ROBUST TECHNOLOGY FOR LONG-TERM HEAVY-DUTY USE.

A real concept: | The operating |

frequency determines | |

| the performance |

A

Fan

How a good idea was consistently further developed: The designation

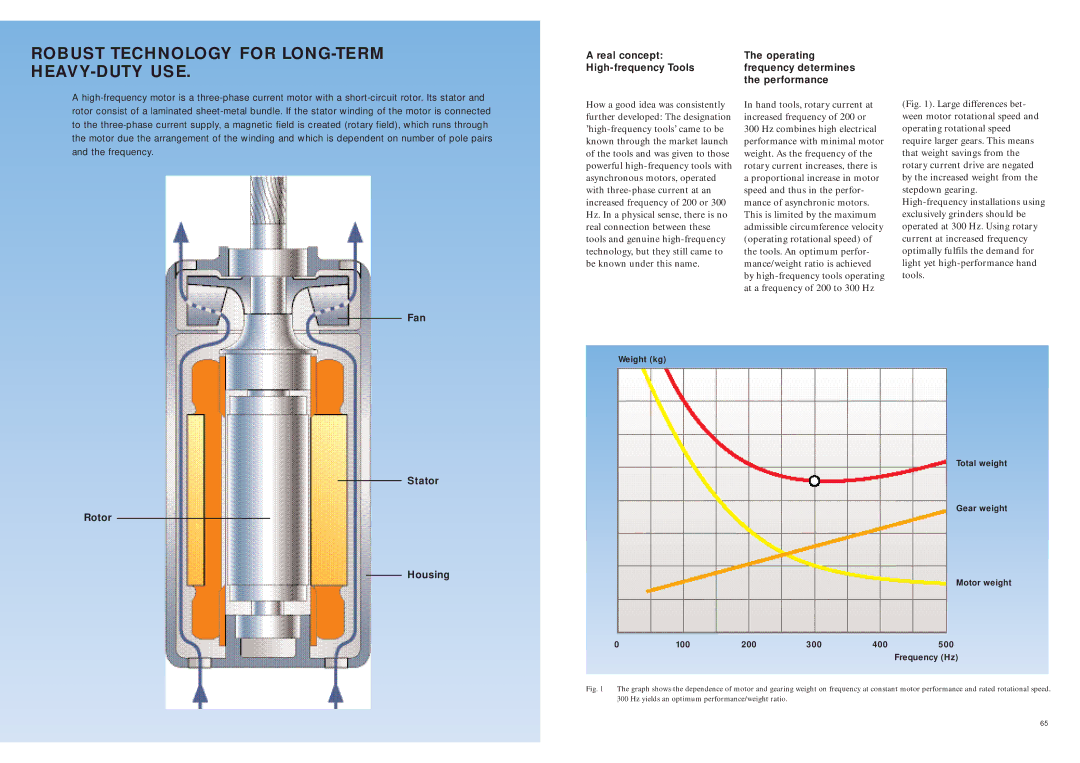

In hand tools, rotary current at increased frequency of 200 or

300 Hz combines high electrical performance with minimal motor weight. As the frequency of the rotary current increases, there is a proportional increase in motor speed and thus in the perfor- mance of asynchronic motors. This is limited by the maximum admissible circumference velocity (operating rotational speed) of the tools. An optimum perfor- mance/weight ratio is achieved by

(Fig. 1). Large differences bet- ween motor rotational speed and operating rotational speed require larger gears. This means that weight savings from the rotary current drive are negated by the increased weight from the stepdown gearing. High-frequency installations using exclusively grinders should be operated at 300 Hz. Using rotary current at increased frequency optimally fulfils the demand for light yet high-performance hand tools.

Stator

Rotor

Housing

Weight (kg)

Total weight

Gear weight

Motor weight

0 | 100 | 200 | 300 | 400 | 500 |

Frequency (Hz)

Fig. 1 The graph shows the dependence of motor and gearing weight on frequency at constant motor performance and rated rotational speed. 300 Hz yields an optimum performance/weight ratio.

64 | 65 |