Page 5 has some of the diagnostic parameters. MAF and MAFF show mass air flow sensor output. MISP and MISR are used for misfire diagnosis. MAP shows the manifold air pressure, while IAC shows the idle air controller position in counts, and TPSV shows the throttle position switch output in volts.

The final sample page is an example of how you might diagnose engine knock (pinging). You can log these parameters and determine under what conditions – speed, rpm, throttle position – the knock retard (KR) is occurring.

Remember that these are just starting points. Any parameter on any page can be customized. Just click on the item, then click Config. Your changes will be saved so whichever page you customize will still be customized the next time you use your scanner.

Logging

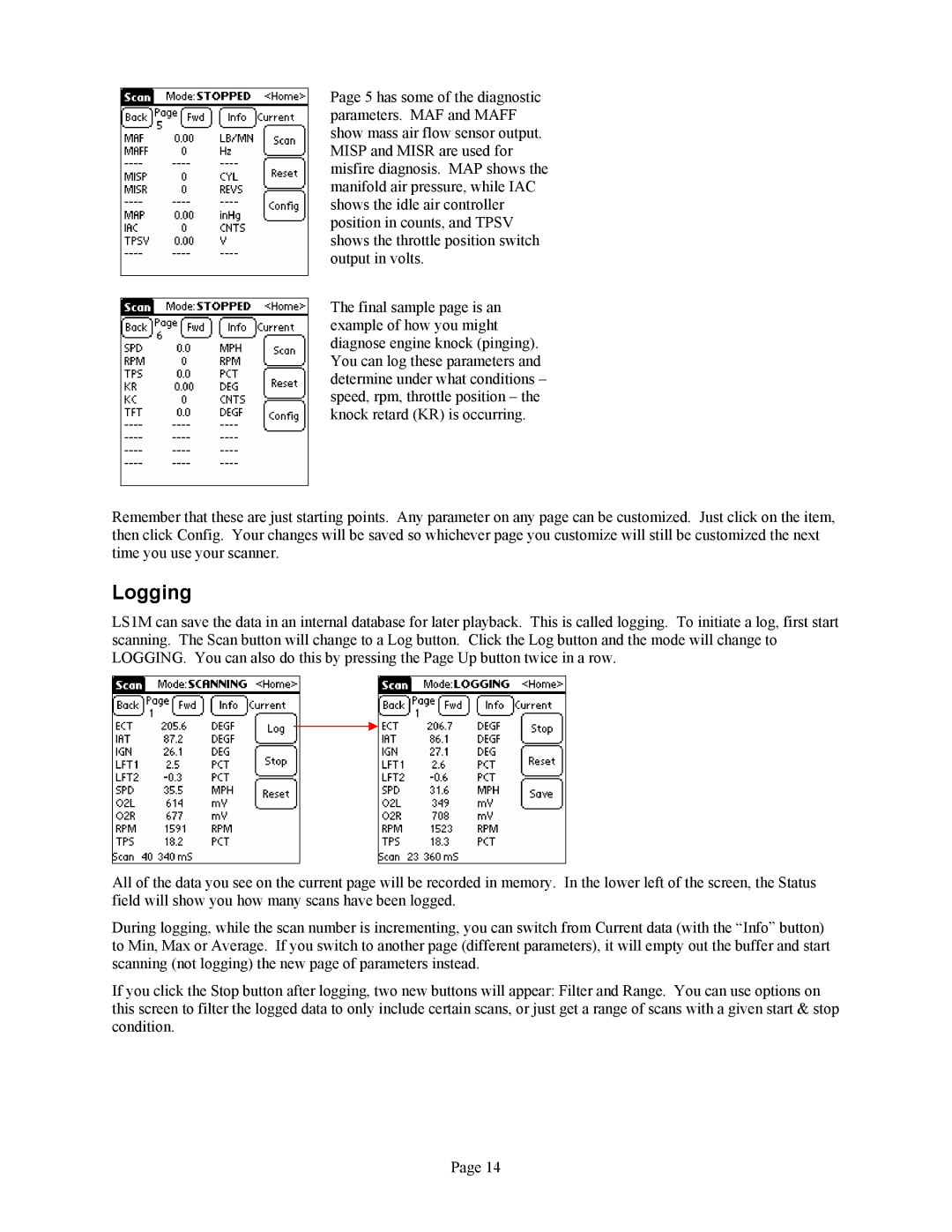

LS1M can save the data in an internal database for later playback. This is called logging. To initiate a log, first start scanning. The Scan button will change to a Log button. Click the Log button and the mode will change to LOGGING. You can also do this by pressing the Page Up button twice in a row.

All of the data you see on the current page will be recorded in memory. In the lower left of the screen, the Status field will show you how many scans have been logged.

During logging, while the scan number is incrementing, you can switch from Current data (with the “Info” button) to Min, Max or Average. If you switch to another page (different parameters), it will empty out the buffer and start scanning (not logging) the new page of parameters instead.

If you click the Stop button after logging, two new buttons will appear: Filter and Range. You can use options on this screen to filter the logged data to only include certain scans, or just get a range of scans with a given start & stop condition.

Page 14