7. Blade

Use only 12” blades with 1” arbor hole.

8. Fence

Supports the workpiece. The fence has a cast in scale to make repetitive cuts easy. The fence also has holes which are used to secure an auxiliary fence if desired.

9. Kerf Insert

Minimizes workpiece

10. Tool Mounting Pads

The four corners of the saw provide areas to clamp, bolt or nail the saw to a flat work surface.

11. Detent Override

Allows detent action to be locked out allowing for micro adjustments to any miter angle.

12. Miter Lock Knob

The miter lock knob locks the miter saw table at any desired miter angle.

13. Miter Detent Trigger

The trigger releases the table from the detent.

14. Miter Scale

This scale is cast in on the base of the saw. Allows you to read the miter angles easily.

15. Detents

There are nine (9) miter detents for fast and accurate miter cuts of common miter angles.

16. Table

Sits in base, provides workpiece support, rotates for desired miter cuts and rotates the head assembly.

17. Quick Action Clamp Positions

There are six (6) positions behind the fence for the quick action clamp.

18. Base

Provides working surface to support workpiece.

19.Accessory Extension/Stop Holes (Standard Type) Machined holes that accept the extension/stop accessory.

20.Accessory Pipe Extension/Stop Holes

Machined holes that accept the pipe extension/stop accessory.

21. Sliding Base

This provides extra support and clamping area for compound miter cuts.

22. Sliding Fence

Provides maximum height support for the workpiece and slides to left for easy compound cuts.

23. Lock Pin

The compound miter saw is equipped with a lock pin used to lock the head assembly in the lower position.

24. Dust Chute Elbow

The dust chute elbow rotates 360º and can accommodate the dust bag or a

25. Chip Deflector

This protects against large chips from entering the upper guard.

26. Lower Guard Actuation Link

Allows for smooth movement of the lower guard.

27. Upper Blade Guard

Covers upper portion of the blade.

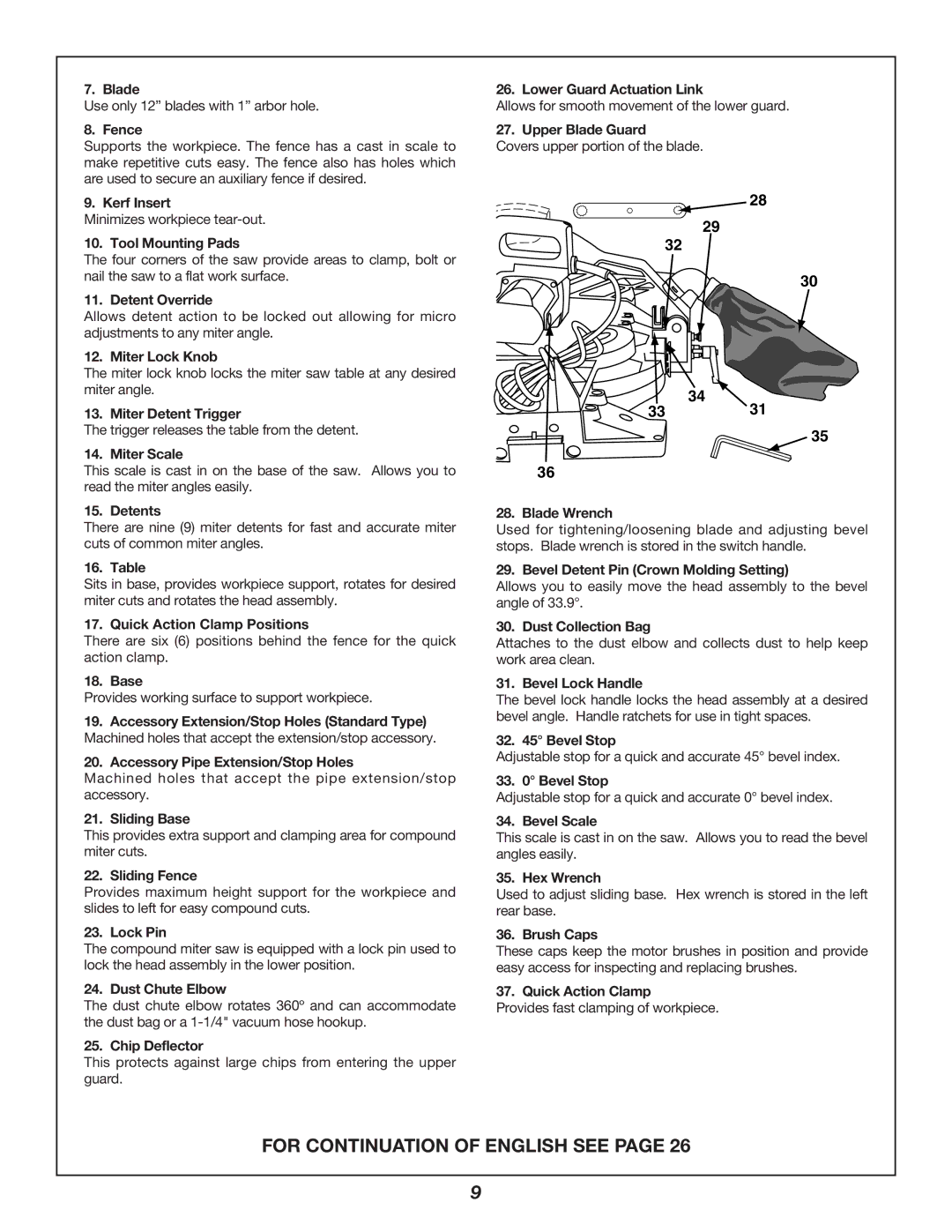

28

29

32

30

34

3331  35

35

36

28. Blade Wrench

Used for tightening/loosening blade and adjusting bevel stops. Blade wrench is stored in the switch handle.

29. Bevel Detent Pin (Crown Molding Setting)

Allows you to easily move the head assembly to the bevel angle of 33.9°.

30. Dust Collection Bag

Attaches to the dust elbow and collects dust to help keep work area clean.

31. Bevel Lock Handle

The bevel lock handle locks the head assembly at a desired bevel angle. Handle ratchets for use in tight spaces.

32. 45° Bevel Stop

Adjustable stop for a quick and accurate 45° bevel index.

33. 0° Bevel Stop

Adjustable stop for a quick and accurate 0° bevel index.

34. Bevel Scale

This scale is cast in on the saw. Allows you to read the bevel angles easily.

35. Hex Wrench

Used to adjust sliding base. Hex wrench is stored in the left rear base.

36. Brush Caps

These caps keep the motor brushes in position and provide easy access for inspecting and replacing brushes.

37. Quick Action Clamp

Provides fast clamping of workpiece.

FOR CONTINUATION OF ENGLISH SEE PAGE 26

9