BM 2610933969 09-12_BM 2610933969 09-12.qxp 9/20/12 9:19 AM Page 9

Assembly

SELECTING BITS

A wide assortment of router bits with different profiles are available as accessories. Use 1/2" shank whenever possible, and only use good quality bits.

To prevent personal injury, ! WARNING always remove the plug from

power source before removing or installing bits or accessories.

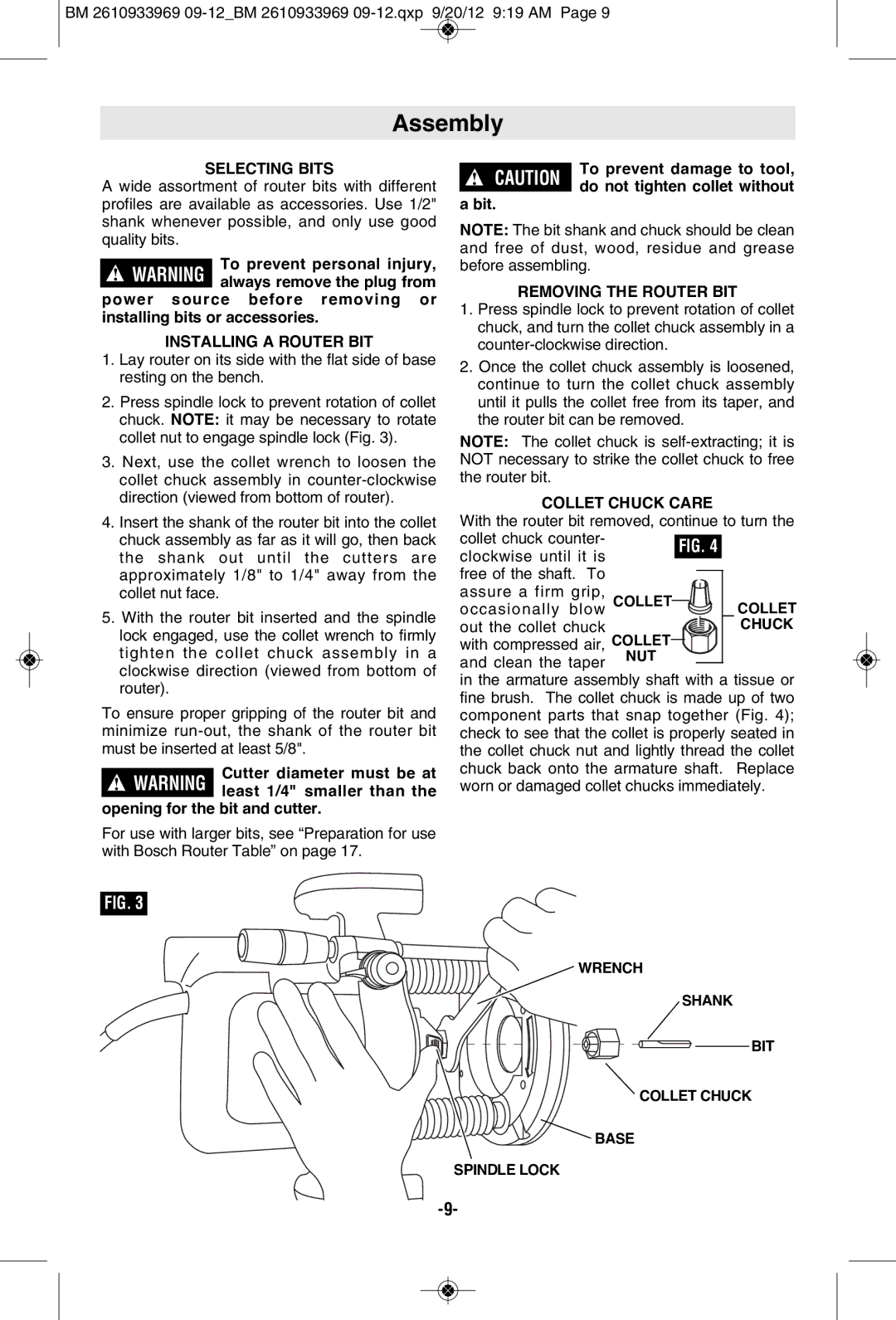

INSTALLING A ROUTER BIT

1.Lay router on its side with the flat side of base resting on the bench.

2.Press spindle lock to prevent rotation of collet chuck. NOTE: it may be necessary to rotate collet nut to engage spindle lock (Fig. 3).

3.Next, use the collet wrench to loosen the collet chuck assembly in

4.Insert the shank of the router bit into the collet chuck assembly as far as it will go, then back the shank out until the cutters are approximately 1/8" to 1/4" away from the collet nut face.

5.With the router bit inserted and the spindle lock engaged, use the collet wrench to firmly tighten the collet chuck assembly in a clockwise direction (viewed from bottom of router).

To ensure proper gripping of the router bit and minimize

Cutter diameter must be at least 1/4" smaller than the

opening for the bit and cutter.

For use with larger bits, see “Preparation for use with Bosch Router Table” on page 17.

! CAUTION | To prevent damage to tool, | |

| do not tighten collet without | |

a bit. | ||

|

NOTE: The bit shank and chuck should be clean and free of dust, wood, residue and grease before assembling.

REMOVING THE ROUTER BIT

1.Press spindle lock to prevent rotation of collet chuck, and turn the collet chuck assembly in a

2.Once the collet chuck assembly is loosened, continue to turn the collet chuck assembly until it pulls the collet free from its taper, and the router bit can be removed.

NOTE: The collet chuck is

COLLET CHUCK CARE

With the router bit removed, continue to turn the

collet chuck counter- |

| FIG. 4 |

clockwise until it is |

| |

|

| |

free of the shaft. To |

|

|

assure a firm grip, | COLLET |

|

occasionally blow | COLLET | |

out the collet chuck | COLLET | CHUCK |

with compressed air, |

| |

and clean the taper | NUT |

|

in the armature assembly shaft with a tissue or fine brush. The collet chuck is made up of two component parts that snap together (Fig. 4); check to see that the collet is properly seated in the collet chuck nut and lightly thread the collet chuck back onto the armature shaft. Replace worn or damaged collet chucks immediately.

FIG. 3

WRENCH

SHANK

BIT

COLLET CHUCK

BASE

SPINDLE LOCK