovative system provides uniform cooking temperatures by using a low-temperature heat source that envelops food from all sides. Unlike traditional ovens that can create hot spots, Halo Heat ensures consistent cooking results, thereby enhancing food quality and reducing the chance of overcooking.

The Alto-Shaam 767-SK/III is equipped with a state-of-the-art digital control panel, which allows chefs to easily program cooking times and temperatures. The intuitive interface provides precise control over cooking processes and enables operators to select various cooking methods, such as baking, roasting, and holding. This flexibility is crucial in fast-paced kitchen environments where time and efficiency are paramount.

Another notable characteristic is the unit's ability to hold food at ideal serving temperatures without compromising taste or texture. The integrated holding function creates a "hot hold" environment that keeps dishes warm without drying them out. This feature is particularly beneficial for busy establishments that need to serve large volumes of food while maintaining quality standards.

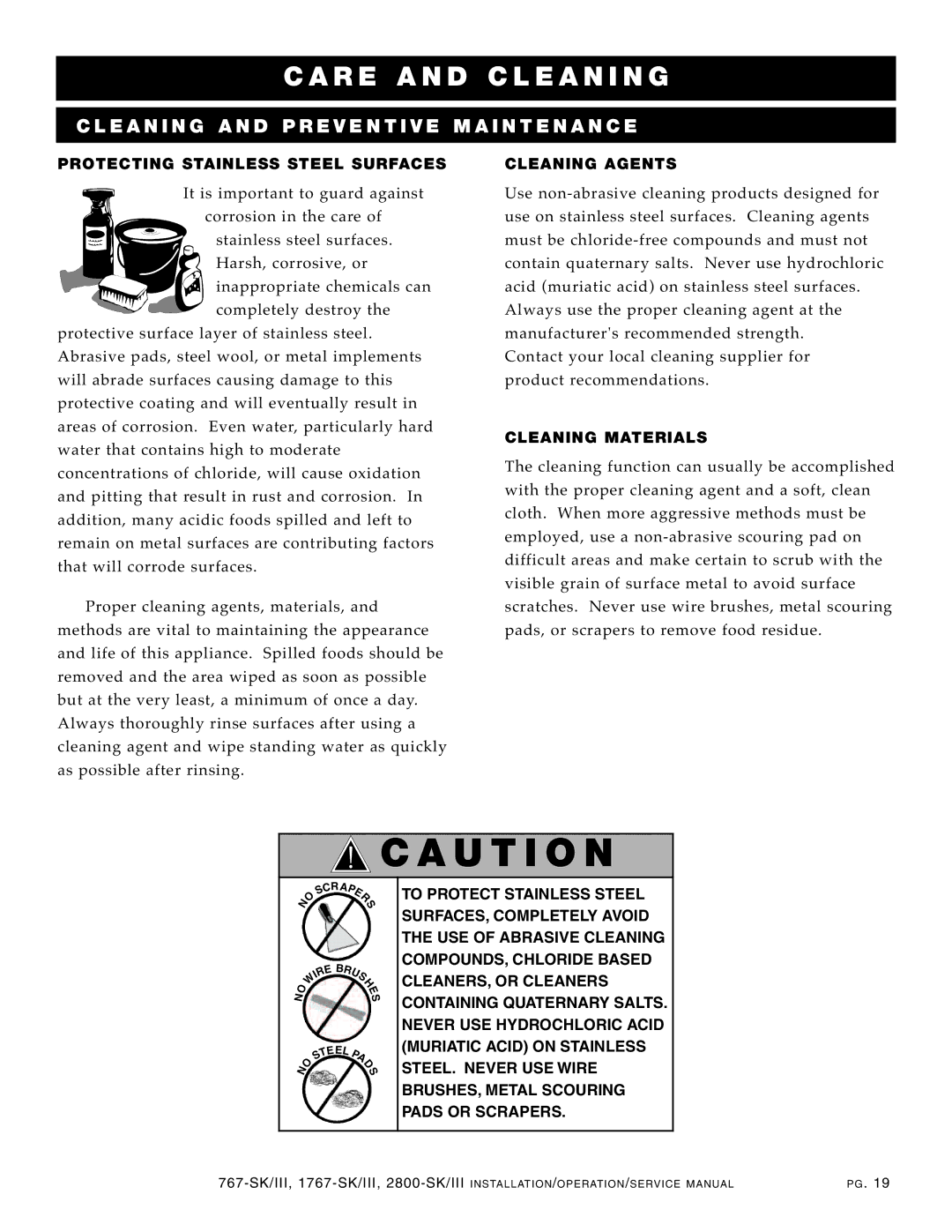

Constructed with durable stainless steel, the Alto-Shaam 767-SK/III is built to withstand the rigors of daily use in a busy kitchen. Its compact design makes it space-efficient, allowing it to fit seamlessly into various kitchen layouts. Furthermore, the unit is easy to clean, with removable racks and a smooth interior surface that promotes optimal sanitation.

The Alto-Shaam 767-SK/III also integrates energy-efficient technologies, minimizing energy consumption without sacrificing performance. This not only reduces operational costs for food service operations but also aligns with sustainability efforts in the industry.

In summary, the Alto-Shaam 767-SK/III stands out as a reliable and innovative cooking solution that combines advanced technology, versatility, and efficiency. With its Halo Heat technology, user-friendly controls, exceptional holding capabilities, and durable construction, this unit is a valuable asset for any commercial kitchen aiming to deliver high-quality meals consistently.