5.Install concentric Y fitting and pipe assembly through the structure’s hole and field

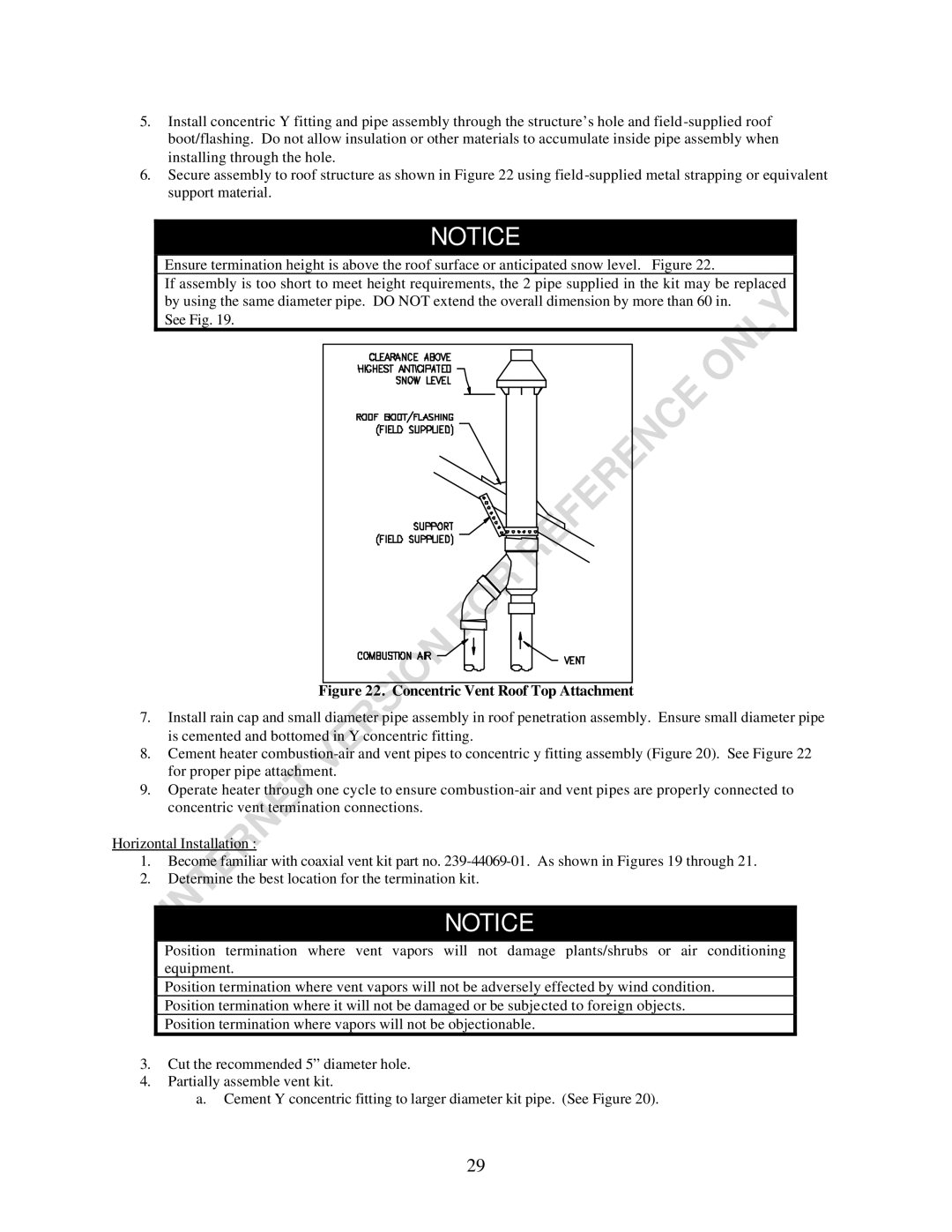

6.Secure assembly to roof structure as shown in Figure 22 using field

NOTICE

Ensure termination height is above the roof surface or anticipated snow level. Figure 22.

If assembly is too short to meet height requirements, the 2 pipe supplied in the kit may be replaced by using the same diameter pipe. DO NOT extend the overall dimension by more than 60 in.

See Fig. 19.

Figure 22. Concentric Vent Roof Top Attachment

7.Install rain cap and small diameter pipe assembly in roof penetration assembly. Ensure small diameter pipe is cemented and bottomed in Y concentric fitting.

8.Cement heater

9.Operate heater through one cycle to ensure

Horizontal Installation :

1.Become familiar with coaxial vent kit part no.

2.Determine the best location for the termination kit.

NOTICE

Position termination where vent vapors will not damage plants/shrubs or air conditioning equipment.

Position termination where vent vapors will not be adversely effected by wind condition.

Position termination where it will not be damaged or be subjected to foreign objects.

Position termination where vapors will not be objectionable.

3.Cut the recommended 5” diameter hole.

4.Partially assemble vent kit.

a. Cement Y concentric fitting to larger diameter kit pipe. (See Figure 20).

29