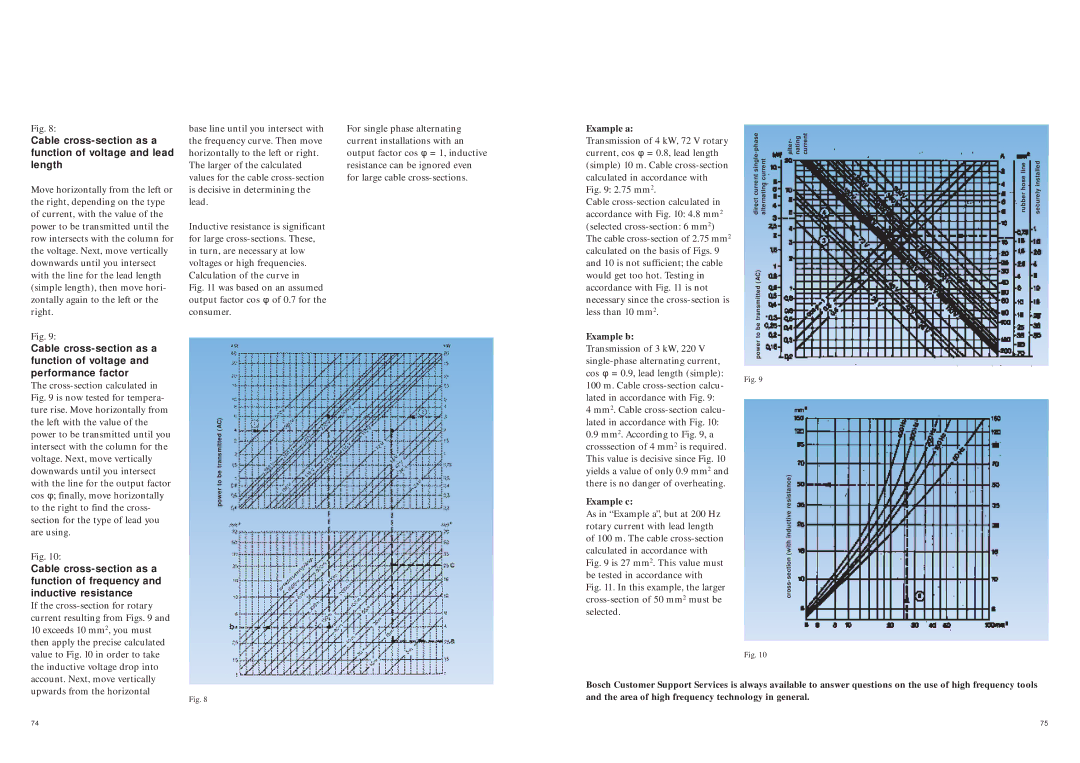

Fig. 8:

Cable cross-section as a function of voltage and lead length

Move horizontally from the left or the right, depending on the type of current, with the value of the power to be transmitted until the row intersects with the column for the voltage. Next, move vertically downwards until you intersect with the line for the lead length (simple length), then move hori- zontally again to the left or the right.

Fig. 9:

Cable

base line until you intersect with the frequency curve. Then move horizontally to the left or right.

The larger of the calculated values for the cable

Inductive resistance is significant for large

Fig. 11 was based on an assumed output factor cos f of 0.7 for the consumer.

For single phase alternating current installations with an output factor cos f = 1, inductive resistance can be ignored even for large cable cross-sections.

Example a:

Transmission of 4 kW, 72 V rotary current, cos f = 0.8, lead length (simple) 10 m. Cable

Cable

The cable

Example b:

Transmission of 3 kW, 220 V

direct current | alter- nating current | rubber hose line | securely installed |

power to be transmitted (AC)

Fig. 9

The

Fig. 10:

Cable

If the

10 exceeds 10 mm2, you must |

then apply the precise calculated |

value to Fig. 10 in order to take |

the inductive voltage drop into |

account. Next, move vertically |

power to be transmitted (AC)

100m. Cable

4mm2. Cable

Example c:

As in “Example a”, but at 200 Hz rotary current with lead length of 100 m. The cable

Fig. 10

upwards from the horizontal |

Fig. 8

Bosch Customer Support Services is always available to answer questions on the use of high frequency tools and the area of high frequency technology in general.

74 | 75 |