BM 2610933969 09-12_BM 2610933969 09-12.qxp 9/20/12 9:19 AM Page 12

MAKING PROGESSIVELY DEEPER

PLUNGE CUTS

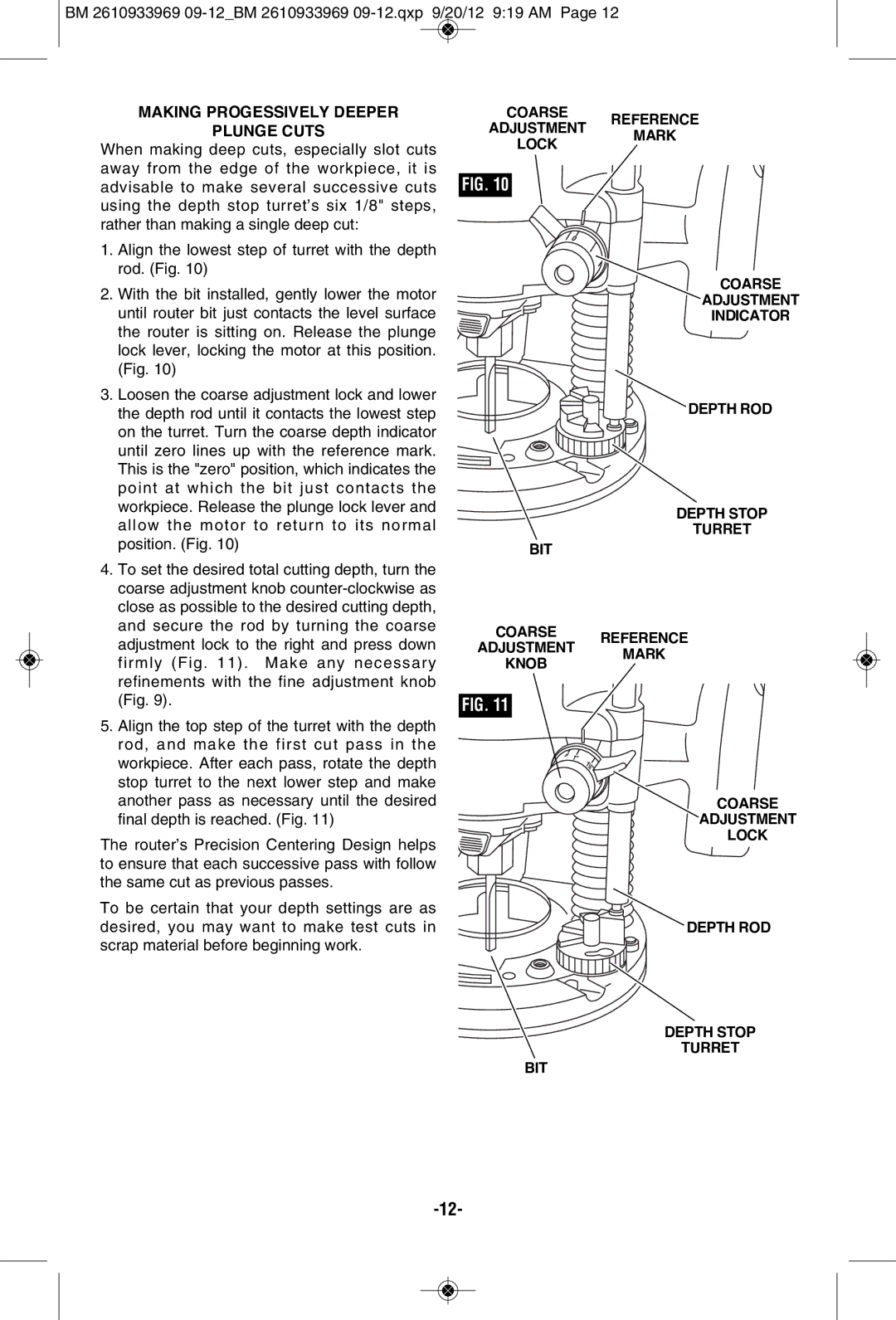

When making deep cuts, especially slot cuts away from the edge of the workpiece, it is advisable to make several successive cuts using the depth stop turret’s six 1/8" steps, rather than making a single deep cut:

COARSE REFERENCE

ADjUSTMENT MARK LOCK

FIG. 10

1.Align the lowest step of turret with the depth rod. (Fig. 10)

2.With the bit installed, gently lower the motor until router bit just contacts the level surface the router is sitting on. Release the plunge lock lever, locking the motor at this position. (Fig. 10)

3.Loosen the coarse adjustment lock and lower the depth rod until it contacts the lowest step on the turret. Turn the coarse depth indicator until zero lines up with the reference mark. This is the "zero" position, which indicates the point at which the bit just contacts the workpiece. Release the plunge lock lever and allow the motor to return to its normal position. (Fig. 10)

4.To set the desired total cutting depth, turn the coarse adjustment knob

5.Align the top step of the turret with the depth rod, and make the first cut pass in the workpiece. After each pass, rotate the depth stop turret to the next lower step and make another pass as necessary until the desired final depth is reached. (Fig. 11)

The router’s Precision Centering Design helps to ensure that each successive pass with follow the same cut as previous passes.

To be certain that your depth settings are as desired, you may want to make test cuts in scrap material before beginning work.

BIT

COARSE

ADjUSTMENT

KNOB

FIG. 11

BIT

COARSE

ADjUSTMENT

INDICATOR

DEPTH ROD

DEPTH STOP

TURRET

REFERENCE

MARK

COARSE

ADjUSTMENT

LOCK

DEPTH ROD

DEPTH STOP

TURRET