MAINTENANCE INSTRUCTIONS FOR LARGE SUMP

This compressor is an

INSTALLATION

The base mounted compressor should be securely bolted down with 1/2" grade five or better cap screws torqued to 70 ft. pounds, making sure that motor and compressor pulleys are aligned and belt tension is correct. The crankcase should be filled with five quarts (4.7 liter) of SAE 20 W engine oil. The compressor must always be installed to rotate clockwise when viewed from the pulley end. The oil pump will not function if rotation is not correct.

SCHEDULED MAINTENANCE

NOTE: When checking or adding oil or servicing the crankcase breather, care should be taken to prevent dirt or foreign material from entering the breather or oil sump.

Every 7,500 miles or seven weeks, whichever occurs first: Check oil level - replenish to top of filler plug opening. Replace both air cleaner filter elements and clean covers. Check belts and replace if broken, damaged or missing.

Every 15,000 miles or 14 weeks, whichever occurs first: Remove crankcase ventilator, clean ports and replace with freshly oiled curled hair.

Every 22,500 miles or 21 weeks, whichever occurs first: Drain oil and refill with fresh SAE 20 W engine oil. Inspect all bolts, fittings and plugs to ensure that all are tight.

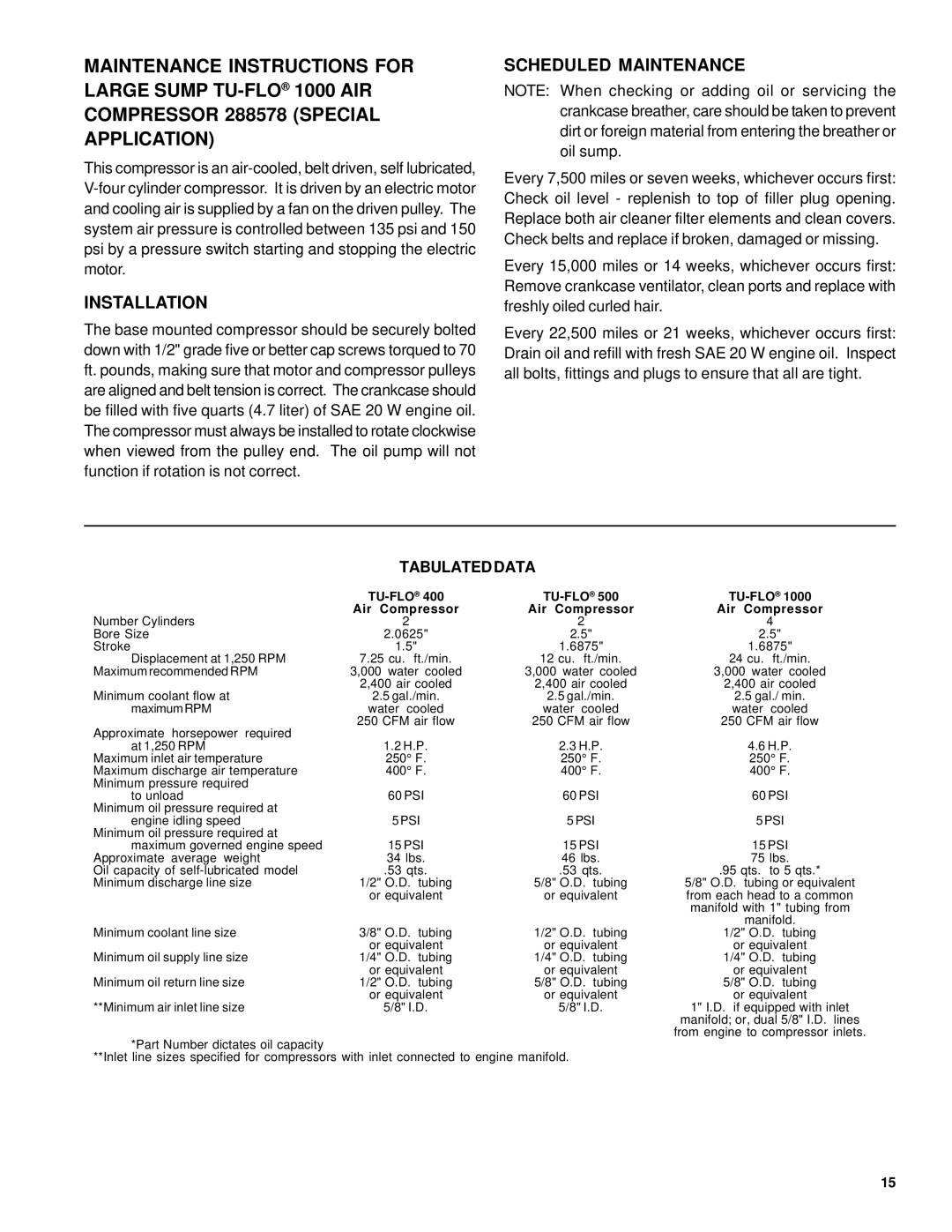

TABULATED DATA

|

| ||

| Air Compressor | Air Compressor | Air Compressor |

Number Cylinders | 2 | 2 | 4 |

Bore Size | 2.0625" | 2.5" | 2.5" |

Stroke | 1.5" | 1.6875" | 1.6875" |

Displacement at 1,250 RPM | 7.25 cu. ft./min. | 12 cu. ft./min. | 24 cu. ft./min. |

Maximum recommended RPM | 3,000 water cooled | 3,000 water cooled | 3,000 water cooled |

| 2,400 air cooled | 2,400 air cooled | 2,400 air cooled |

Minimum coolant flow at | 2.5 gal./min. | 2.5 gal./min. | 2.5 gal./ min. |

maximumRPM | water cooled | water cooled | water cooled |

Approximate horsepower required | 250 CFM air flow | 250 CFM air flow | 250 CFM air flow |

|

|

| |

at 1,250 RPM | 1.2 H.P. | 2.3 H.P. | 4.6 H.P. |

Maximum inlet air temperature | 250° F. | 250° F. | 250° F. |

Maximum discharge air temperature | 400° F. | 400° F. | 400° F. |

Minimum pressure required |

|

|

|

to unload | 60 PSI | 60 PSI | 60 PSI |

Minimum oil pressure required at |

|

|

|

engine idling speed | 5 PSI | 5 PSI | 5 PSI |

Minimum oil pressure required at |

|

|

|

maximum governed engine speed | 15 PSI | 15 PSI | 15 PSI |

Approximate average weight | 34 lbs. | 46 lbs. | 75 lbs. |

Oil capacity of | .53 qts. | .53 qts. | .95 qts. to 5 qts.* |

Minimum discharge line size | 1/2" O.D. tubing | 5/8" O.D. tubing | 5/8" O.D. tubing or equivalent |

| or equivalent | or equivalent | from each head to a common |

|

|

| manifold with 1" tubing from |

|

|

| manifold. |

Minimum coolant line size | 3/8" O.D. tubing | 1/2" O.D. tubing | 1/2" O.D. tubing |

| or equivalent | or equivalent | or equivalent |

Minimum oil supply line size | 1/4" O.D. tubing | 1/4" O.D. tubing | 1/4" O.D. tubing |

| or equivalent | or equivalent | or equivalent |

Minimum oil return line size | 1/2" O.D. tubing | 5/8" O.D. tubing | 5/8" O.D. tubing |

| or equivalent | or equivalent | or equivalent |

**Minimum air inlet line size | 5/8" I.D. | 5/8" I.D. | 1" I.D. if equipped with inlet |

|

|

| manifold; or, dual 5/8" I.D. lines |

from engine to compressor inlets.

*Part Number dictates oil capacity

**Inlet line sizes specified for compressors with inlet connected to engine manifold.

15