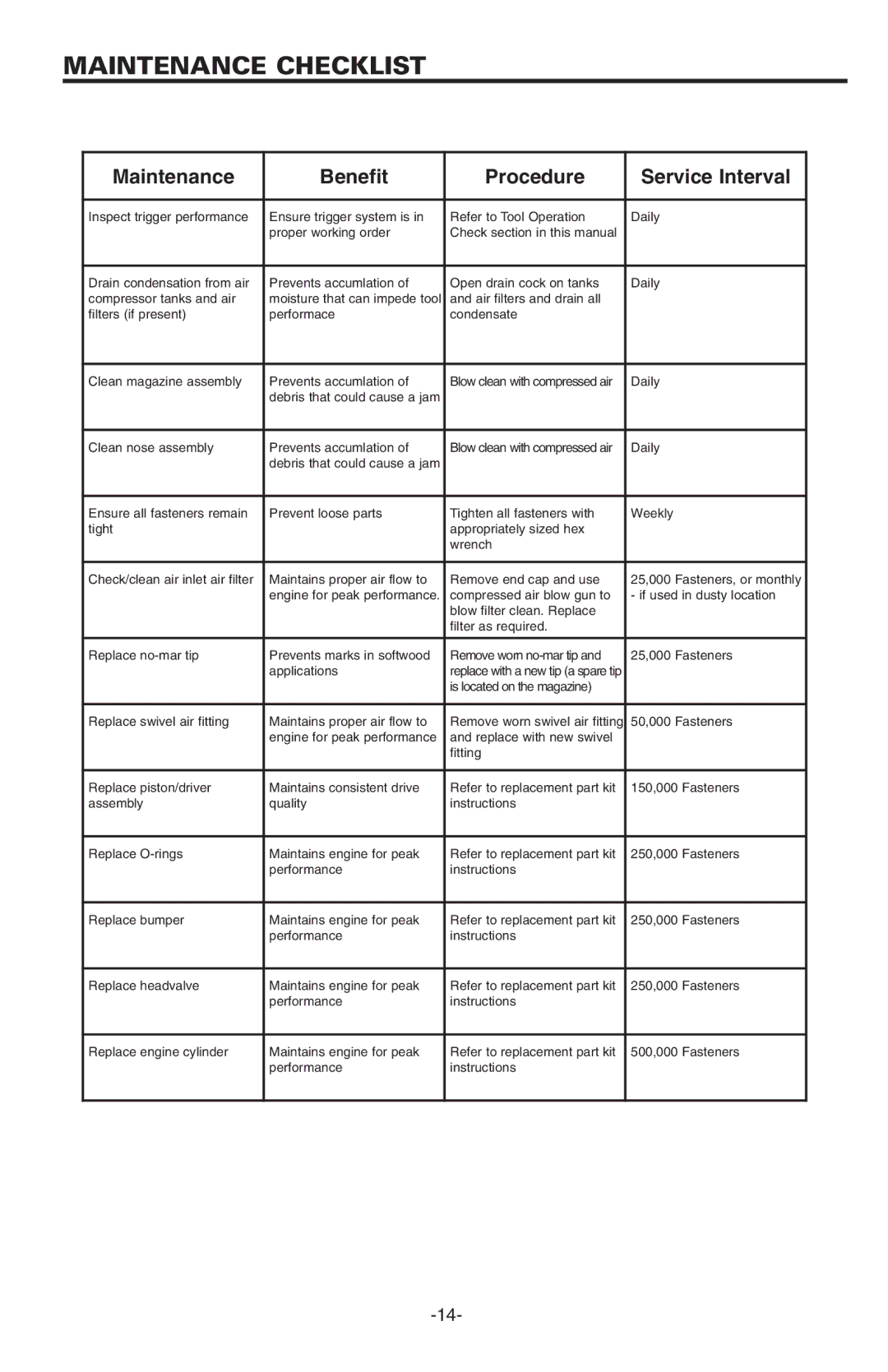

MAINTENANCE CHECKLIST

Maintenance | Benefit | Procedure | Service Interval |

|

|

|

|

Inspect trigger performance | Ensure trigger system is in | Refer to Tool Operation | Daily |

| proper working order | Check section in this manual |

|

|

|

|

|

Drain condensation from air | Prevents accumlation of | Open drain cock on tanks | Daily |

compressor tanks and air | moisture that can impede tool | and air filters and drain all |

|

filters (if present) | performace | condensate |

|

|

|

|

|

Clean magazine assembly | Prevents accumlation of | Blow cleanwith compressed air | Daily |

| debris that could cause a jam |

|

|

|

|

|

|

Clean nose assembly | Prevents accumlation of | Blow cleanwith compressed air | Daily |

| debris that could cause a jam |

|

|

|

|

|

|

Ensure all fasteners remain | Prevent loose parts | Tighten all fasteners with | Weekly |

tight |

| appropriately sized hex |

|

|

| wrench |

|

|

|

|

|

Check/clean air inlet air filter | Maintains proper air flow to | Remove end cap and use | 25,000 Fasteners, or monthly |

| engine for peak performance. | compressed air blow gun to | - if used in dusty location |

|

| blow filter clean. Replace |

|

|

| filter as required. |

|

|

|

|

|

Replace | Prevents marks in softwood | Removeworn | 25,000 Fasteners |

| applications | replace with a new tip (a spare tip |

|

|

| is located on the magazine) |

|

|

|

|

|

Replace swivel air fitting | Maintains proper air flow to | Remove worn swivel air fitting | 50,000 Fasteners |

| engine for peak performance | and replace with new swivel |

|

|

| fitting |

|

|

|

|

|

Replace piston/driver | Maintains consistent drive | Refer to replacement part kit | 150,000 Fasteners |

assembly | quality | instructions |

|

|

|

|

|

Replace | Maintains engine for peak | Refer to replacement part kit | 250,000 Fasteners |

| performance | instructions |

|

|

|

|

|

Replace bumper | Maintains engine for peak | Refer to replacement part kit | 250,000 Fasteners |

| performance | instructions |

|

|

|

|

|

Replace headvalve | Maintains engine for peak | Refer to replacement part kit | 250,000 Fasteners |

| performance | instructions |

|

|

|

|

|

Replace engine cylinder | Maintains engine for peak | Refer to replacement part kit | 500,000 Fasteners |

| performance | instructions |

|

|

|

|

|