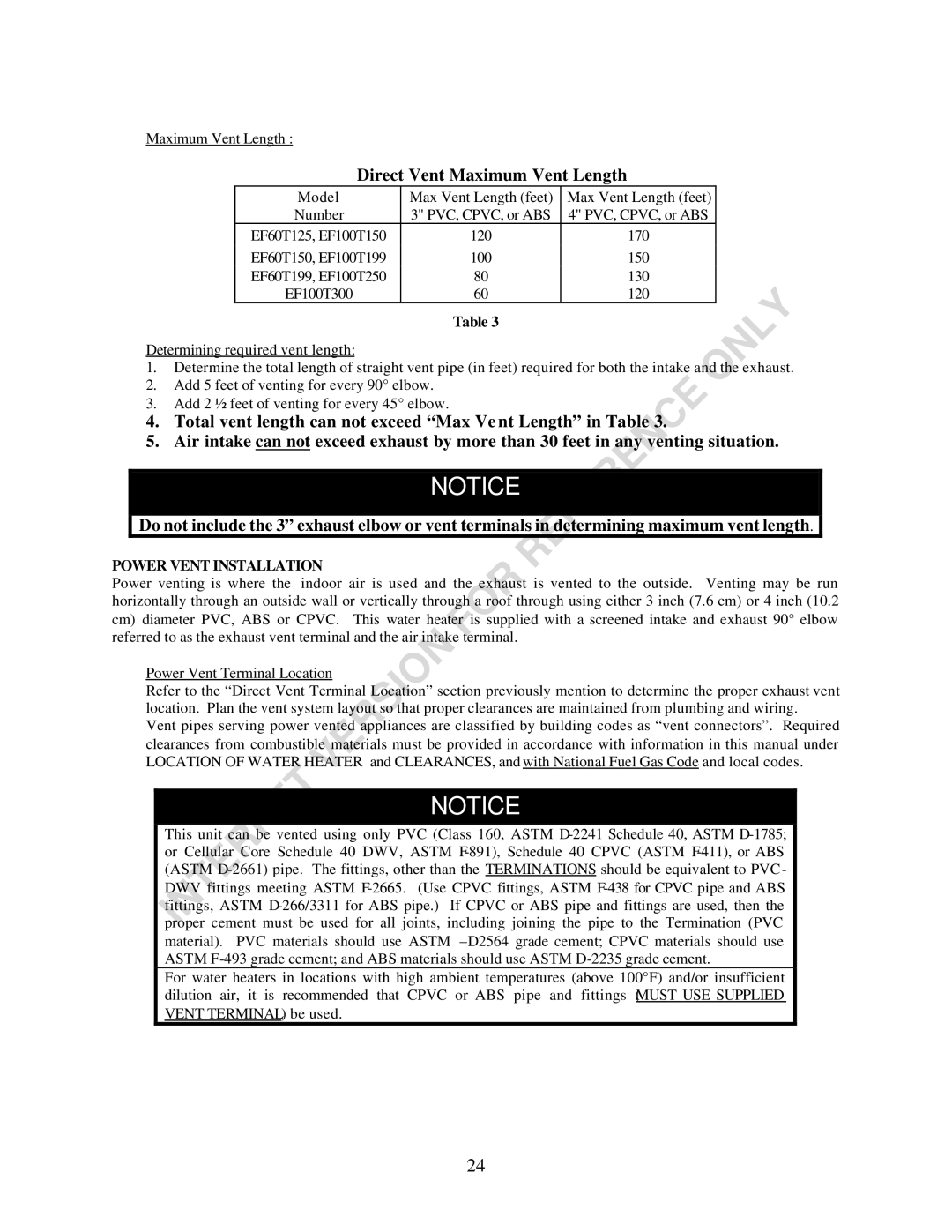

Maximum Vent Length :

Direct Vent Maximum Vent Length

Model | Max Vent Length (feet) | Max Vent Length (feet) |

Number | 3" PVC, CPVC, or ABS | 4" PVC, CPVC, or ABS |

EF60T125, EF100T150 | 120 | 170 |

EF60T150, EF100T199 | 100 | 150 |

EF60T199, EF100T250 | 80 | 130 |

EF100T300 | 60 | 120 |

Table 3

Determining required vent length:

1.Determine the total length of straight vent pipe (in feet) required for both the intake and the exhaust.

2.Add 5 feet of venting for every 90° elbow.

3.Add 2 ½ feet of venting for every 45° elbow.

4.Total vent length can not exceed “Max Ve nt Length” in Table 3.

5.Air intake can not exceed exhaust by more than 30 feet in any venting situation.

NOTICE

Do not include the 3” exhaust elbow or vent terminals in determining maximum vent length.

POWER VENT INSTALLATION

Power venting is where the indoor air is used and the exhaust is vented to the outside. Venting may be run horizontally through an outside wall or vertically through a roof through using either 3 inch (7.6 cm) or 4 inch (10.2 cm) diameter PVC, ABS or CPVC. This water heater is supplied with a screened intake and exhaust 90° elbow referred to as the exhaust vent terminal and the air intake terminal.

Power Vent Terminal Location

Refer to the “Direct Vent Terminal Location” section previously mention to determine the proper exhaust vent location. Plan the vent system layout so that proper clearances are maintained from plumbing and wiring.

Vent pipes serving power vented appliances are classified by building codes as “vent connectors”. Required clearances from combustible materials must be provided in accordance with information in this manual under LOCATION OF WATER HEATER and CLEARANCES, and with National Fuel Gas Code and local codes.

NOTICE

This unit can be vented using only PVC (Class 160, ASTM

For water heaters in locations with high ambient temperatures (above 100°F) and/or insufficient dilution air, it is recommended that CPVC or ABS pipe and fittings (MUST USE SUPPLIED VENT TERMINAL) be used.

24