Tests

Test 1: Excessive Oil Leakage at the

Head Gasket

Exterior leaks at the head gasket are not a sign that oil is being passed into the air charging system. Oil weepage at the head gasket does not prevent the compressor from building air.

Observe the amount of weepage from the head gasket.

If the oil is only around the cylinder head area, it is acceptable (return the vehicle to service), but, if the oil weepage extends down to the nameplate area of the compressor, the gasket can be replaced.

LOOK

FOR

WEEPAGE

Test 2: Air Brake System and Accessory Leakage

Inspect for air leaks when working on a vehicle and repair them promptly.

Park the vehicle on level ground and chock wheels. Build system pressure to governor

Step 1: Observe the dash gauges for two additional minutes without the service brakes applied.

Step 2: Apply the service brakes and allow the pressure to stabilize. Continue holding for two minutes (you may use a block of wood to hold the

pedal in position.) Observe the dash gauges.

If you see any noticeable decrease of the dash air gauge readings (i.e. more than 4 psi, plus two psi for each additional trailer) during either two minute test, repair the leaks and repeat this test to confirm that they have been repaired.

Air leaks can also be found in the charging system, parking brakes, and/or other components - inspect and repair as necessary.

Test 3: Air Compressor Discharge

Temperature and Air Dryer Inlet | (* Note that only vehicles that have passed Test 2 | |||||||||||

| Temperature* |

| would be candidates for this test.) | |||||||||

Caution: The temperatures used in this test | 4. | Then, while maintaining max rpm and | ||||||||||

are not normal vehicle conditions. | ||||||||||||

| pressure range, measure and record the | |||||||||||

Above normal temperatures can cause oil (as |

| |||||||||||

| surface temperature of the fittings: | |||||||||||

vapor) to pass through the air dryer into the |

| |||||||||||

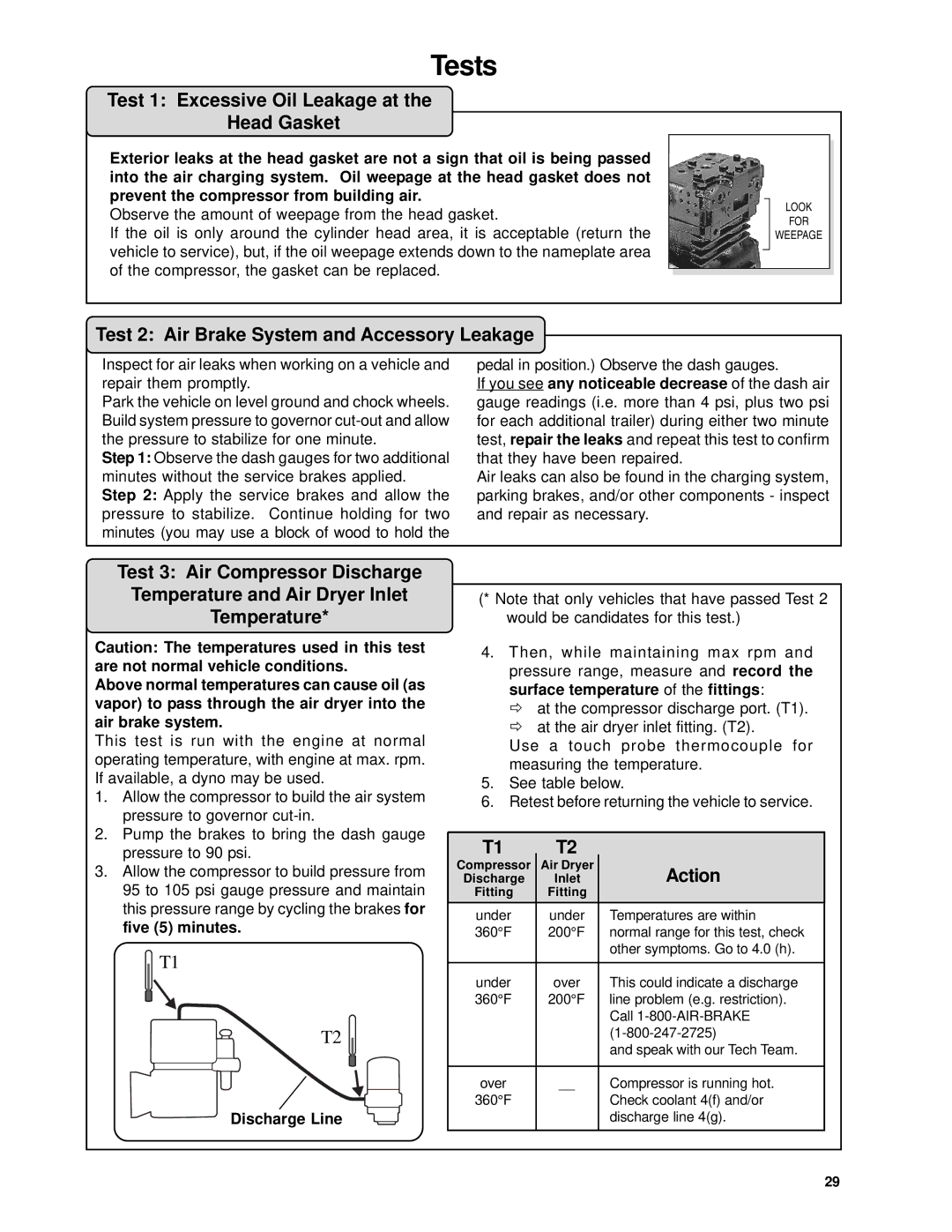

| ð at the compressor discharge port. (T1). | |||||||||||

air brake system. |

| |||||||||||

| ð at the air dryer inlet fitting. (T2). | |||||||||||

This test is run with the engine at normal |

| |||||||||||

| Use a touch probe thermocouple for | |||||||||||

operating temperature, with engine at max. rpm. |

| |||||||||||

| measuring the temperature. | |||||||||||

If available, a dyno may be used. |

| |||||||||||

5. | See table below. | |||||||||||

1. Allow the compressor to build the air system | ||||||||||||

6. | Retest before returning the vehicle to service. | |||||||||||

pressure to governor | ||||||||||||

|

|

|

|

| ||||||||

2. Pump the brakes to bring the dash gauge |

|

|

|

|

| |||||||

T1 |

| T2 |

|

| ||||||||

pressure to 90 psi. |

|

|

| |||||||||

3. Allow the compressor to build pressure from | Compressor | Air Dryer | Action |

| ||||||||

Discharge | Inlet |

| ||||||||||

95 to 105 psi gauge pressure and maintain | Fitting | Fitting |

|

| ||||||||

this pressure range by cycling the brakes for |

|

|

|

|

| |||||||

under | under | Temperatures are within |

| |||||||||

five (5) minutes. |

| |||||||||||

360°F | 200°F | normal range for this test, check |

| |||||||||

| T1 |

|

|

| other symptoms. Go to 4.0 (h). |

| ||||||

|

|

|

|

|

| |||||||

| under | over | This could indicate a discharge |

| ||||||||

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

| 360°F | 200°F | line problem (e.g. restriction). |

| ||

|

|

|

|

|

|

|

|

|

| Call |

| |

| T2 |

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

| and speak with our Tech Team. |

| |

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| over | __ | Compressor is running hot. |

| ||

|

|

|

|

|

|

| 360°F |

| Check coolant 4(f) and/or |

| ||

| Discharge Line |

|

|

|

|

|

| discharge line 4(g). |

| |||

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| |

29