ELECTRICAL SAFETY.

For

265 V = 153 V

1.73

At operating voltages of 135 V or 72 V, on the other hand, the dangerous voltage is only

135 V | = 78 V or | |

1.73 |

| |

|

| |

72 V | = 42 V | |

1.73 |

| |

|

| |

The effectiveness of the protective earthing is assured by using corre- spondingly robust plug fixtures of faultless electrical construction

together with suitably resistant cables. Careful maintenance is equally important. The electric tool itself must, in its construction design, be capable of satisfying the stringent demands of indus- trial manufacture. Under normal circumstances, the description provided above, e.g. the protec- tion measure “Earthing" as per VDE 0100 – 10 N is adhered to.

The possible protective measures may be classified and subdivided as follows:

1.0protective measures without switching device

1.1protective insulation (VDE 0100 – § 7 N)

1.2low voltage, 42 V (VDE 0100 – § 8 N)

1.3protective separation (VDE 0100 – § 14 N)

2.0protective measures with switching device

2.1protective earthing (VDE 0100 – § 9 N)

2.2reduction to zero voltage (VDE 0100 – § 10 N)

In cases 2.1 and 2.2,

The greatest possible degree of protection is reached by using fault current (FI) circuit breakers in addition.

Protective insulation as per 1.1 is not applied to

Here we wish to focus on the protective measure “reduction to zero voltage as per 2.2" since it finds application primarily with

conductor that is in turn connec- ted to the neutral conductor.

The protective measure “reduction to zero voltage" thus switches off defective installation parts since the inline fuse directly before the defective location is activated.

If the fuse is really to be activated, certain voltage reduction condi- tions as per VDE 0100 – § 10 N must be complied with. The most important voltage reduction requirement: The

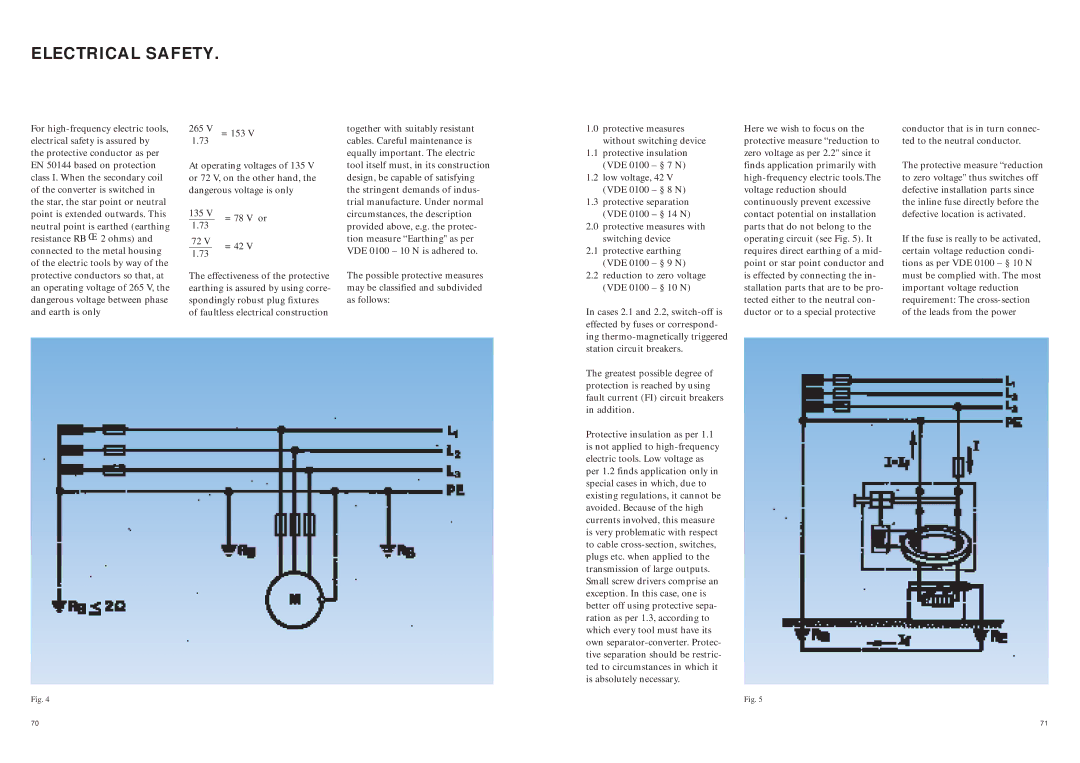

Fig. 4

Fig. 5

70 | 71 |