DESCRIPTION AND OPERATION

GENERAL

The function of the air compressor is to build up and maintain the air pressure required to operate air powered devices in air brake or air auxiliary systems.

DESCRIPTION

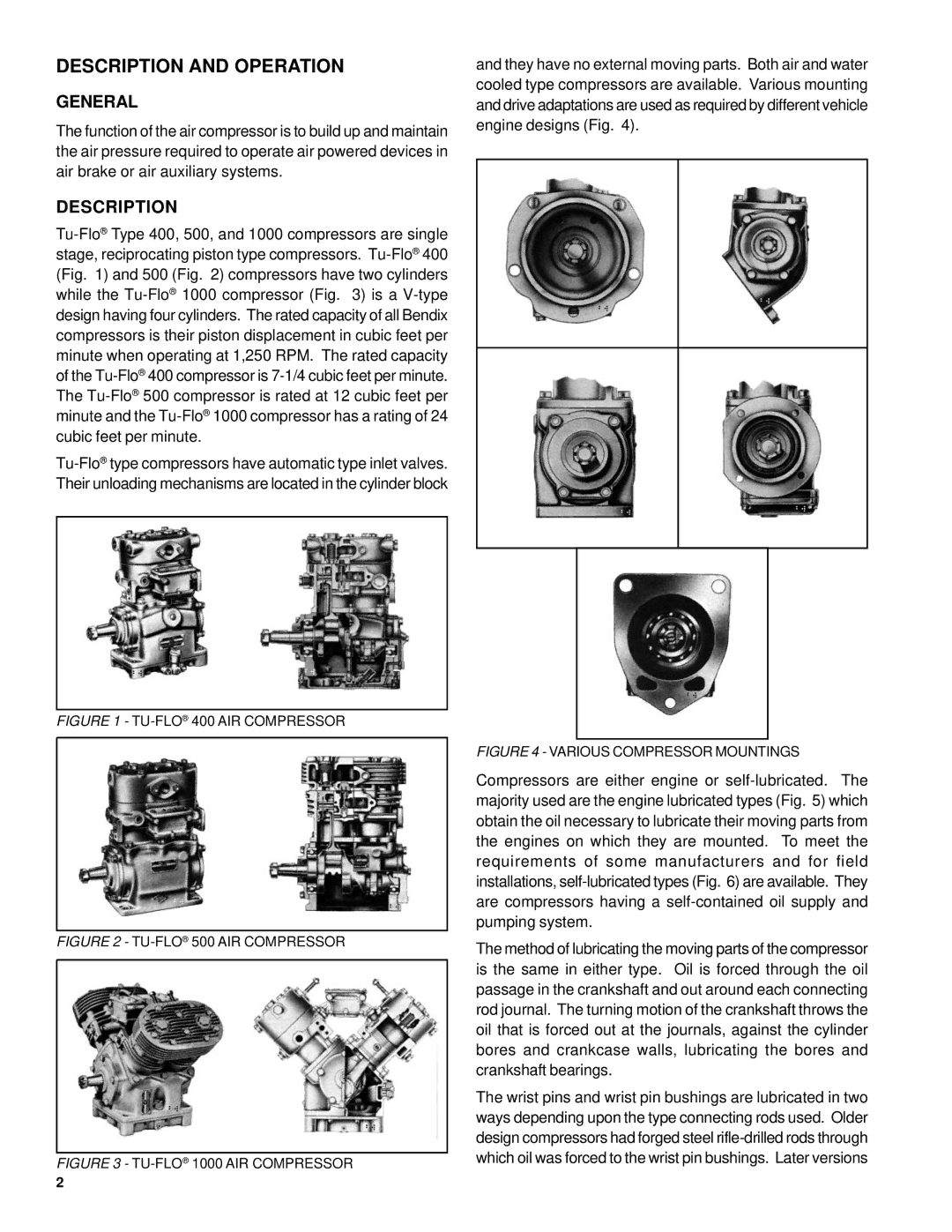

and they have no external moving parts. Both air and water cooled type compressors are available. Various mounting and drive adaptations are used as required by different vehicle engine designs (Fig. 4).

FIGURE 1 - TU-FLO® 400 AIR COMPRESSOR

FIGURE 2 - TU-FLO® 500 AIR COMPRESSOR

FIGURE 3 - TU-FLO® 1000 AIR COMPRESSOR

2

FIGURE 4 - VARIOUS COMPRESSOR MOUNTINGS

Compressors are either engine or

The method of lubricating the moving parts of the compressor is the same in either type. Oil is forced through the oil passage in the crankshaft and out around each connecting rod journal. The turning motion of the crankshaft throws the oil that is forced out at the journals, against the cylinder bores and crankcase walls, lubricating the bores and crankshaft bearings.

The wrist pins and wrist pin bushings are lubricated in two ways depending upon the type connecting rods used. Older design compressors had forged steel